Tea leaf drying and processing device

A processing device and tea technology, which are applied in the directions of tea drying, drying, drying machine, etc., can solve the problems such as the influence of finished product quality, low efficiency of tea drying device, lack of dregs removal, etc., and achieve the effect of prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

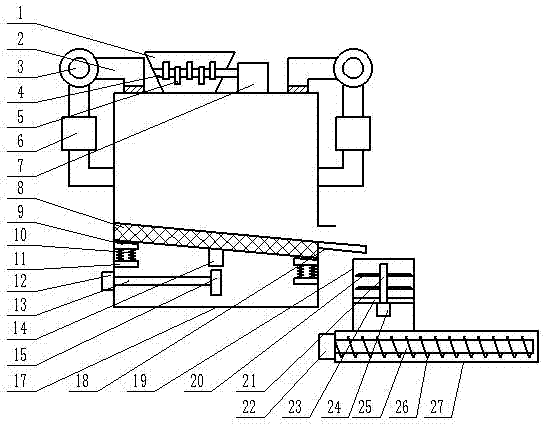

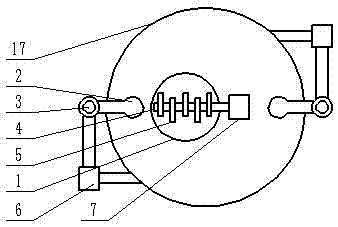

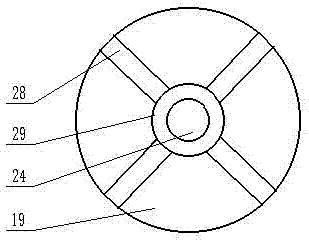

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

[0018] see Figure 1-3 , a tea drying and processing device, comprising a drying box 17, a crushing cylinder 19 and an extruding cylinder 27, the top of the drying box 17 is connected with a feeding hopper 1, and the horizontal rotation of the feeding hopper 1 is connected with a rotating shaft 4. A plurality of eccentric wheels 5 are welded on the rotating shaft 4, and one end of the rotating shaft 4 passes through the feed hopper 1 and is connected to the output shaft of the rotating motor 7; the left and right sides of the drying box 17 are provided with air ducts 2, One end of the air duct 2 communicates with the top of the drying box 17, the other end of the air duct 2 communicates with the side wall of the drying box 17, and the air duct 2 is connected with a blower fan 3 and a heating box 6 from top to bottom; The interior of the drying box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com