Inverted separating type bucket scattering device

A material spreading device, a separate technology, applied in the directions of loading/unloading, transportation and packaging, conveyors, etc., can solve the problems of uneven material spreading, large total weight, large mechanism vibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

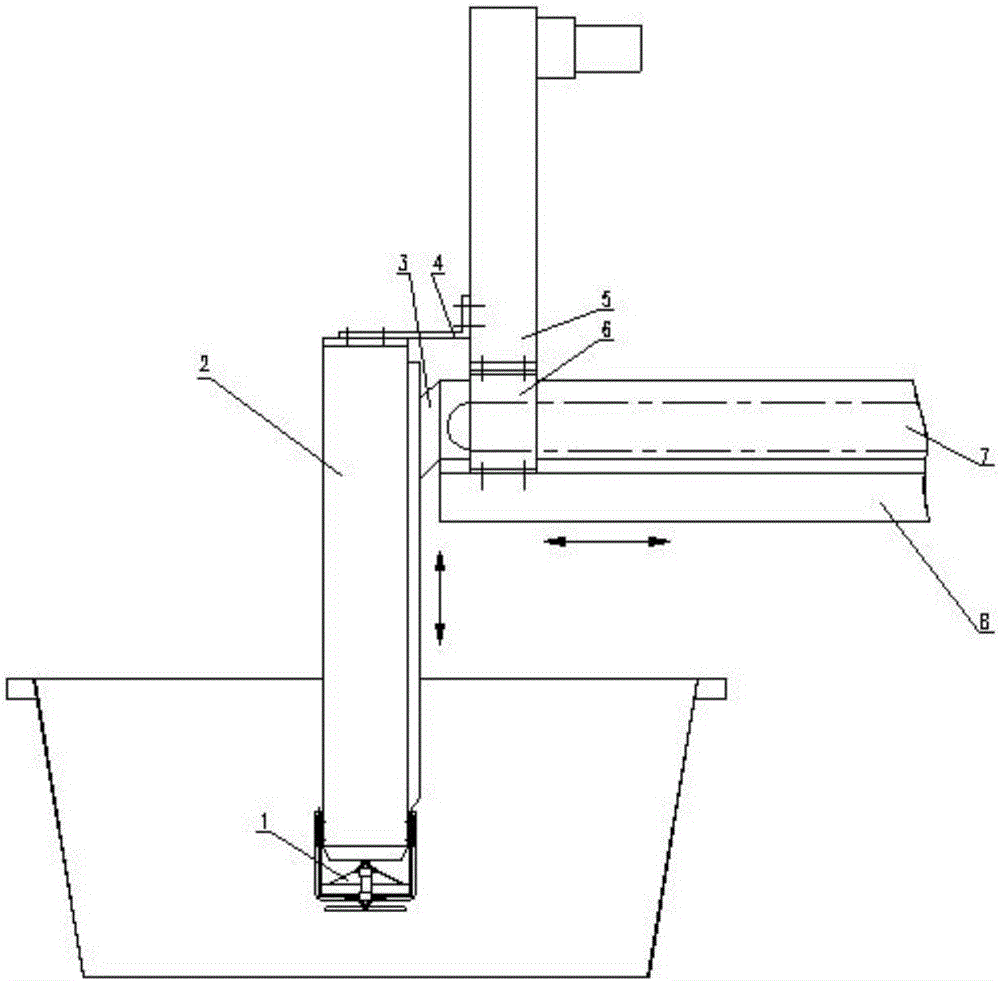

[0023] An inverted and separated barrel-type material spreading device, including an electric material spreading device 1, a lifting and lowering material spreading bucket 2, a hopper 3, a connecting bracket 4, a lifting device 5, a connecting seat 6, a chain conveyor 7 and a telescopic arm 8 ;

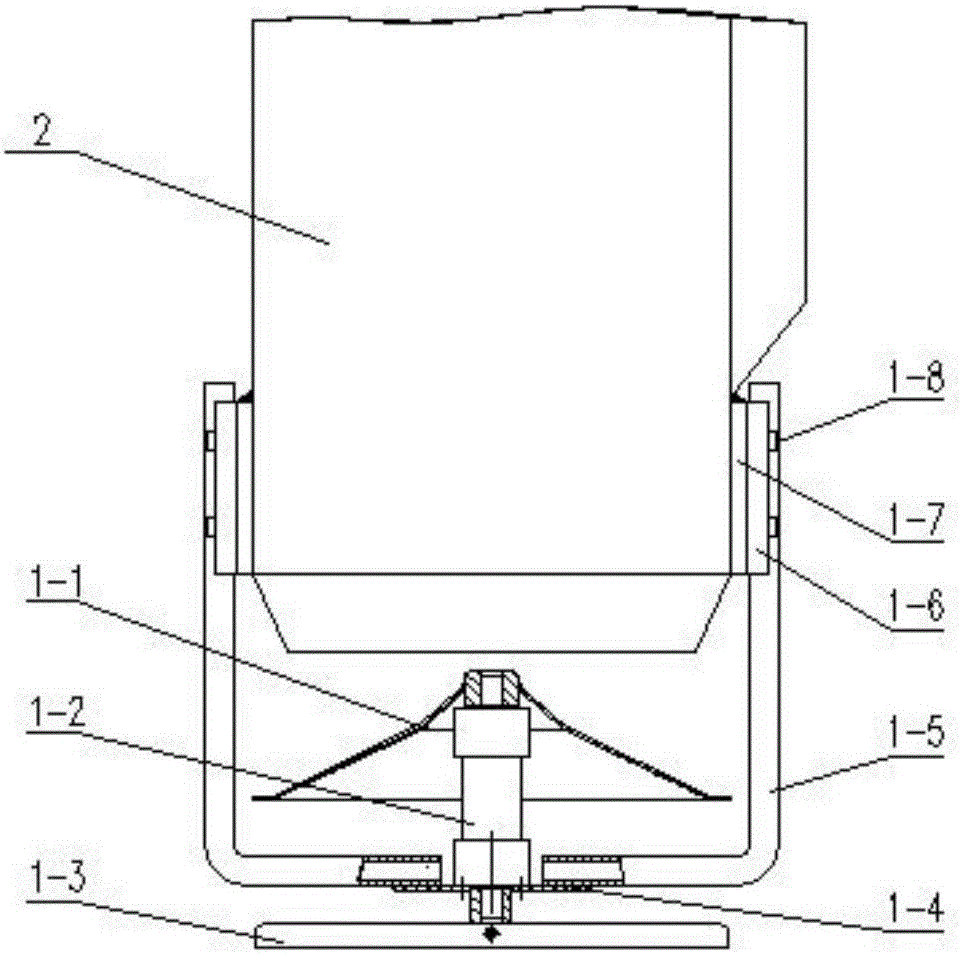

[0024] The electric spreading device 1 is installed at the lower end of the lifting spreading barrel 2;

[0025] The lifting and spreading bucket 2 is connected with the lifting device 5 through the connecting bracket 4 at its top, and is driven by the lifting device 5 for vertical lifting movement;

[0026] The lifting device 5 is fixed on the telescopic arm 8 through the connection base 6 .

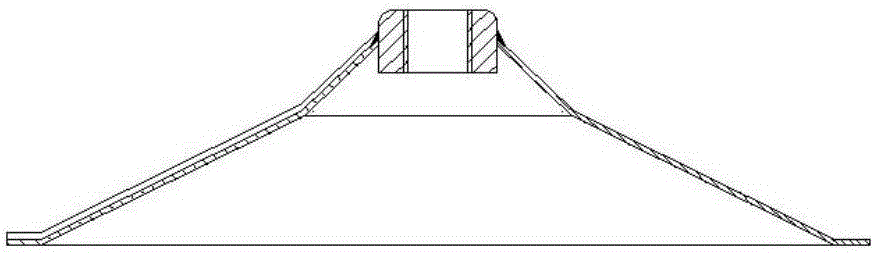

[0027] The electric spreading device 1 includes a spreading plate 1-1, a double output shaft motor 1-2, a material bracket 1-3, a connecting piece 1-4, a hollow pull rod 1-5, a rod connecting plate 1-6, a bucket connecting plate 1-7 and screw 1-8;

[0028] One output shaft of the double outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com