Chrysanthemum central heating negative-pressure drying killout system

A central heating and negative pressure technology, applied in tea drying, drying solid materials, drying chamber/container, etc., can solve the problems of reducing the utilization value and efficiency of chrysanthemum, loss of beneficial ingredients, low energy utilization rate, etc., and achieve improvement The effect of drying quality, complete preservation and high heat utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

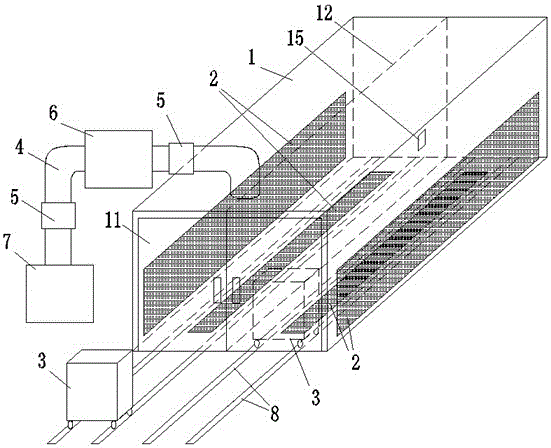

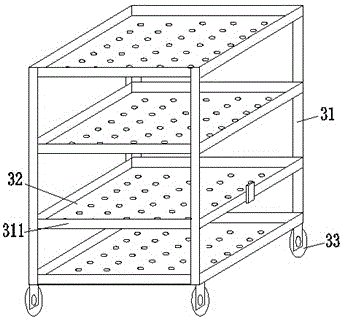

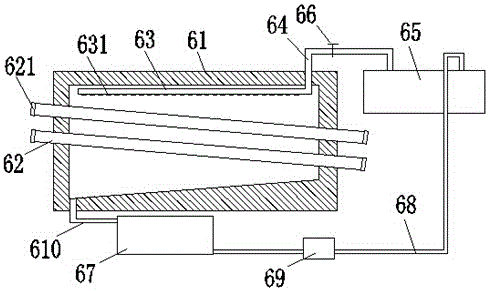

[0028] refer to Figure 1 to Figure 8 , the present embodiment provides a central heating negative pressure drying and cleaning system for chrysanthemums, comprising a drying chamber 1, the bottom of the drying chamber 1 and the side walls on both sides are provided with serpentine heating pipes 2, and the serpentine heating pipes 2 is a hot steam pipeline. There are multiple drying racks 3 arranged side by side in the drying chamber 1. A steam pipeline 4 is drawn from the drying chamber 1. An exhaust fan 5 and a condensing device 6 are arranged on the steam pipeline 4. The steam pipeline 4 is provided by the drying The upper end of the chamber 1 is led out, and a condensed water separation device 7 is also arranged at the downstream of the condensing device 6. An exhaust fan 5 is arranged between the condensing device 6 and the drying chamber 1 and between the condensing device 6 and the condensed water separating device 7. The serpentine heating pipes 2 arranged at the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com