Distributing pipe inlet device for high water tank

A shunt pipe and pool technology, applied in the field of hydraulic construction, can solve the problems of suction, shunt pipe vibration, suction vortex, etc., and achieve the effects of reducing the degree of air entrainment, suppressing the formation of suction belts, and having a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

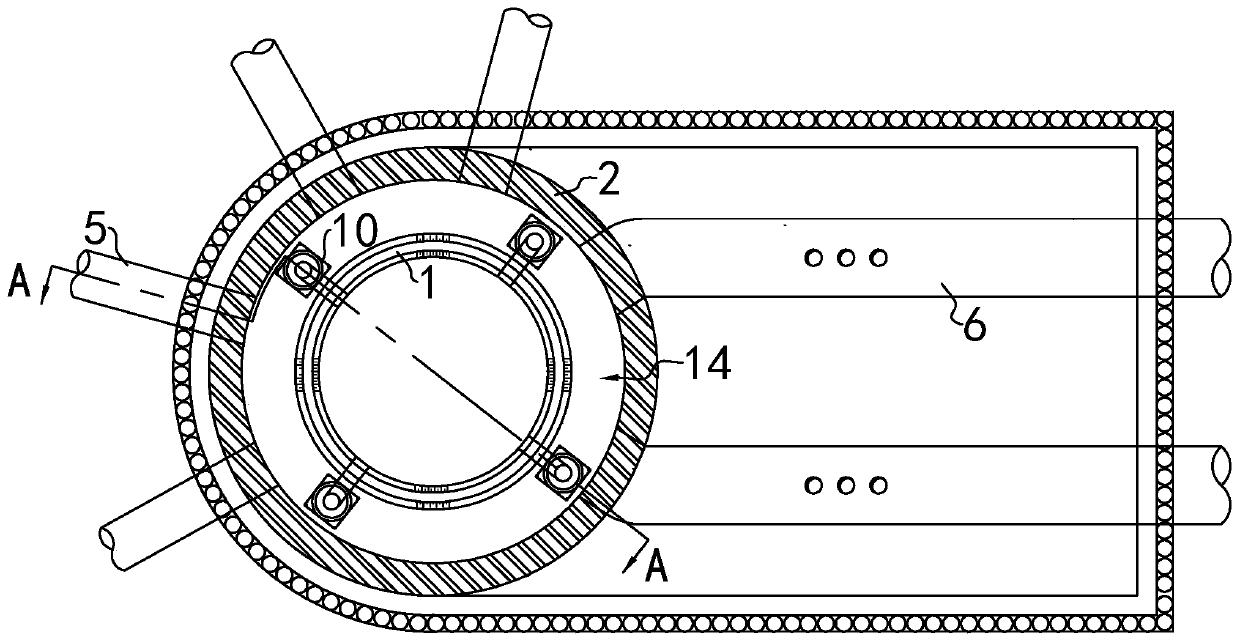

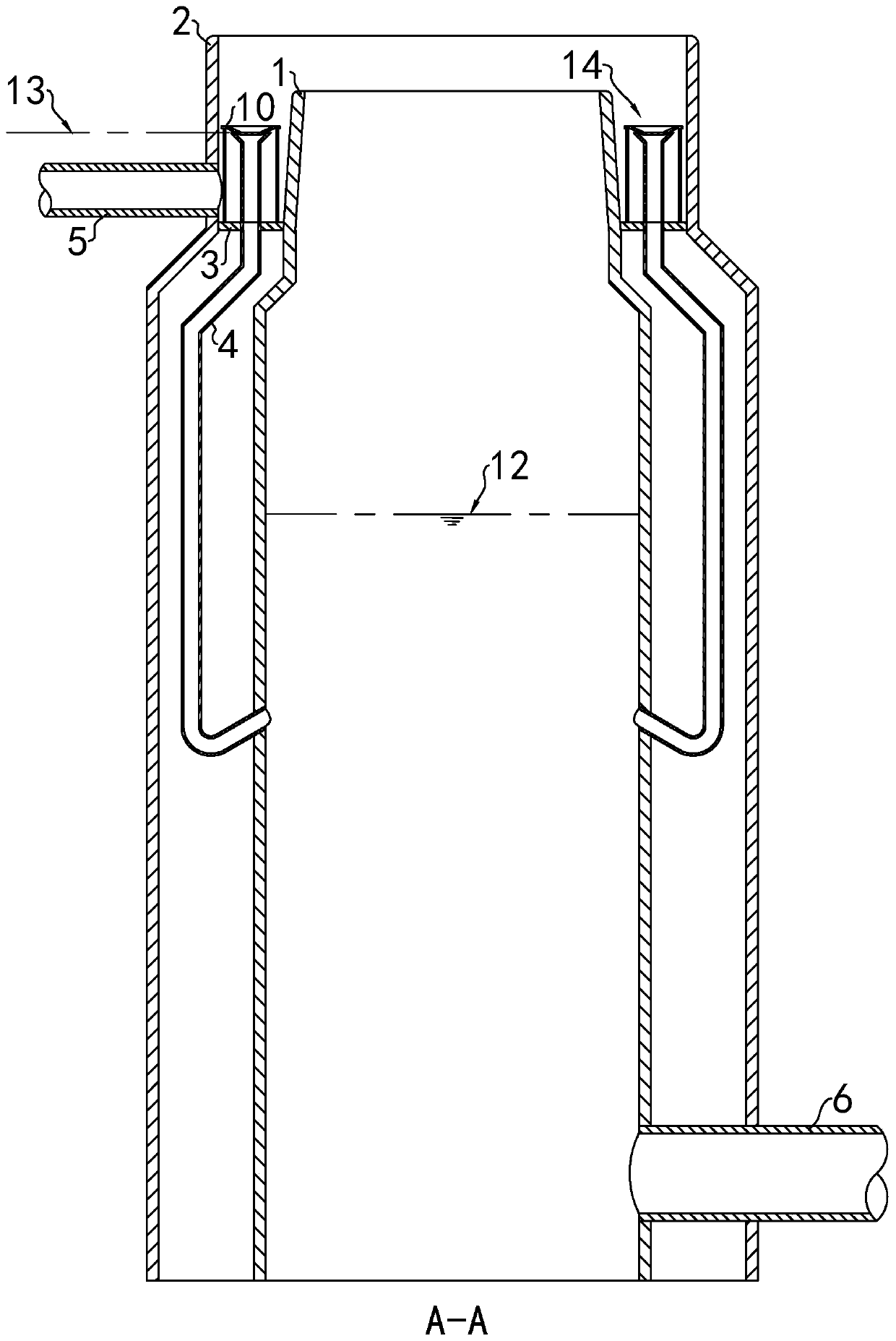

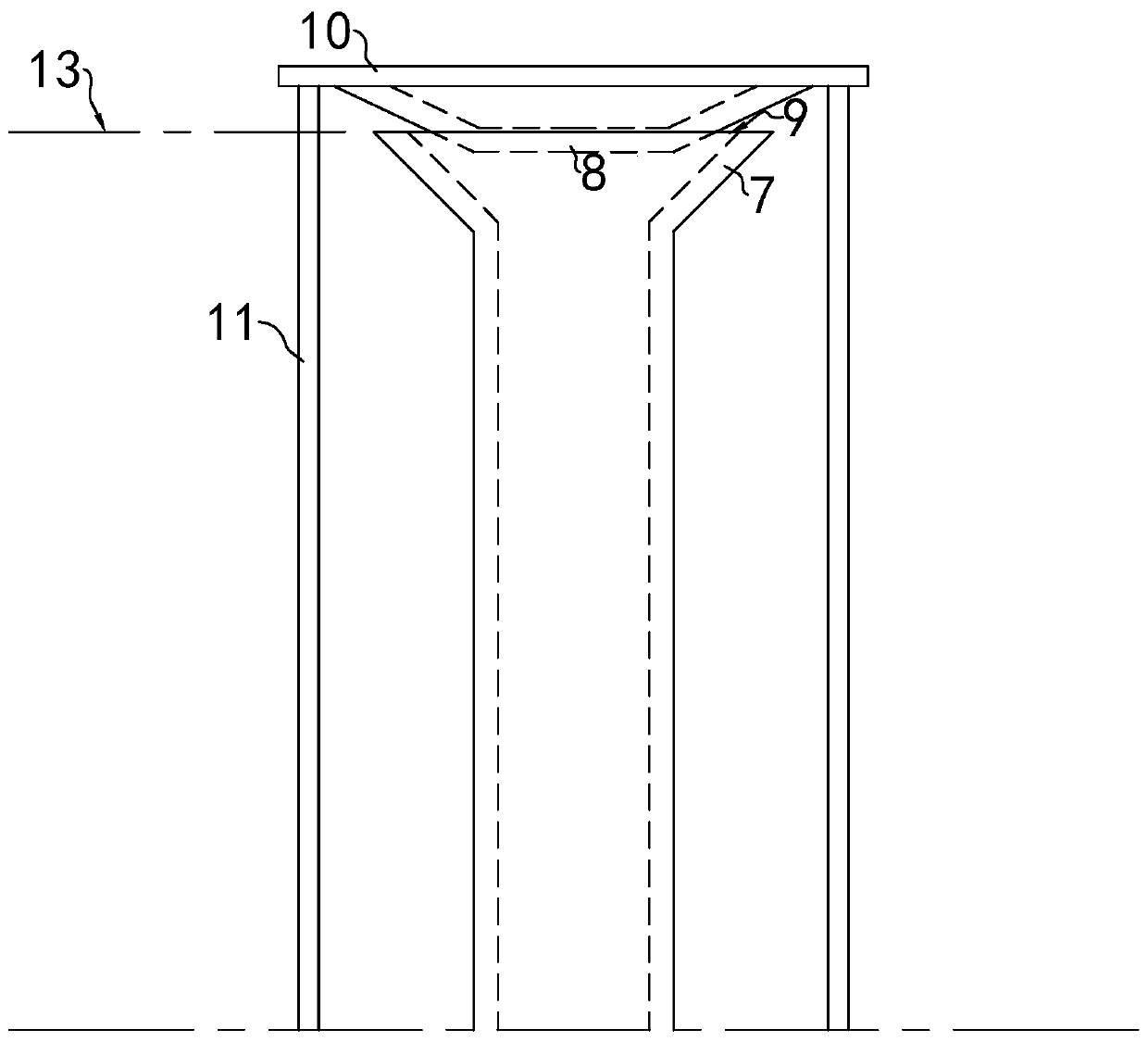

[0022] refer to Figures 1 to 5 , a shunt pipe inlet device for a high-level pool, including a pipe body and a bracket; one end of the pipe body communicates with the shunt pipe 4 of the high-level pool and the other end of the pipe body is provided with a nozzle 7, and the nozzle 7 is located in the high-level pool In the overflow tank 14; the bracket includes a raised portion 8 fixed outside the nozzle 7, the radial dimension of the nozzle 7 gradually expands from the inside of the pipe body, and the raised portion 8 protrudes into the nozzle 7, and the protrusion A flow gap 9 is provided between the portion 8 and the inner side of the nozzle 7 .

[0023] Preferably, the bracket includes a cover plate 10 , and the center of the cover plate 10 protrudes toward one side of the cover plate 10 to form a raised portion 8 .

[0024] Preferably, the bracket further includes several uprights 11, one end of the uprights 11 intersects with the cover plate 10 and the other end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com