Electromagnetic induction rivet heater

A heating device and electromagnetic induction technology, applied in the direction of induction heating device, induction heating, etc., can solve the problems of inaccurate heating time and temperature control of the operator, affecting the strength and quality of riveting, oxidative decarburization of rivets, etc., to save raw materials, The economic and social benefits are obvious, and the effect of productivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

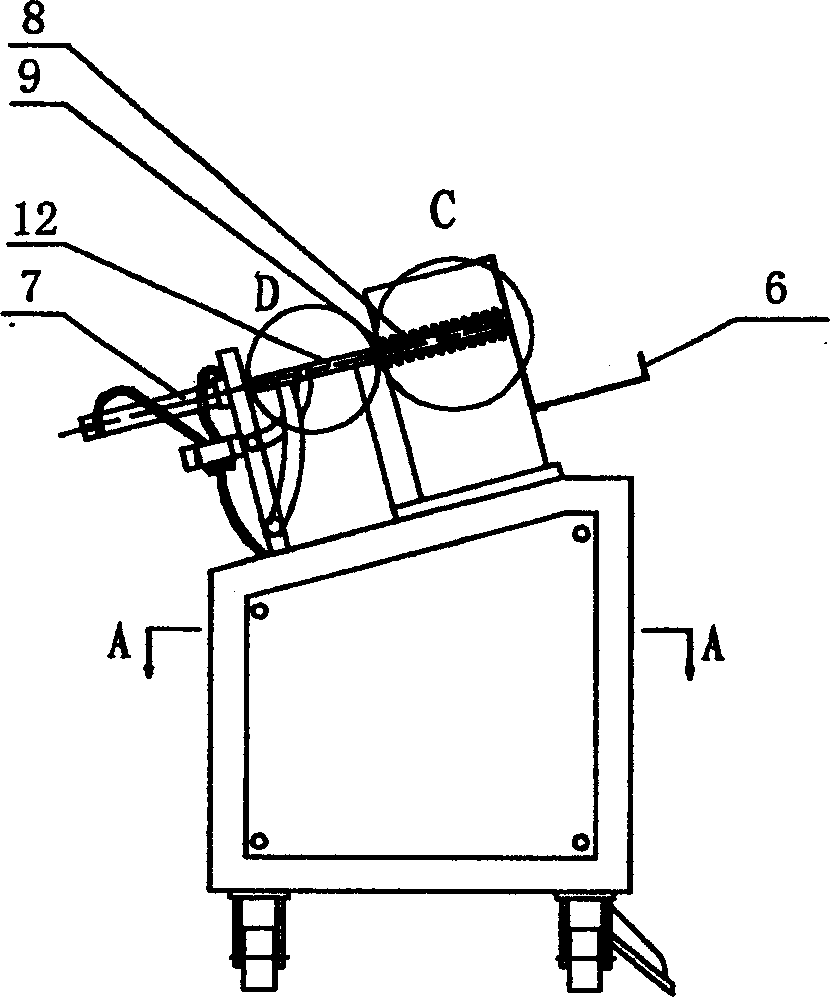

[0021] The specific content and working process of the present invention will be further described below with the embodiment shown in the accompanying drawings.

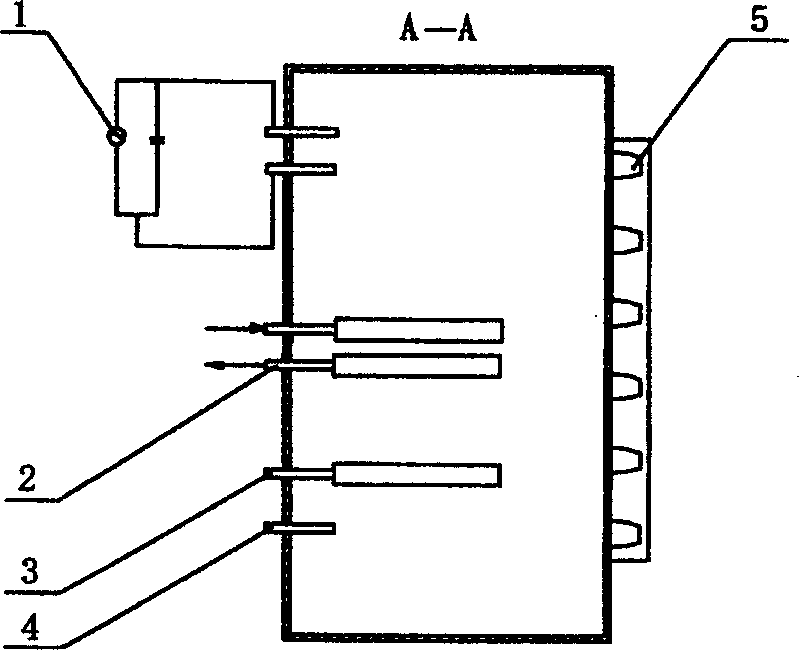

[0022] refer to figure 1 , figure 2 , image 3 and Figure 4 : Take six stations as an example, that is, six sets of heating devices and ejection mechanisms are used. The heating device adopts the electromagnetic induction heating method. It is equipped with an induction coil 8 on the outer wall of the heating hole, that is, the bushing 9. The induction coil 8 is wound by a water-passing copper pipe and fixed on the body. The two poles of 1 are connected, and at the same time communicate with the circulating water inlet and outlet joint 2. refer to Figure 6 : The induction coil is not in contact with the rivet, and the energy is transmitted through electromagnetic induction.

[0023] Its induction principle refers to Figure 8 .

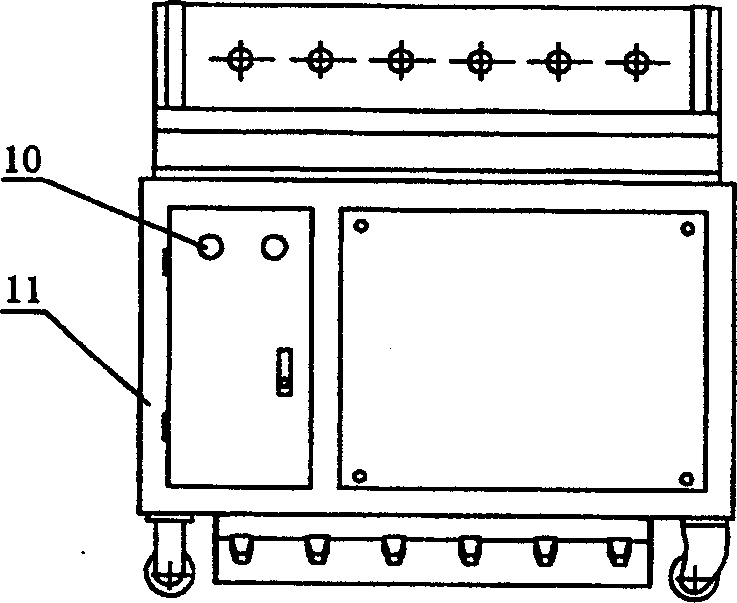

[0024] Four wheels are installed under the body 11 of the device, and its mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com