Drying device used for green tea processing

A drying equipment, green tea technology, applied in lighting and heating equipment, drying, drying machines and other directions, can solve the problem of uneven heating of beef, and achieve the effect of reducing drying time, high efficiency and good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

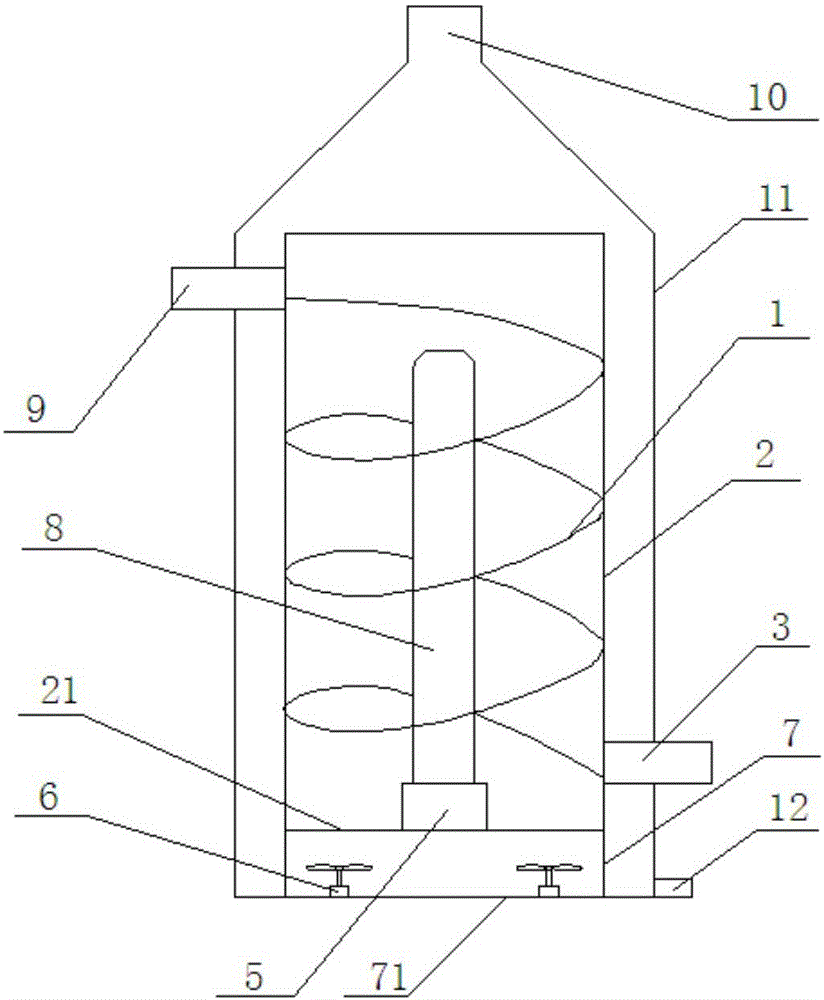

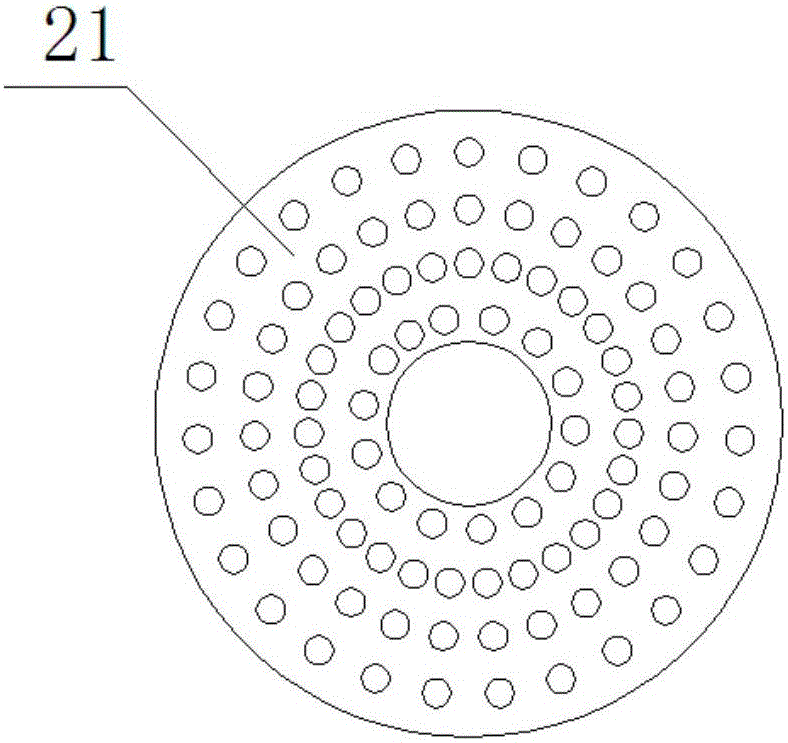

[0019] Such as figure 1 with figure 2 The shown drying equipment for green tea processing includes a spiral conveyor belt 1, a tower inner cylinder 2, a discharge port 3, a mounting seat 5, a base 7, a heating device 8, a feed inlet 9 and a tower outer cylinder 11; the inner cylinder 2 of the tower is fixedly installed on the base 7, and placed inside the outer cylinder 11 of the tower, the top of the outer cylinder 11 of the tower is provided with an exhaust port 10; the upper part of the inner cylinder 2 of the tower is provided with a feed port 9, the lower part is provided with a discharge port 3, and both the feed port 9 and the discharge port 3 extend to the outside of the outer cylinder 11 of the tower, and a spiral conveyor belt 1 is fixedly installed on the inner wall of the inner cylinder 2 of the tower, so that The up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com