Stone remover for biomass briquette production system

A technology for forming fuel and production system, which is applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of mixing stones, affecting the combustion performance of fuel, etc., and achieve good separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

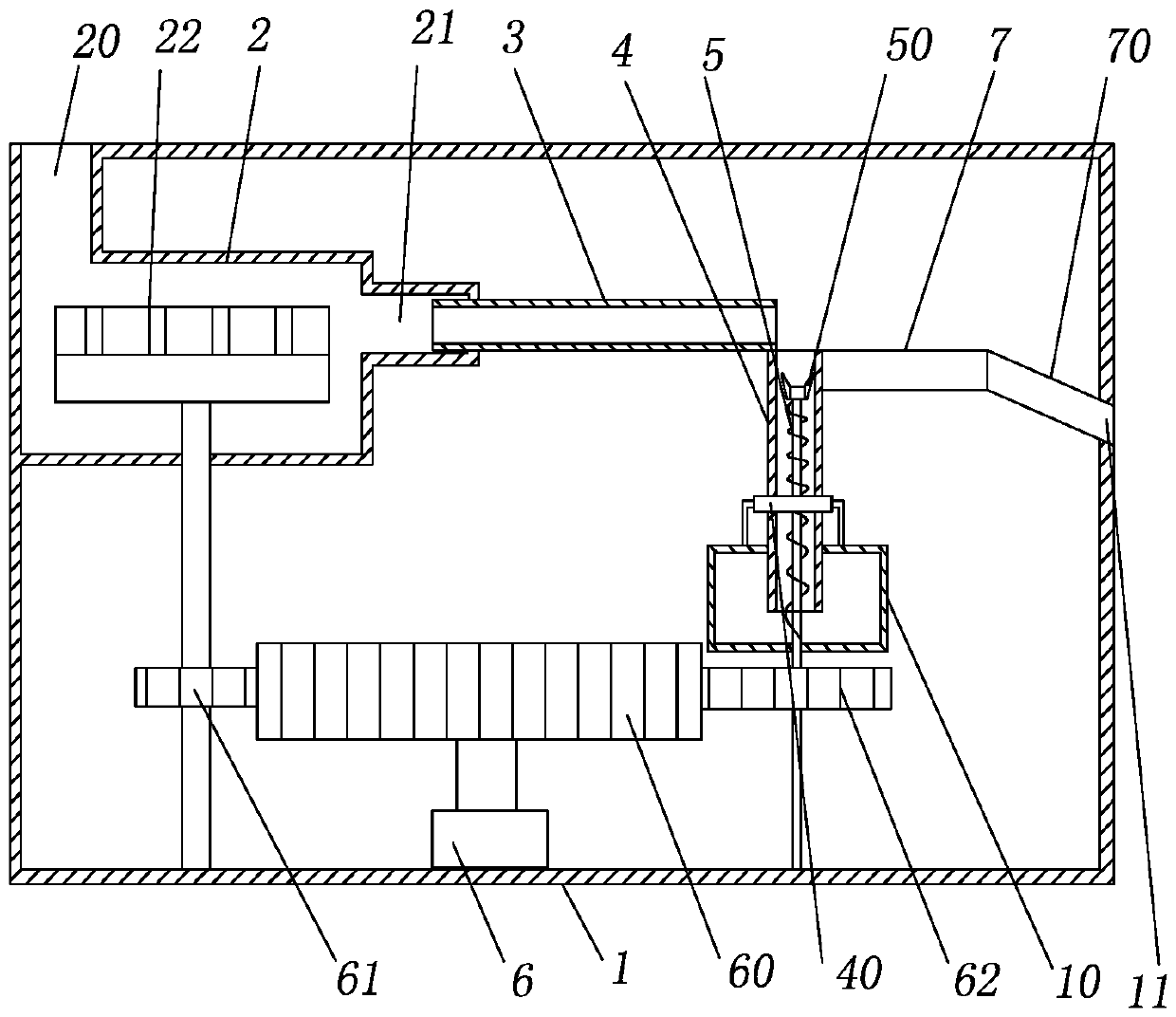

[0018] The reference signs in the accompanying drawings of the description include: stone removal box 1, feeding box 10, discharge port 11, bellows 2, air inlet 20, air outlet 21, impeller 22, long straight pipe 3, short straight pipe 4, fixed ring 40, screw rod 5, stone retaining portion 50, motor 6, central gear 60, impeller gear 61, screw rod gear 62, powder material plate 7, stone plate 70.

[0019] The embodiment is basically as attached figure 1 Shown: a stone remover for a biomass briquette fuel production system, including a stone remover box 1, which is provided with a feeding box 10, a spray removal mechanism, a power mechanism, a material distribution plate and a discharge port 11; The mechanism includes a blowing part and a blowing part, the blowing part includes a bellows 2 and an impeller 22, the bellows 2 is provided with an air inlet 20 and an air outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com