Method for fermentation production of hydroxyproline by adopting escherichia coli JL-HYP

A technology for Escherichia coli and hydroxyproline, which is applied in the field of producing hydroxyproline, and can solve the problems of affecting the refining yield and product quality, having many impurities in crude hydroxyproline, and being easily oxidized by hydroxyproline. , to achieve the effect of shortening the purity of the finished product, shortening the extraction cycle, and not easy to decompose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

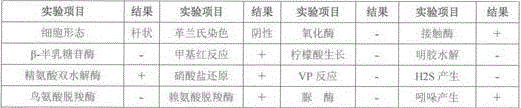

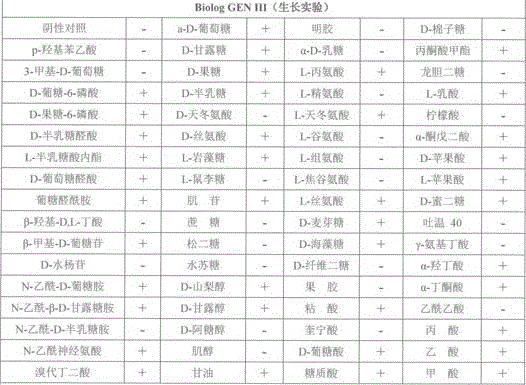

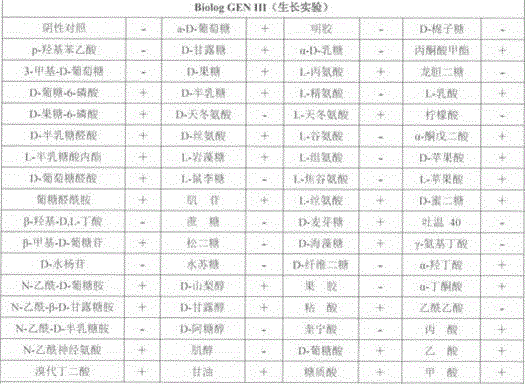

[0023] Escherichia coli JL-HYP and common hydroxyproline-producing Escherichia coli were inoculated on the slant, cultured in a biochemical incubator at 37°C for 20 hours, then diluted by gradient, spread on the complete medium (LB), and picked Take a single colony and inoculate it on the slant, and incubate at 30-36°C for about 12 hours in a biochemical incubator. Inoculate into a 500ml seed bottle, culture conditions: temperature 30-36°C, shaker speed 200rmp, culture time 6-8 h; when the OD value grows to about 1.0-2.0, inoculate into a 500ml fermentation bottle, inoculum size: 7 %, culture conditions: temperature 30-36°C, shaker speed 200rmp, fermentation cycle 30-45h. After the fermentation, the hydroxyproline content was detected to be 23.65g / L and 18.37g / L, and the yield increased by 28.74%.

Embodiment 2

[0025] Pick one ring of Escherichia coli JL-HYP and ordinary hydroxyproline-producing Escherichia coli from fresh slant and inoculate them into 500mL seed bottle, culture conditions: temperature 30-36℃, shaker speed 200rmp, culture The time is 6-8h; when the OD value grows to about 1.0-4.0, put the shake flask seeds into a 5L automatic fermenter with 3L fermentation medium at an inoculation amount of 10% for secondary seed cultivation. The culture temperature is 30-36°C, the tank pressure is 0.01-0.05MPa, the air flow rate is 1-8L / min and the stirring speed is 200-800r / min to maintain the dissolved oxygen at 10-50%, and the pH value is controlled between 7.0-7.2. The time is 5-8h. The secondary seeds were inserted into a 30L fully automatic fermenter with 18L fermentation medium at a 10% inoculum size for acidogenic fermentation. The fermentation temperature is 30-36°C, the tank pressure is 0.01-0.15MPa, the air flow rate is 5-50L / min and the stirring speed is 200-800r / min to...

Embodiment 3

[0027] Pick one ring of Escherichia coli JL-HYP and ordinary hydroxyproline-producing Escherichia coli from fresh slant and inoculate them into 500mL seed bottle, culture conditions: temperature 30-36℃, shaker speed 200rmp, culture The time is 6-8h; when the OD value grows to about 1.0-4.0, insert the shake flask seeds into a 0.6m 3 2m of fermentation medium 3Secondary seed cultures were carried out in fermenters. Cultivation temperature 30-36℃, tank pressure 0.01-0.05MPa, air flow 0.1-0.6m 3 / min and stirring speed 100-300r / min to maintain the dissolved oxygen at 10-50%, the pH value is controlled between 7.0-7.2, and the culture time is 5-8h. Insert the secondary seeds with 10% inoculum into the 6m 3 10m of fermentation medium 3 Acidogenic fermentation in fermenter. Fermentation temperature 30-36℃, tank pressure 0.01-0.15MPa, air flow 0.5-7 m 3 / min and stirring speed 200-800r / min to maintain the dissolved oxygen at 10-40%, the fermentation pH value is controlled betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com