A metal-based ignition power device

A technology of power plant and base point, applied in the field of ignition power plant, can solve the problems of inability to fundamentally eliminate the explosion phenomenon, poor practicability and safety, etc., and achieve the effects of simple structure, high ignition reliability and long injection distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] First of all, it should be explained that the orientation words such as left and right in the present invention are only described according to the accompanying drawings for easy understanding, and are not intended to limit the technical solution of the present invention.

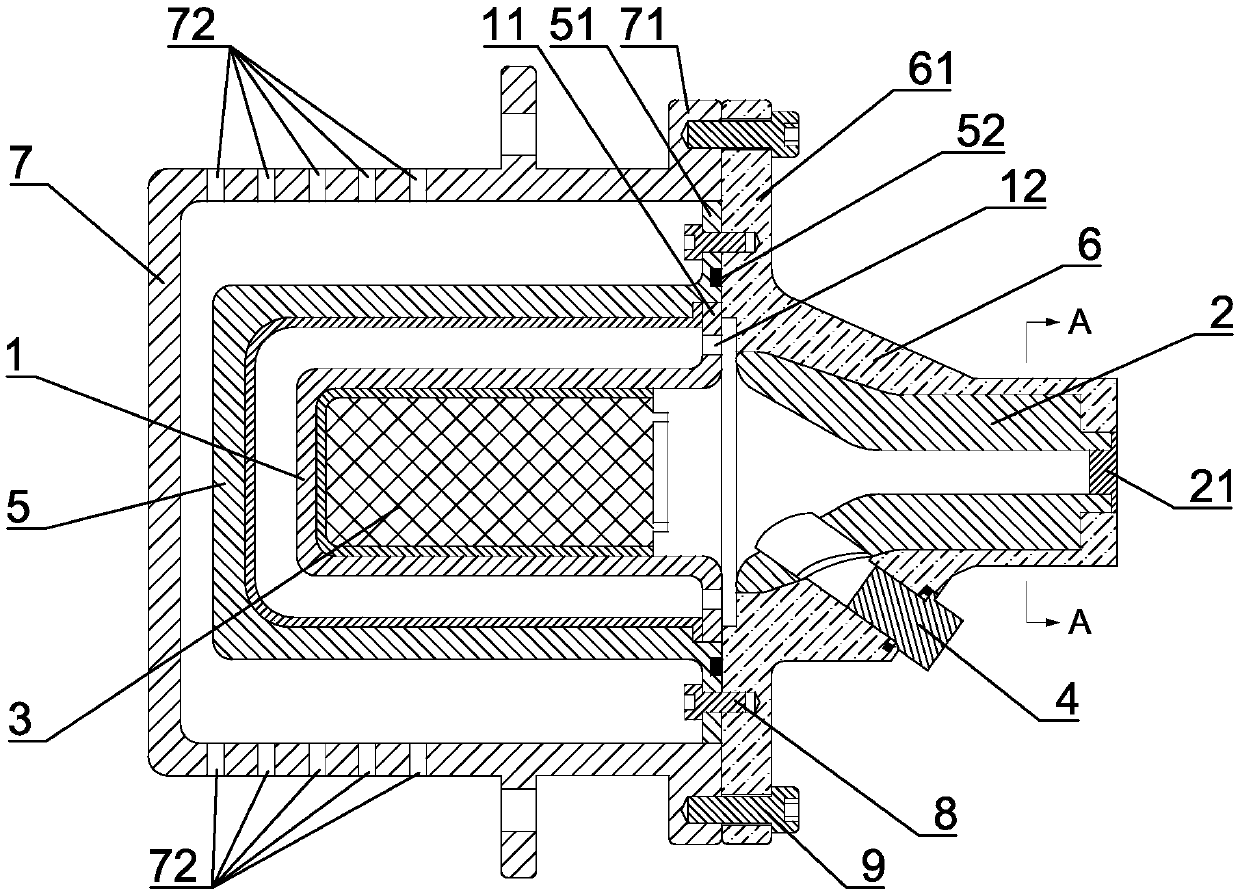

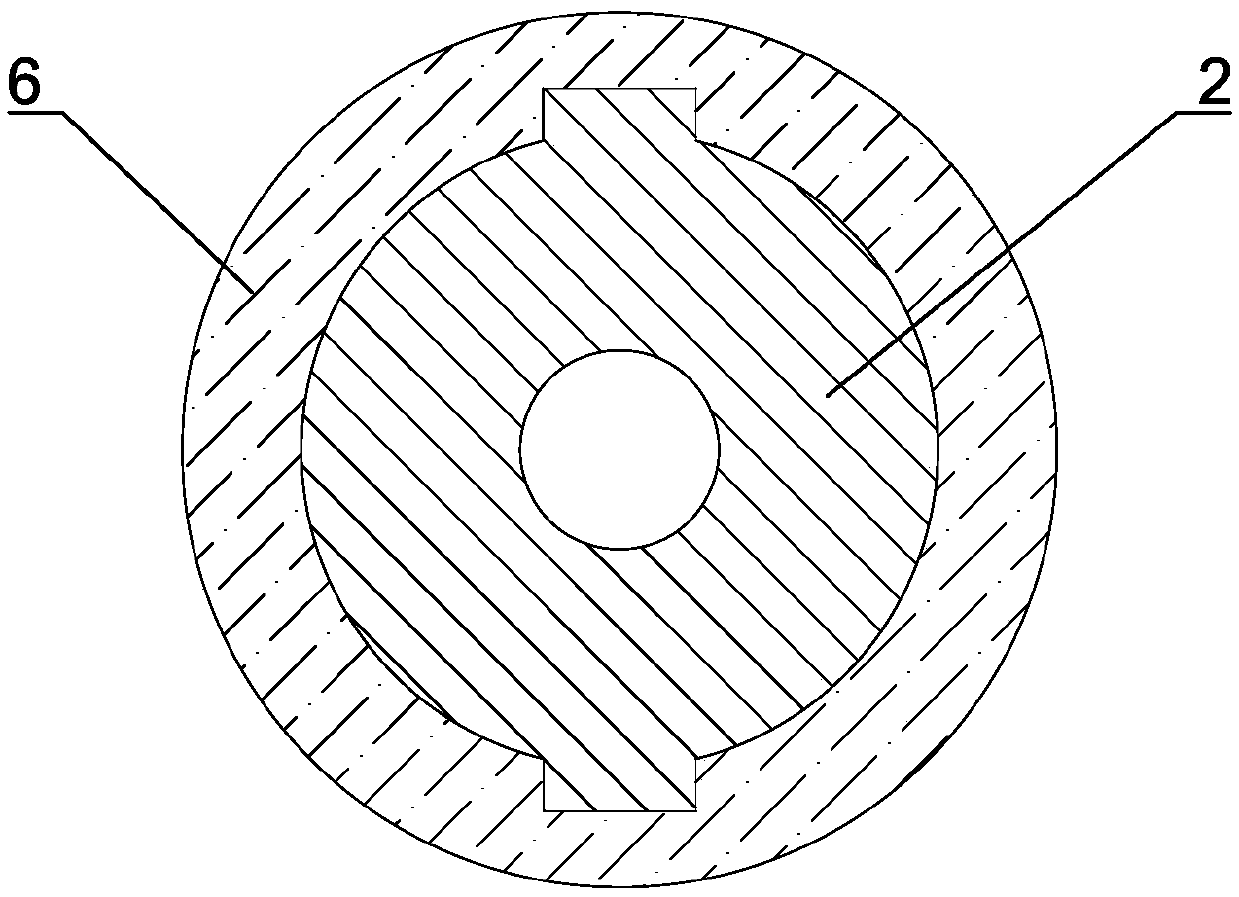

[0018] like figure 1 and figure 2 Shown is a specific implementation of a metal-based ignition power device of the present invention, which includes a barrel-shaped inner casing 1 with an opening facing the right and a nozzle 2 coaxially arranged at the right port of the inner casing 1 . A propellant grain 3 is arranged in the inner casing 1, an electric igniter 4 facing the propellant grain 3 is arranged on the nozzle 2, and the propellant grain 3 adopts a metal matrix composite solid propellant grain. A barrel-shaped outer shell 5 with an opening facing the right and a nozzle seat 6 that is sleeved on the nozzle 2 are also provided, so that the outer shell 5 is coaxially sleeved on the outside of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com