Drying device for tea processing

A drying device and tea technology, which is applied in the direction of tea drying, drying, drying machine, etc., can solve the problems of uneven contact between tea and hot air, poor drying effect, etc., and achieve improved drying efficiency, uniform heating, and contact full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

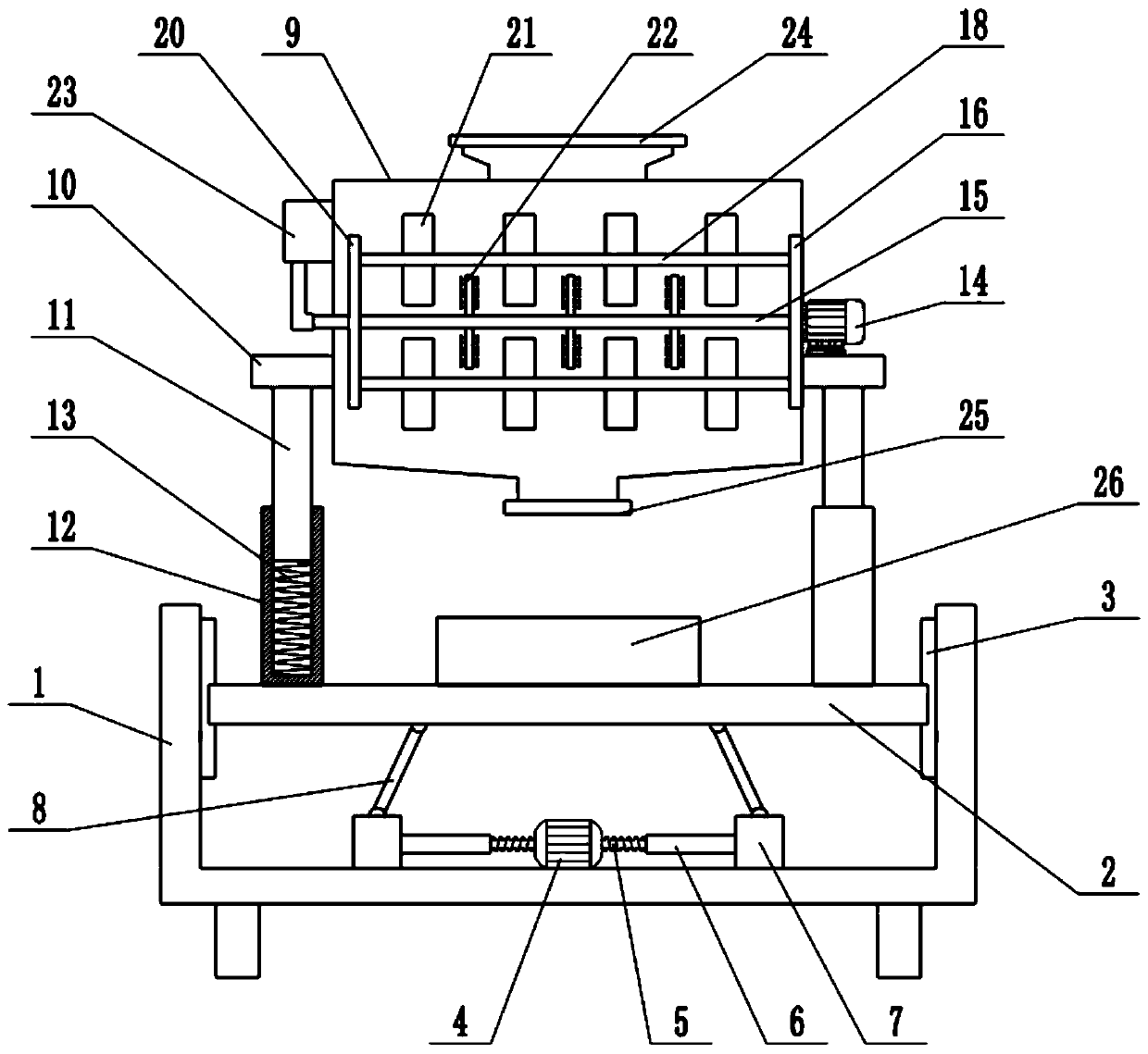

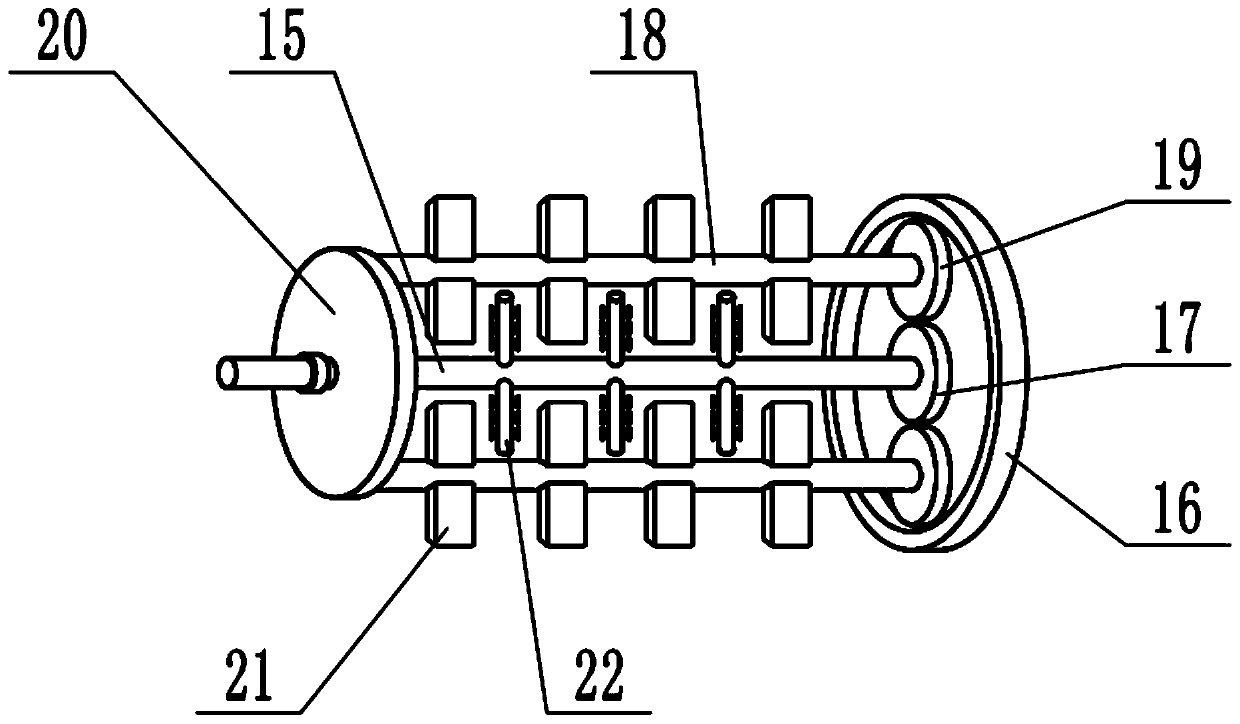

[0022] See Figure 1-3 In the embodiment of the present invention, a drying device for tea processing includes a base 1, a lifting plate 2, a drying cylinder 9 and a hot air blower 23. A lifting plate 2 is installed inside the base 1, and the base 1 Guide rails 3 are installed on the inner side wall of the lifting plate 2. Both ends of the lifting plate 2 are embedded in the guide rail 3. The lifting plate 2 can slide up and down along the guide rail 3. A drying cylinder 9 is provided above the lifting plate 2. The left and right sides of the drying cylinder 9 The sides are respectively fixedly connected with a fixed plate 10, the lower surface of the fixed plate 10 is fixedly connected with a support rod 11, the lower end of the support rod 11 is sleeved with a guide tube 12, the support rod 11 is slidably connected to the guide tube 12, and the inside of the guide tube 12 is installed There is a spring 13, and the lower end of the guide cylinder 12 is fixedly connected with t...

Embodiment 2

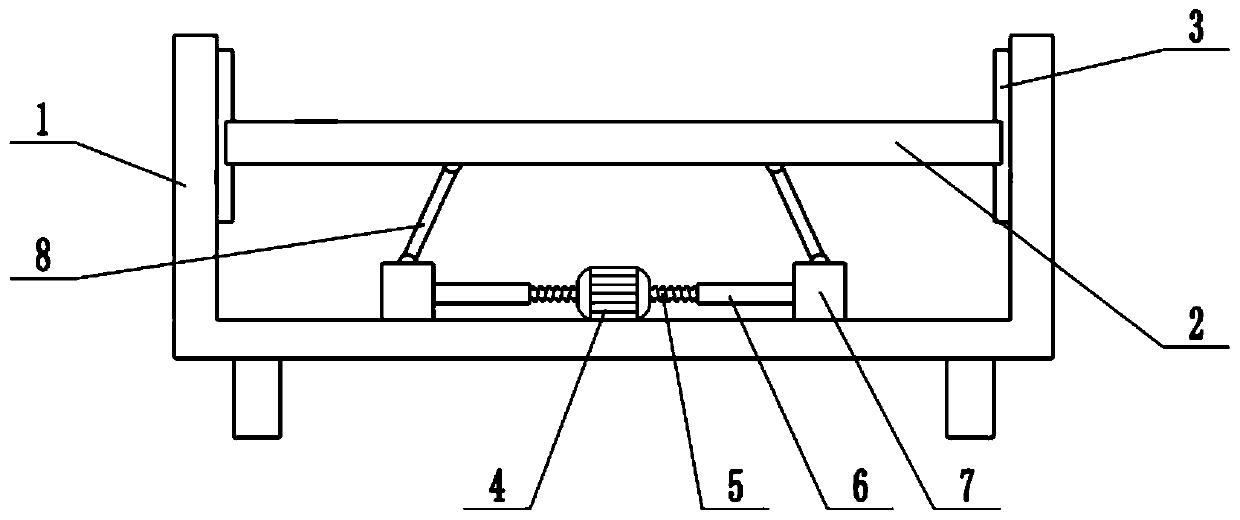

[0024] On the basis of embodiment 1, the bottom of the base 1 is fixedly connected with a dual-axis motor 4, the dual-axis motor 4 is a forward and reverse motor, and the two shaft extension ends of the dual-axis motor 4 are respectively installed with a screw rod 5, a screw rod 5 is sleeved with a sleeve 6, the screw rod 5 is threadedly connected with the sleeve 6, the end of the sleeve 6 is fixedly connected with a slider 7, the slider 7 is slidingly connected with the bottom of the base 1, and the upper surface of the slider 7 It is hinged with a connecting rod 8. The top end of the connecting rod 8 is hinged with the lifting plate 2 to control the forward and reverse rotation of the biaxial motor 4, which can drive the screw rod 5 to forward and reverse, thereby driving the slider 7 to move left and right, and then the connecting rod 8 drives the lifting The plate 2 vibrates up and down, so that the tea leaves are tossed up and down in the drying cylinder 9, so that the tea ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com