Air drying device for tea leaf processing

An air-drying device and tea technology, which are applied in tea drying, drying gas arrangement, drying, etc., can solve the problems of increasing tea air-drying cost, long tea air-drying time, and high labor intensity, and achieve simple structure, low cost, and high efficiency. The effect of drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

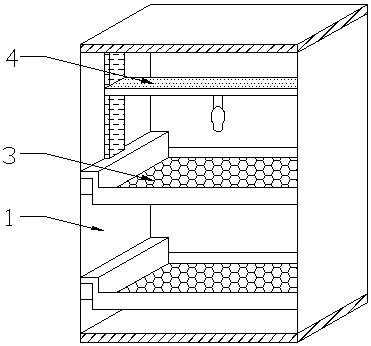

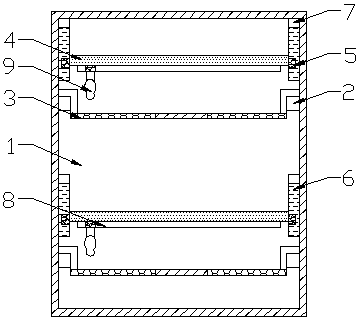

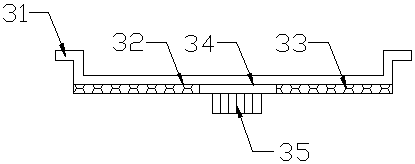

[0018] Such as Figure 1-3 As shown, an air-drying device for tea processing includes an air-drying chamber 1, a tea air-drying tray 3 and a hot air blower 9, and a plurality of racks 2 are installed on opposite sides of the inside of the air-drying chamber 1. A tea air-drying tray 3 is installed, and the tea leaf air-drying tray 3 includes a tray fixing frame 31 and a tray bottom plate 32 installed on the placement frame 2, and a horizontal plate 4 is installed in the air-drying chamber 1 on the top of the tea leaf air-drying tray 3, and the The two ends of the horizontal plate 4 are slidingly connected with the side guide rails 6 on both sides of the air-drying chamber 1 through the slide seat 5. The top of the side guide rail 6 is equipped with a cylinder 7, and the cylinder 7 is connected with the slide seat 5 through a piston rod. The bottom of the horizontal plate 4 is equipped with a horizontal guide rail 8, and a hot air blower 9 is slidably installed on the horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com