Article sorting system package loading method, article sorting package loading system and sorting system

A technology for items and packages, applied in sorting and other directions, can solve the problems of stable sorting of abnormal parts, increase operating procedures, and high labor costs, and achieve the effect of improving packaging efficiency, high automation, and calculation and control assurance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0065] When the above-mentioned item picking system is packaged, the following steps are included:

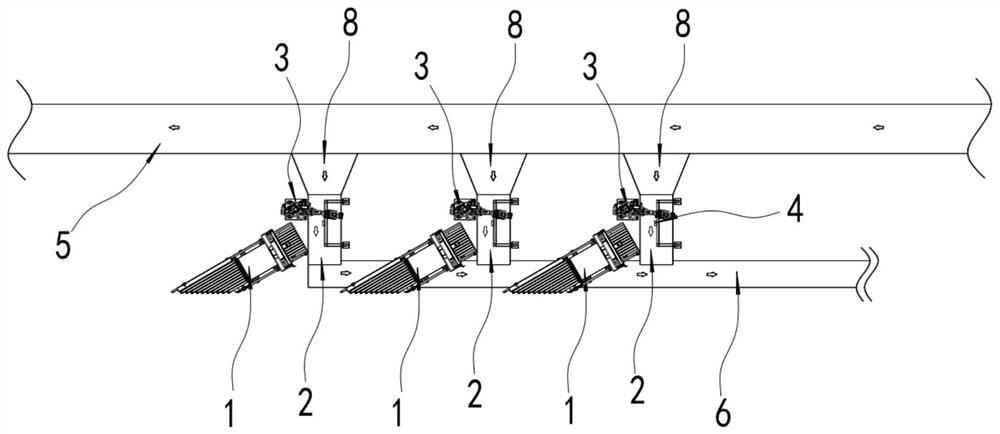

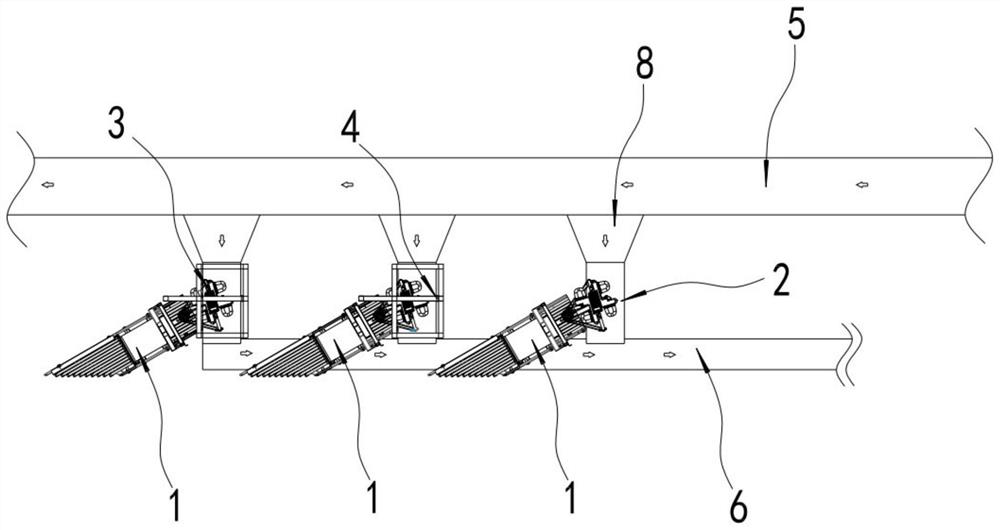

[0066] S1, a batch of articles is introduced into the chute 8 from the upper conveying line 5 manually or by automated equipment, and the articles enter the sorting conveying line 2 from the chute 8 . Specifically, the items on the truck are unloaded onto the upper conveyor line 5, and the upper conveyor line 5 transports the items to the direction of the chute 8. When the items move to the position corresponding to the chute 8, the A batch of articles is introduced into the chute 8 by a transfer device or manually, and the articles enter the sorting conveying line 2 from the chute 8 .

[0067] S2, the picking conveying line 2 transports a batch of items to the image collection range of the 3D camera 4 above the picking conveying line 2 and then stops, and the picking conveying line can stop after conveying a fixed distance or at the first When the item moves to the detection ...

Embodiment 3

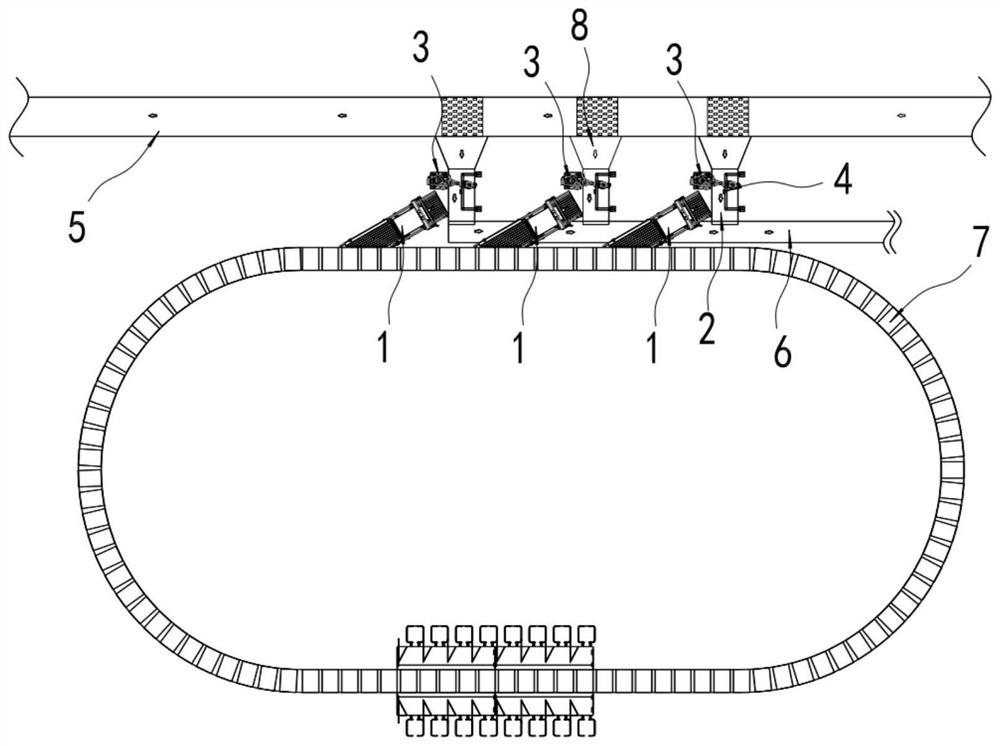

[0075] This solution further discloses a sorting system, including the above-mentioned item picking and packing system, and the sorting line can be a cross-belt sorting line or a flap type sorting line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com