Device and method for stabilizing air pressure in sealed molding chamber for 3D printing of metal

A 3D printing and stabilizing device technology, applied in the direction of electric fluid pressure control, additive manufacturing, energy efficiency improvement, etc., can solve problems such as air pressure instability, black smoke disorder, laser lens and molding chamber wall pollution, etc., to achieve technical The method is simple and easy to implement, guarantees safety and reliability, and improves the effect of stability and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

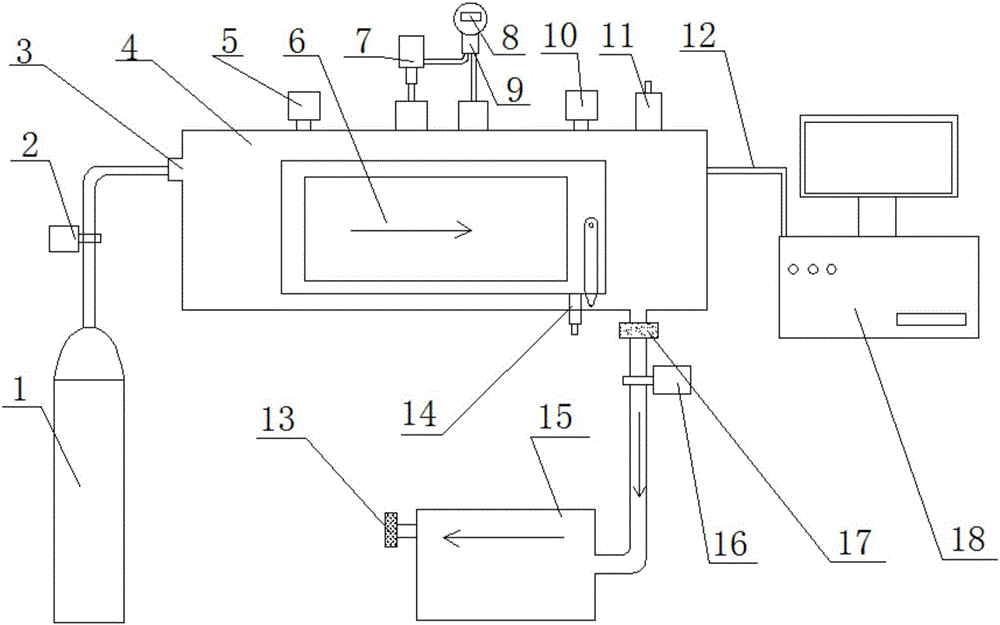

[0026] Such as figure 1 shown. The invention discloses an air pressure stabilization device in a metal 3D printing sealed molding chamber, comprising a molding chamber 4, a control device 18, an inert gas supply device for the molding chamber 4, an oxygen content detection device for detecting the oxygen content in the molding chamber 4, The vacuum device for the molding chamber 4, the pressure sensor device for detecting the air pressure in the molding chamber 4; the control device 18 is connected to the oxygen content detection device, the vacuum device and the pressure sensor device through the data line 12 respectively The inert gas supply device provides inert gas (such as nitrogen, argon, etc.) to the molding chamber 4, and then the gas in the molding chamber 4 is extracted by the vacuum pumping device and discharged, so that the gas in the molding chamber is circulated and purified.

[0027] Described inert gas supply device comprises inert gas source 1, and inert gas ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com