Shaping and forming equipment for cavity material pipe

A technology of tube shaping and cavity, which is applied in the field of cavity material tube shaping and forming equipment, can solve the problems of strict material use range, restrictive use conditions, and difficulty in realizing general processing of various materials, so as to improve the forming efficiency and The effect of quality, simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

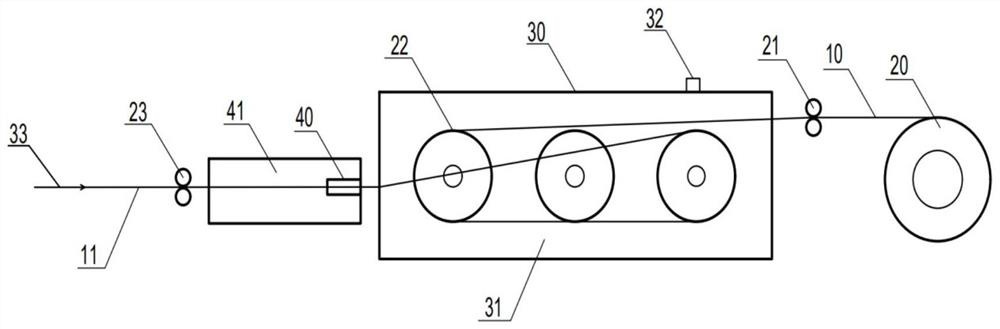

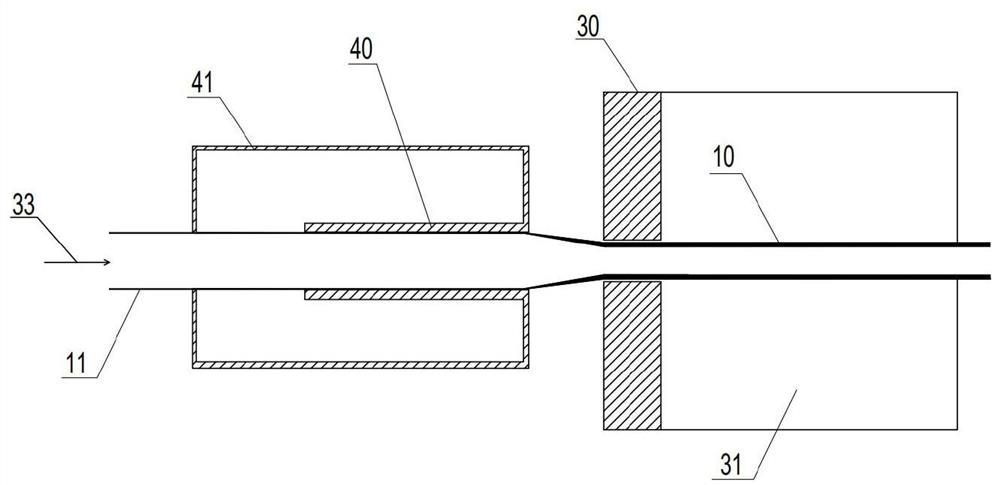

[0041] This embodiment 1 provides a cavity material tube shaping equipment, including a heating system, a shaping system, a pressure control system and a delivery system; the heating system includes a heating cavity 30 and a heating medium 31, and the heating medium 31 is located in the heating cavity Inside the body 30, it is used to heat the material to be shaped to a softening or deformable temperature; the shaping system is located at the rear end of the heating cavity 30, and includes a shaping cavity 40 and a cooling system to realize shaping and cooling of the material; the pressure control The system includes a material internal pressure control system 33 for controlling the shaping force of the shaping material and a heating cavity pressure control system; the conveying system includes a material conveying mechanism and a material detachment machine, used to convey the material through the heating system and the cooling and shaping system, so that Material can be conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com