Complete injection molding equipment and automatic injection molding production method thereof

A complete set of equipment, injection molding technology, applied in the direction of sorting, etc., can solve the problems of non-standard visual inspection, unstable manual installation, high risk, etc., and achieve the effect of reducing labor intensity, stable installation position, and high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

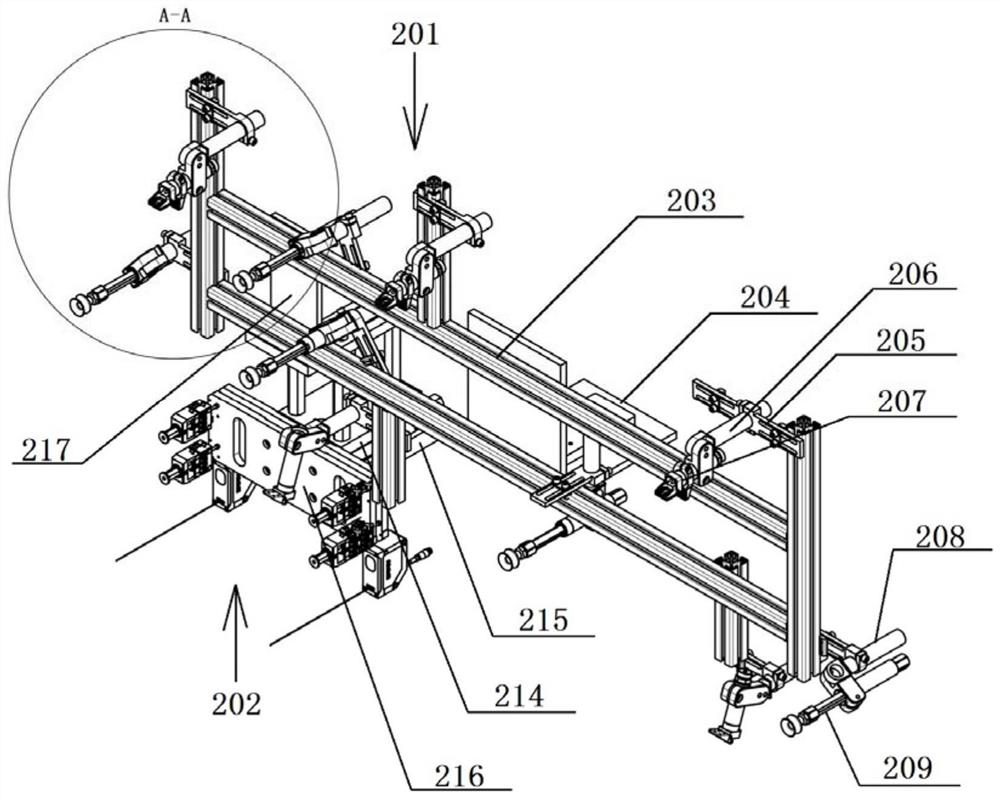

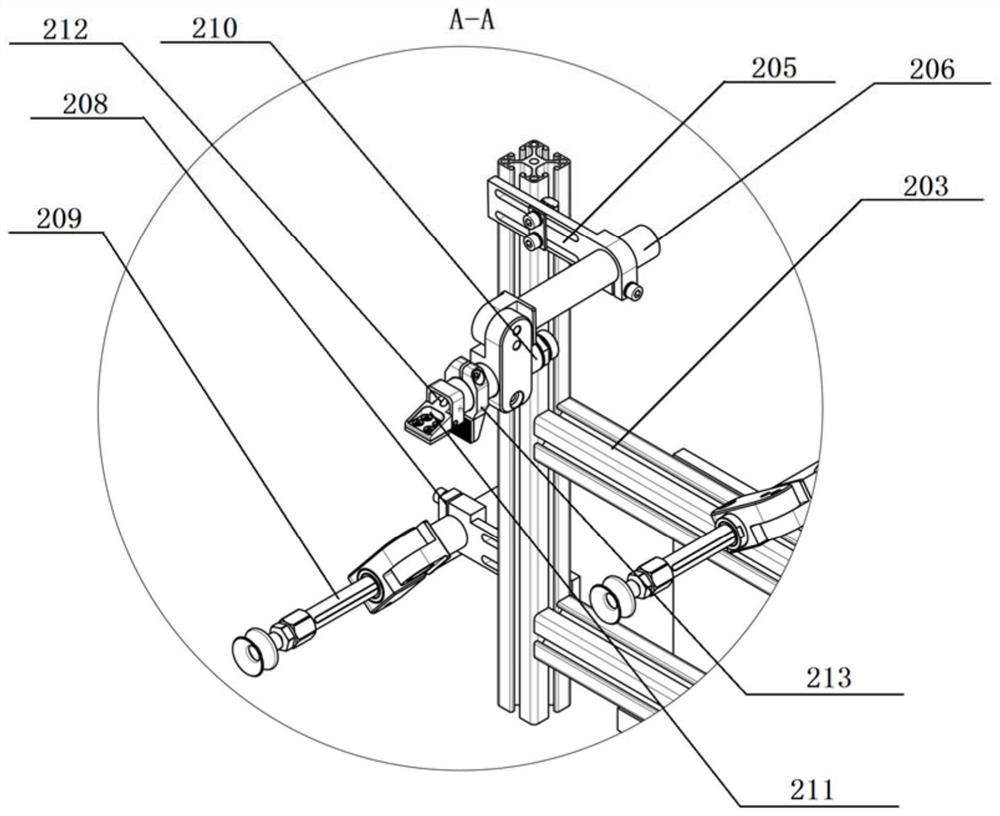

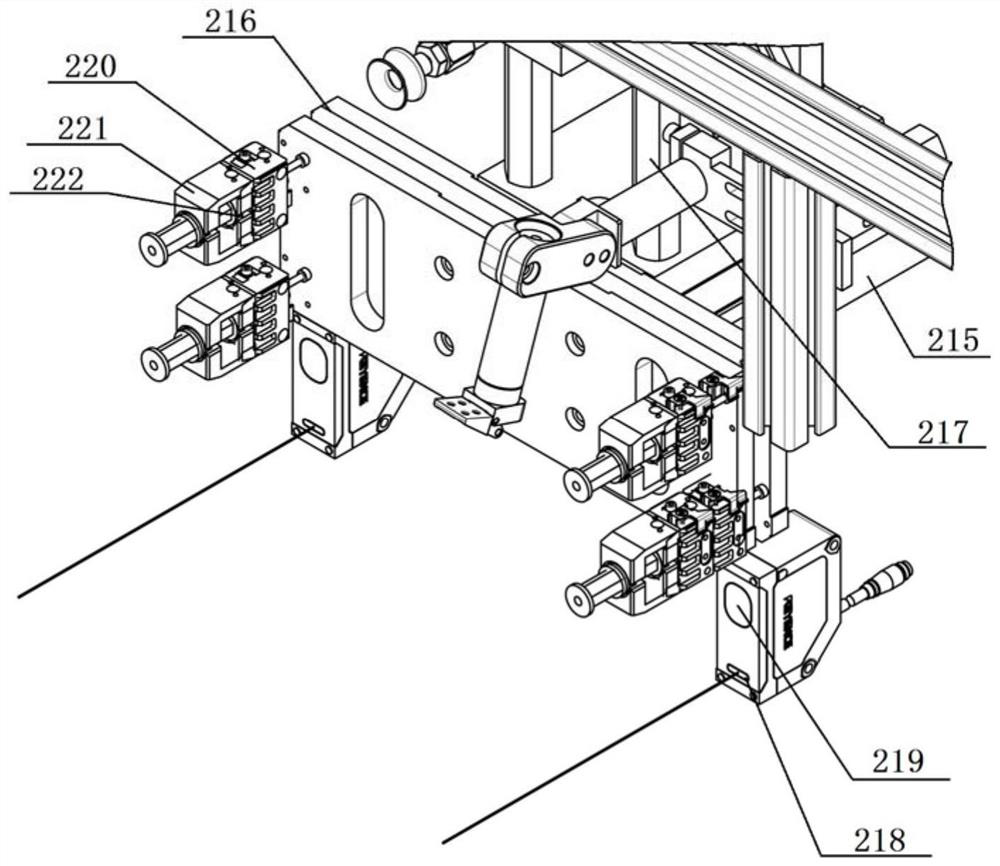

Embodiment 1

[0038] The complete set of injection molding equipment provided by this embodiment includes: a screw slide table mechanism 1, a screw gripper and a workpiece transfer mechanism 2, and a finished part conveying mechanism 3; the screw gripper and workpiece transfer mechanism 2 are used for grasping the screws and Inlaid into the specified position of the mold, and take out the instrument panel after injection molding; the screw gripper and workpiece transfer mechanism 2 include: a manipulator, a workpiece transfer mechanism 201 installed on the manipulator, and a screw gripper mechanism 202, the manipulator It is used to drive the workpiece transfer mechanism 201 and the screw gripper mechanism 202 to move between the injection film and the screw slide mechanism 2, and the screw gripper mechanism 202 is used to grab the four inlaid screws on the screw slide mechanism 2 and embed them. To the specified position of the mold, the workpiece transfer mechanism 201 is used to take out ...

Embodiment 2

[0044] The present embodiment provides an automatic production method for injection molding, which specifically includes the following steps:

[0045] Step S1: Use the screw slide mechanism 1 to move a group of four screws to the grasping place of the screw gripper and the workpiece transfer mechanism 201, wherein the slide cylinder and slide cylinder of the screw slide mechanism 1 are activated to drive the slider to move. Slide the rail 105 to the initial position, manually place the four screws in the screw storage holes of the screw receiving base 103, start the slide cylinder again, and the slide cylinder drives the slide block with the screws to move to the screw gripper and workpiece transfer Where the mechanism 201 grabs, another screw slide mechanism arranged in parallel repeats the opposite movement to ensure the continuity of production;

[0046] Step S2: Use the screw gripper and the four screw fixing clips 221 of the screw gripper mechanism 202 in the workpiece tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com