Environment-friendly tea leaf dryer

A kind of tea drying machine, environmental protection technology, applied in the direction of drying machine, tea drying, drying, etc., can solve the problems of not obvious improvement of drying efficiency, poor effect of stir-frying, more dust rising, etc., to achieve improved turnover The effect of stirring efficiency, reducing vibration and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

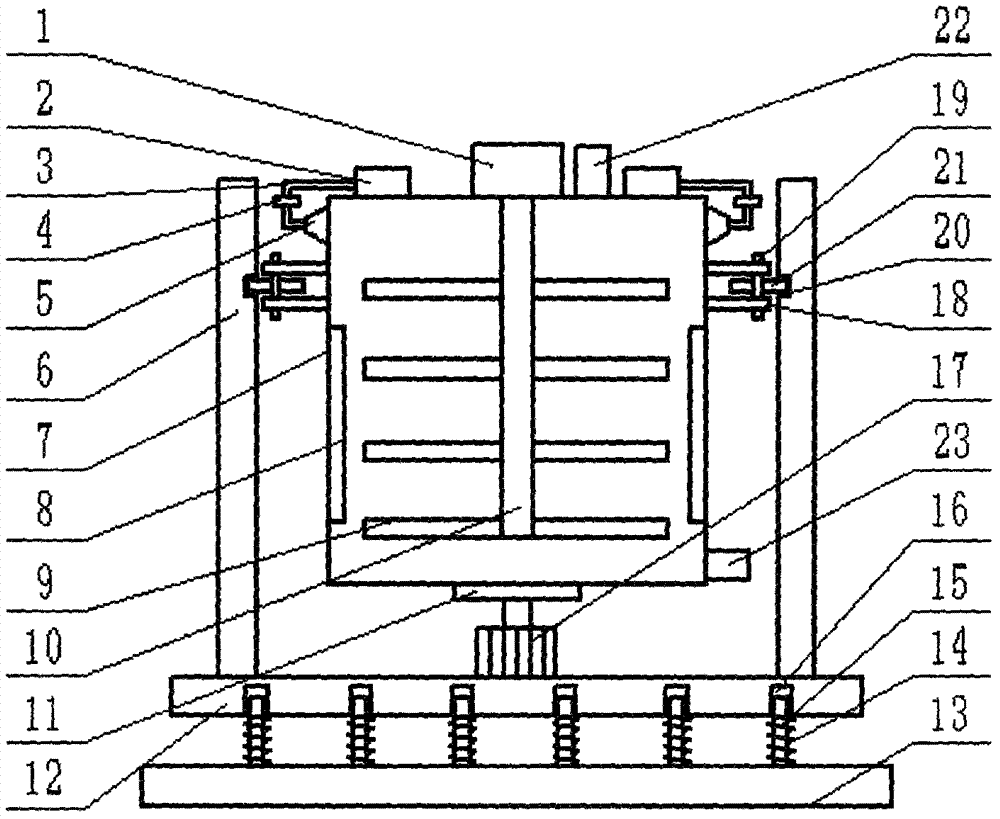

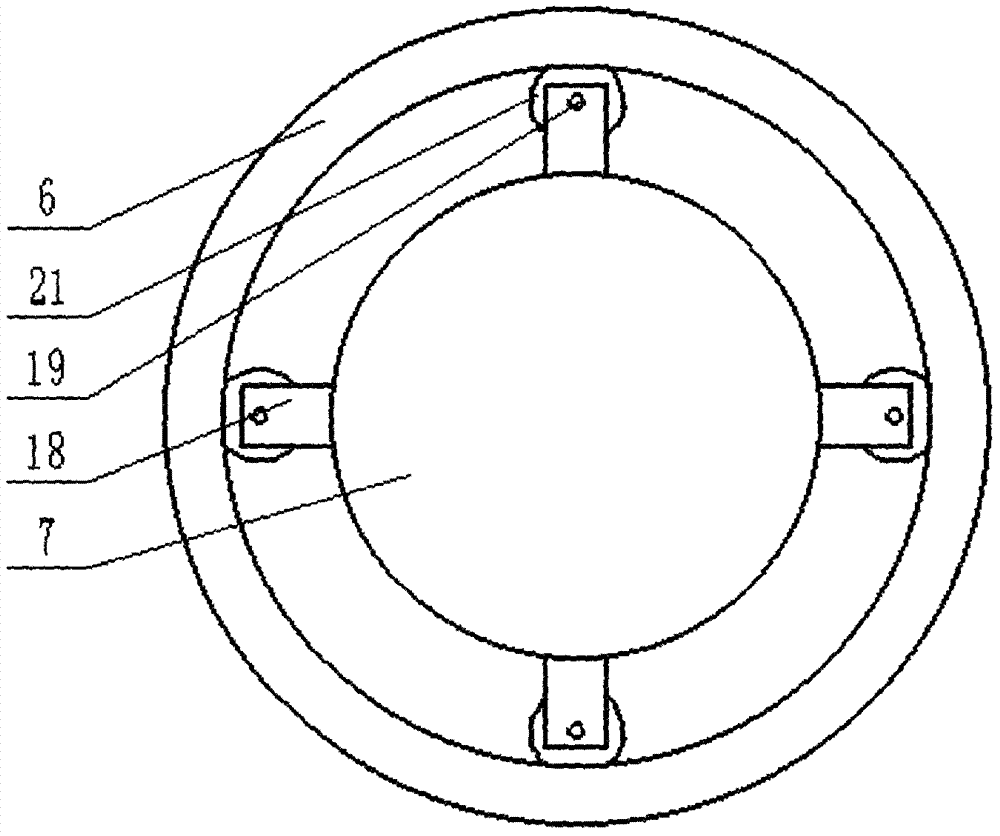

[0017] see Figure 1-2 , an environment-friendly tea dryer, comprising a drying cylinder 7, a bottom plate 12, an outer cylinder body 6 and a base 13, the upper end side of the drying cylinder 7 is connected with a feed pipe 22, and the bottom of the drying cylinder 7 One side of the end is connected with a discharge pipe 23, and a dust collection box 2 is installed on both sides of the top of the drying cylinder 7; The inside of the cylinder 7 is connected, and the dust collecting pipe 3 is provided with a dust collector 4; the middle part of the upper end of the drying cylinder 7 is fixedly installed with a motor 1, and the output shaft of the motor 1 is connected with a rotating shaft 10, and a stirring shaft is welded on the rotating shaft 10. Blade 9, the both sides of stirring blade 9 are fixedly installed with heating tube 8 on the inner si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com