Preparation of bisphenol A bis(diphenyl phosphoester )

A technology of diphenyl phosphate and phenol is applied in the field of preparation of bisphenol A, which can solve the problems of unstable purity of target product, impact on production environment, and difficulty in complete reaction, achieve good economic and social benefits, and reduce labor. Strength, the effect of avoiding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1, 80g (0.351mol) bisphenol A and 245g (1.596mol) phosphorus oxychloride are added to the four ports of dry, replaced with nitrogen and equipped with stirrer, thermometer, nitrogen inlet pipe, oil heating device In the flask, raise the temperature to 60°C and stir slowly until the bisphenol A is completely dissolved, as the dissolved material, keep warm for later use; weigh 1.5g of anhydrous aluminum trichloride and 100g (0.651mol) of phosphorus oxychloride In a four-necked flask equipped with a stirrer, reflux pipe, thermometer, nitrogen gas introduction pipe, heating device and hydrogen chloride absorption device, the temperature was raised rapidly to 90 °C, and then the above dissolved materials were slowly added dropwise, and added dropwise over 3 hours. Completed, then reacted for 2 hours under the condition of gradient temperature increase from 110°C to 130°C, then cooled the material to below 60°C under the condition of feeding a small amount of nitroge...

Embodiment 2

[0019] Embodiment 2, 80g (0.351mol) bisphenol A and 230g (1.503mol) phosphorus oxychloride are made into dissolved material; Weigh 1g anhydrous aluminum trichloride and 90g (0.586mol) phosphorus oxychloride in four ports Rapidly heat up to 70°C in the flask, then add the above-mentioned dissolved materials dropwise in the time of 2 hours, distill out excessive phosphorus oxychloride after the completion of the reaction, add 127g (1.351mol) phenol in the material that has been distilled. React for 8 hours under the condition of gradient temperature rise from 70°C to 150°C, and finally wash to obtain the target product. Other technical characteristics are the same as embodiment 1.

Embodiment 3

[0020] Embodiment 3, 80g (0.351mol) bisphenol A and 280g (1.824mol) phosphorus oxychloride are made into dissolved material; Weigh 2g anhydrous aluminum chloride and 150g (0.977mol) phosphorus oxychloride in four ports Rapidly heat up to 80°C in the flask, then add the above-mentioned dissolved materials dropwise in the time of 2 hours, distill out excessive phosphorus oxychloride after the completion of the reaction, add 136g (1.446mol) phenol in the material that has been distilled. React for 10 hours under the condition of gradient temperature rise from 70°C to 150°C, and finally wash to obtain the target product. Other technical characteristics are the same as embodiment 1.

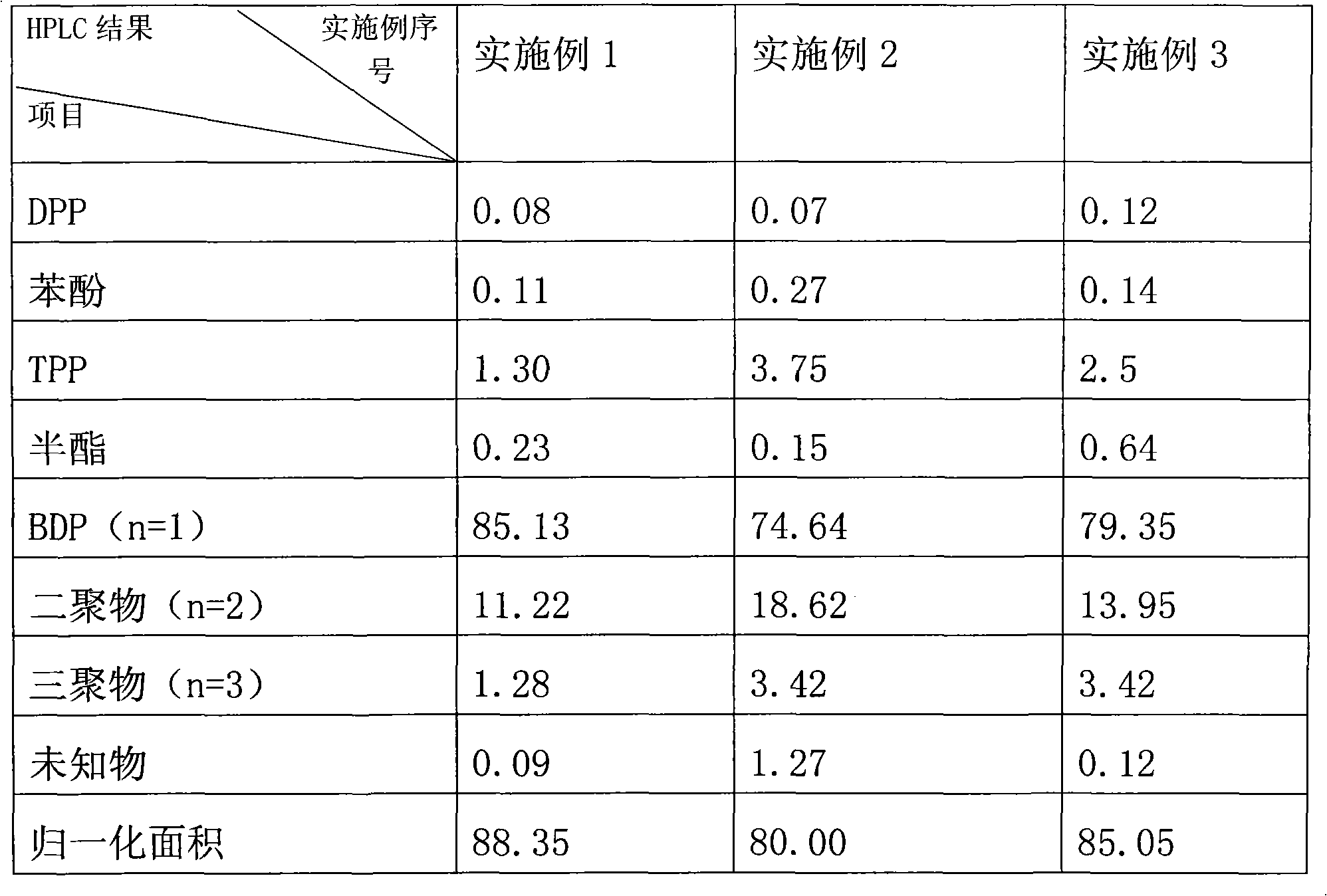

[0021] It is found through testing that the product prepared by using the preparation method of the present invention has stable quality and superior performance, and its normalized area is 4% higher than that of the product prepared by the existing method on average. The following table is the HPLC ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com