Method for zero discharge processing of waste saponification lye of cyclohexanone produced by cyclohexane oxidation technology

An oxidation process and cyclohexane technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. Emissions and other issues, to achieve significant environmental benefits, less energy consumption, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

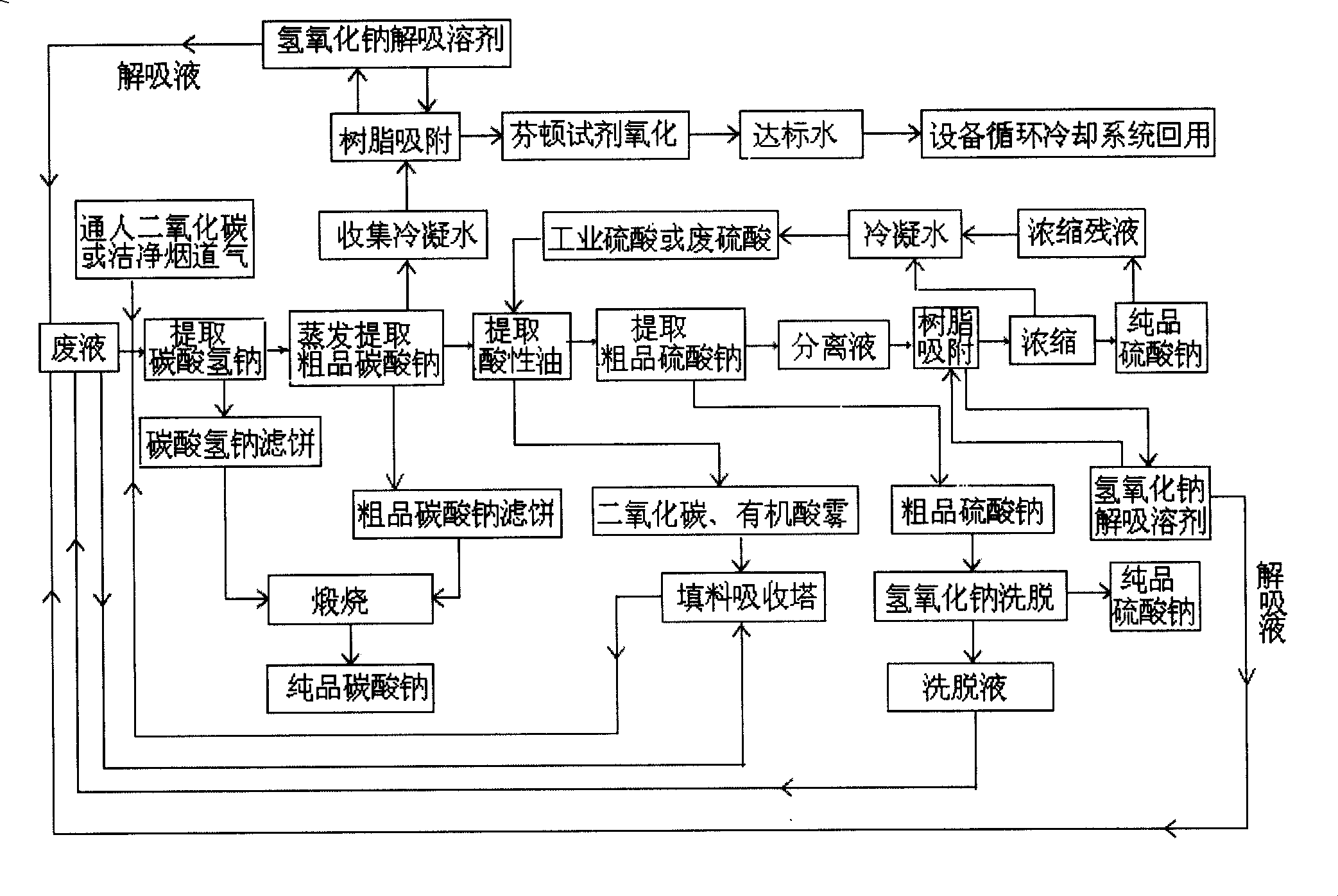

Image

Examples

Embodiment Construction

[0021] The basic material components and weight percentages of the saponification waste lye (hereinafter referred to as waste liquid) that the inventive method radically handles are:

[0022] Inorganic matter: sodium carbonate (Na 2 CO 3 ) about 7%

[0023] Sodium hydroxide (NaOH) about 8%

[0024] Organic matter: organic acids, alcohols, ketones, about 35%

[0025] The rest: about 50% water

[0026] Below in conjunction with technological process block diagram, briefly describe the implementation process of the inventive method:

[0027] (1) Feed a sufficient amount of carbon dioxide gas or clean flue gas into the waste liquid at normal temperature to extract sodium bicarbonate; the feed amount of carbon dioxide needs to meet the balance requirements of the following chemical reaction equation:

[0028] CO 2 +NaOH=NaHCO 3

[0029] CO 2 +Na 2 CO 3 +H 2 O=2NaHCO 3

[0030] This process is based on: Since the waste liquid contains about 15% of alkali substa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com