Connection joint and connection structure of light-weight wallboard frame

A technology of lightweight wall panels and connecting joints, used in building components, building structures, buildings, etc., can solve the problems of frame joints that cannot be directly connected, inconvenient for storage and transportation, affecting assembly speed, etc., and achieves low labor intensity for workers. , saving logistics costs, in addition to the effect of low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

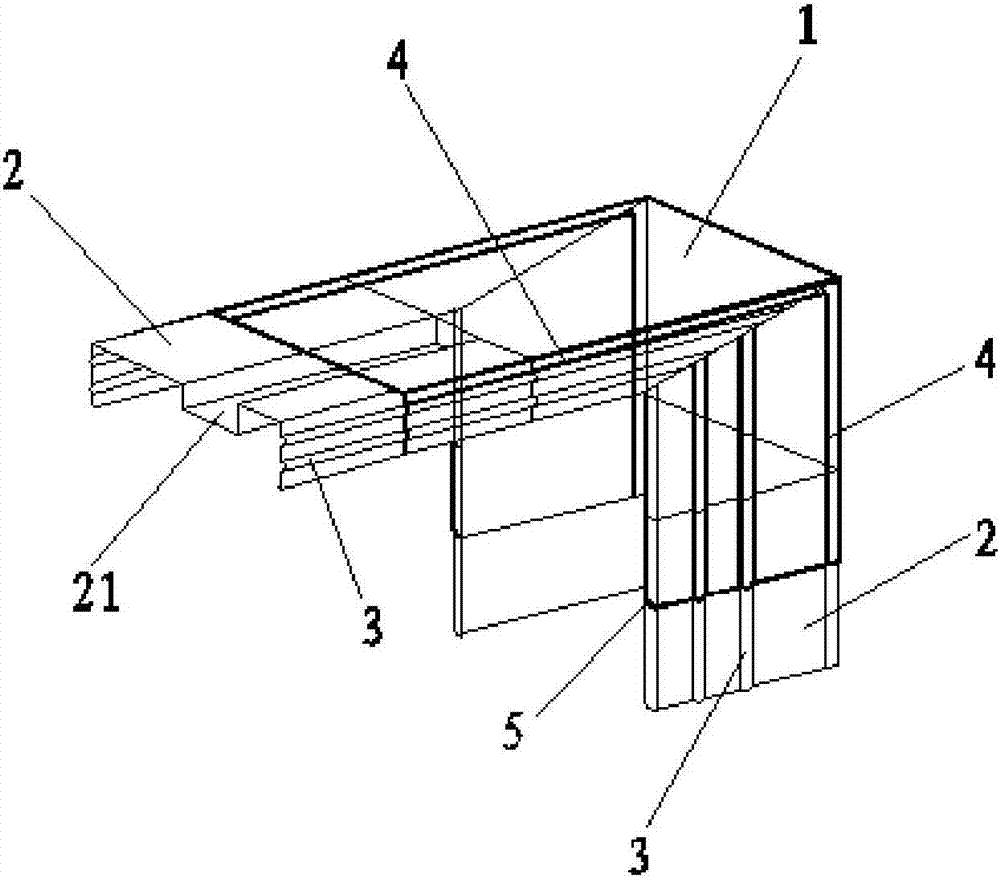

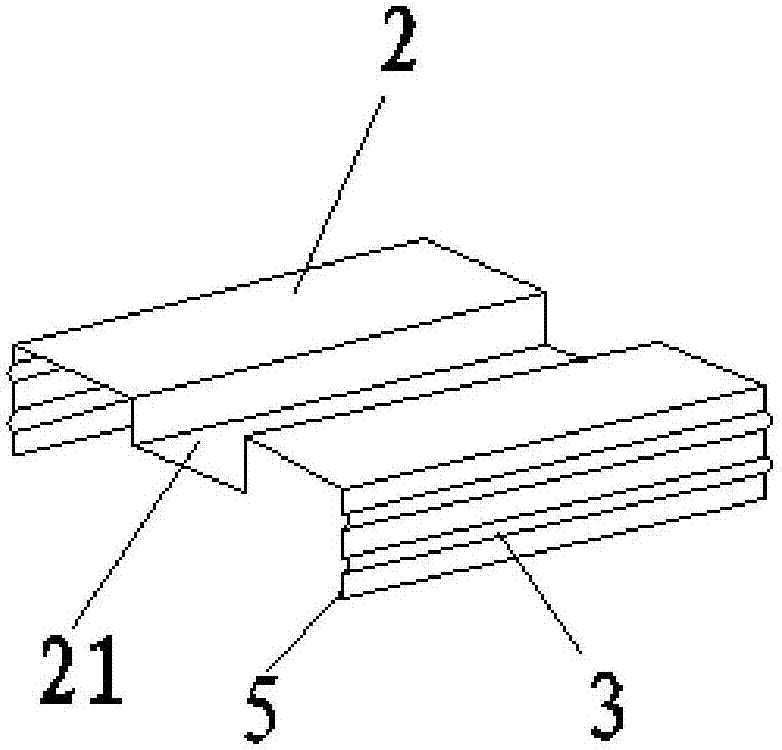

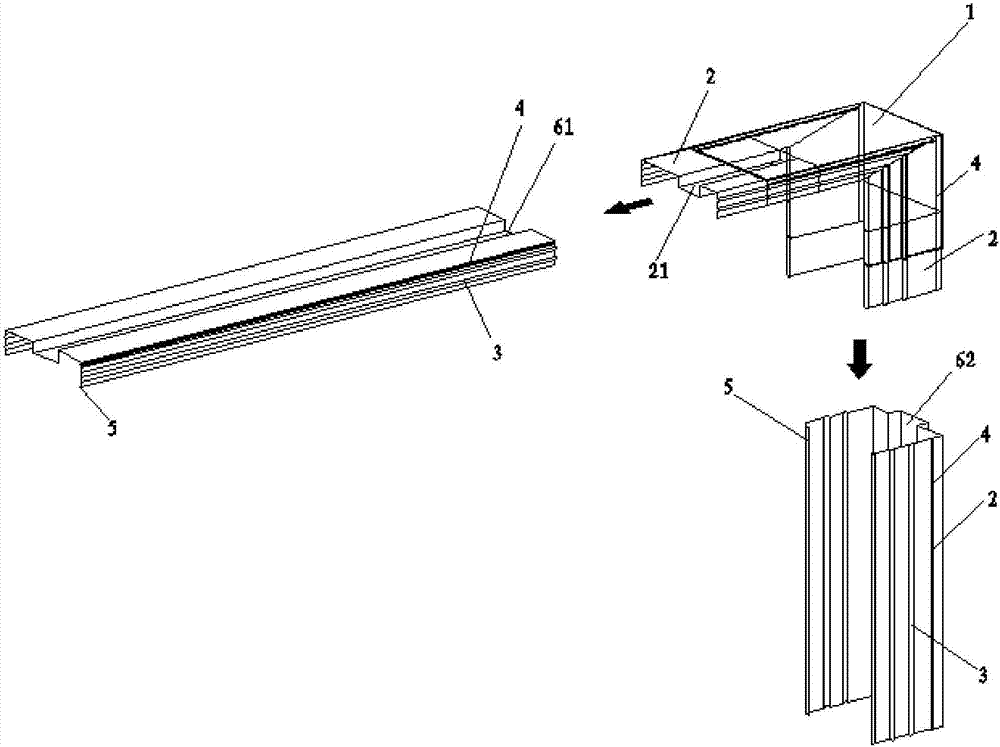

[0025] Such as figure 1 , figure 2 and image 3 As shown, a connection joint of a lightweight wallboard frame includes an outer wrapping angle 1 and a plug joint 2. The outer wrapping angle 1 is a groove-shaped profile including a top surface and two sides. The outer wrapping angle 1 in this embodiment is a right angle Shape, the plug connector 2 and the outer corner 1 are fixed on both ends of the outer corner 1, a part of the plug connector 2 is located in the notch of the outer corner 1, and the other part protrudes from the outer corner 1. The plug joint 2 is a groove-shaped profile including the top surface and two sides. The slots of the plug joint 2 and the outer corner 1 are in the same direction. Groove 21, said protruding line or groove 21 is provided at least on the top surface section of the plug joint 2 protruding from the outer corner 1, and the two sides of the plug joint 2 are provided with reinforcing ribs 3. The plug connector 2 is set in a groove shape w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com