Multifunctional assembling and pouring type templated block, use method and use thereof

A pouring-type, multi-functional technology, applied in the direction of buildings, building components, building structures, etc., can solve the problems that the cross-sectional area of the pouring hole cannot be too large, does not have the function of thermal insulation and sound insulation, and the degree of standardization is low, so as to achieve improvement The effect of overall waterproof and anti-leakage performance, high-efficiency waterproof and anti-leakage performance, and unified quality standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

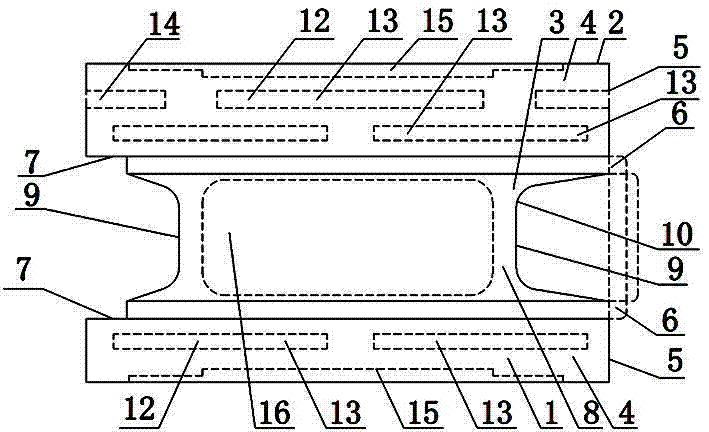

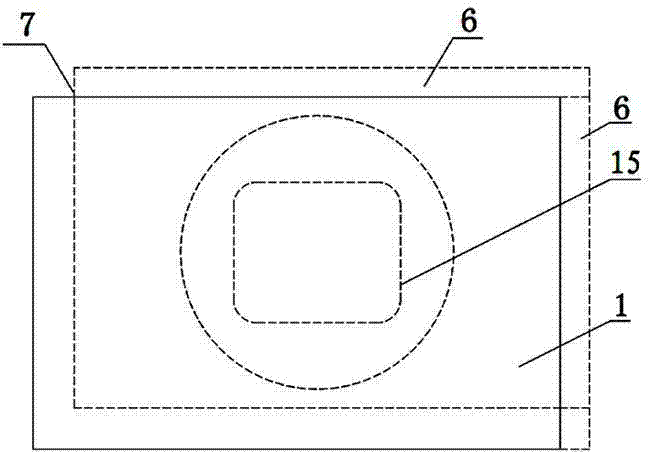

[0083] Such as Figure 4 As shown, the multi-functional assembled pouring formwork block includes two front panels 1 and rear panels 2 parallel to the wall, and the front panel 1 and the rear panel 2 are connected by an intermediate panel 3 arranged between the two panels. The right surface A5 of the front panel 1 and the rear panel 2 is respectively provided with a convex rib 6 extending vertically, and the left surface A of the front panel 1 and the rear panel 2 is respectively provided with a notch 7; and the notch 7 corresponds to the convex rib 6 Setting; the lower surface B and the left surface B of the middle plate 3 are respectively provided with a whole-body groove 9 , and the upper surface B8 and the right surface B10 of the middle plate 3 are set as a whole-body groove 9 .

[0084] Such as Figure 10 As shown, the multi-functional assembled pouring formwork block includes two front panels 1 and rear panels 2 parallel to the wall, and the front panel 1 and the rear ...

Embodiment 2

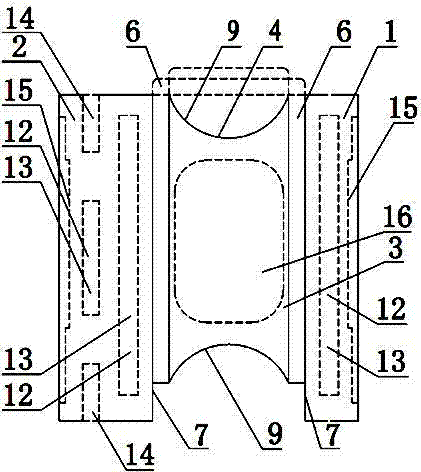

[0096] Such as Figure 5 As shown, the multi-functional assembled pouring formwork block includes two front panels 1 and rear panels 2 parallel to the wall, and the front panel 1 and the rear panel 2 are connected by an intermediate panel 3 arranged between the two panels. The upper surfaces A4 of the front panel 1 and the rear panel 2 are each provided with a horizontally extending convex rib 6, and the lower surfaces of the front panel 1 and the rear panel 2 are respectively provided with a notch 7; A5 is respectively provided with a convex rib 6 extending vertically, and the left surface of the front panel 1 and the rear panel 2 is respectively provided with a notch 7; and the notch 7 is provided correspondingly to the convex rib 6; The whole body grooves 9 are respectively provided, and the upper surface B8 and the right surface B10 of the middle plate 3 are set as the whole body grooves 9 . The back panel 2 is provided with a thermal insulation and sound insulation hole ...

Embodiment 3

[0107] Such as Figure 6 As shown, the multi-functional assembled pouring formwork block includes two front panels 1 and rear panels 2 parallel to the wall, and the front panel 1 and the rear panel 2 are connected by an intermediate panel 3 arranged between the two panels. The upper surfaces A4 of the front panel 1 and the rear panel 2 are each provided with a horizontally extending convex rib 6, and the lower surfaces of the front panel 1 and the rear panel 2 are respectively provided with a notch 7; A5 is respectively provided with a convex rib 6 extending vertically, and the left surface of the front panel 1 and the rear panel 2 is respectively provided with a notch 7; and the notch 7 is provided correspondingly to the convex rib 6; The whole body grooves 9 are respectively provided, and the upper surface B8 and the right surface B10 of the middle plate 3 are set as the whole body grooves 9 . The front panel 1 and the rear panel 2 are provided with thermal insulation and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com