Treatment method of industrial waste water containing diazodinitrophenol

A technology of dinitrodiazophenol and industrial wastewater, which is applied in water/sewage treatment, natural water body treatment, neutralized water/sewage treatment, etc. It can solve problems such as difficulty in obtaining satisfactory results and difficulty in filtration and treatment, and achieve eradication Pollution and harm, low cost, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] best practice

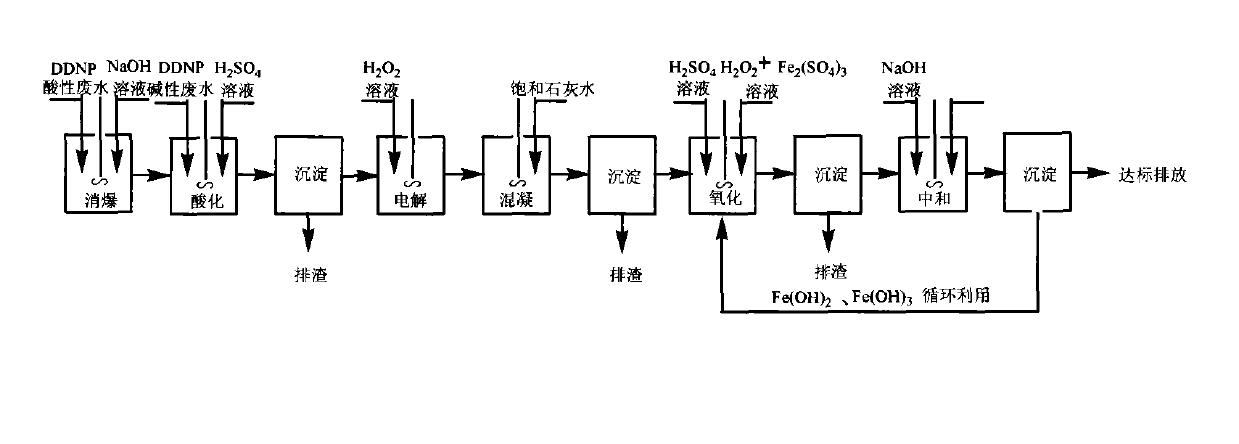

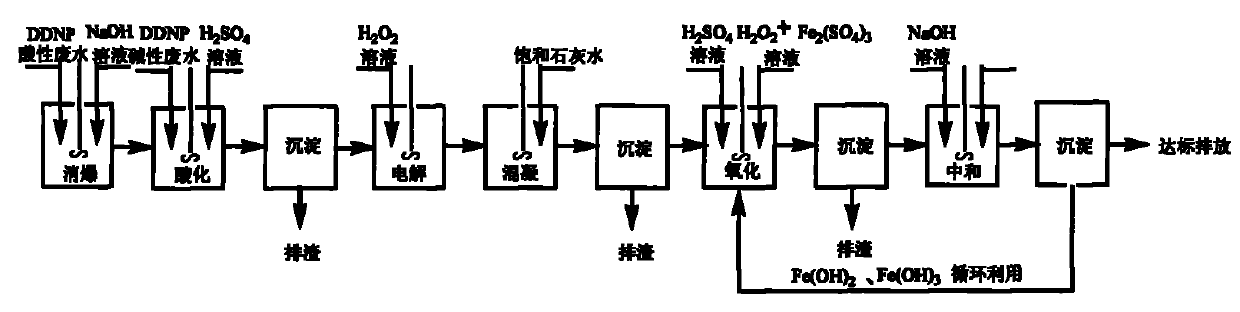

[0022] Send DDNP acidic wastewater (including washing wastewater and ground flushing wastewater) into the explosion-proof tank, and add sodium hydroxide solution until the pH value reaches 12.5 while stirring. After 3 hours of anti-explosion treatment, the acidic wastewater is sent to the sewage regulating tank and slowly mixed with the alkaline wastewater poured in advance. Adjust the acidity to pH 2.5 with sulfuric acid and filter. The separated waste water enters the electrolytic cell, and the concentration of 30% hydrogen peroxide solution is added in the cell, and the addition amount is by weight: m 废水 :m 过氧化氢 =1000:2.5, use graphite as the electrode, electrolyze for more than 4 hours under a DC power supply of about 10v. Send the electrolyzed wastewater to the coagulation tank, adjust the pH value to 8 with saturated lime water, coagulate for 2 hours, and filter. The filtered waste water flows into the oxidation pond, and the pH value of the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com