Device and method for fully bonding touch screen with display screen

A display and touch screen technology, applied in chemical instruments and methods, lamination devices, lamination, etc., can solve the problems of low brightness, high light transmission loss, discounted display effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

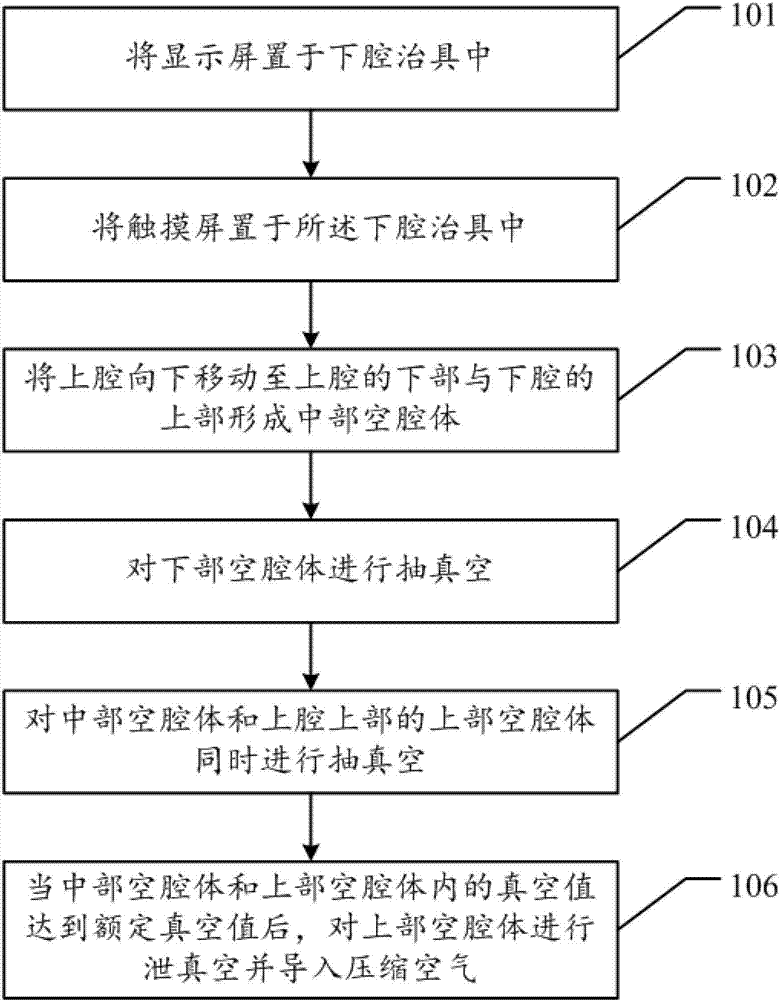

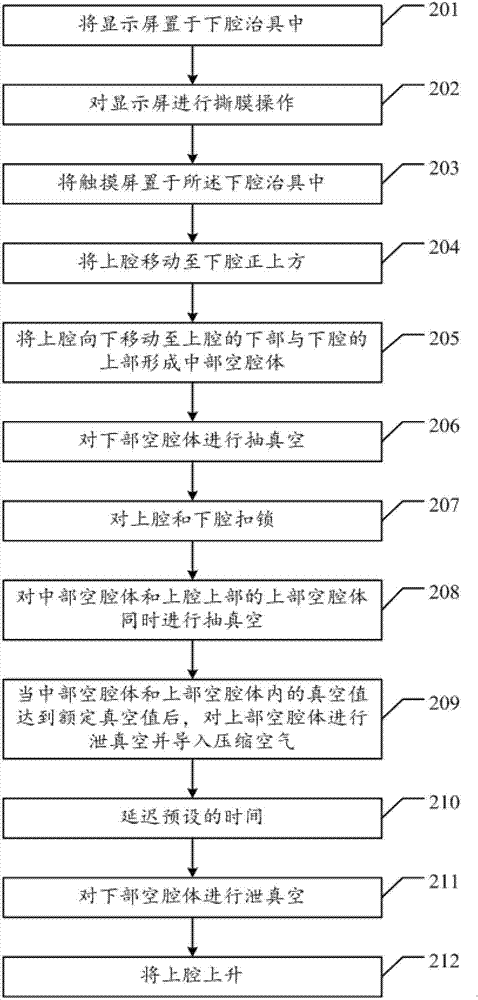

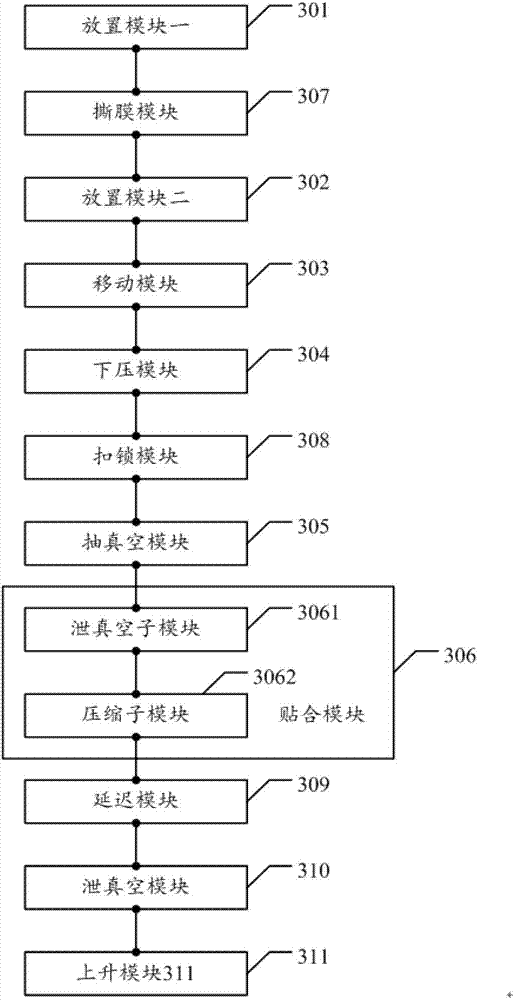

[0045] see figure 1 , the first embodiment of the method for fully laminating the touch screen and the display screen in the embodiment of the present invention includes:

[0046] 101. Place the display screen in the lower cavity fixture;

[0047] Before the full bonding of the touch screen and the display screen, the display screen is first placed in the lower chamber jig, and the bonding surface of the display screen is upward. The above-mentioned display screen, lower chamber jig and the lower part of the lower chamber form a lower cavity body.

[0048] 102. Place the touch screen in the lower chamber jig;

[0049] After the display screen is placed in the lower cavity jig, the touch screen can be placed in the lower cavity jig, and the bonding surface of the touch screen is downward.

[0050] 103. Move the upper cavity to just above the lower cavity;

[0051] After the touch screen is placed in the lower chamber, the upper chamber can be moved directly over the lower c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com