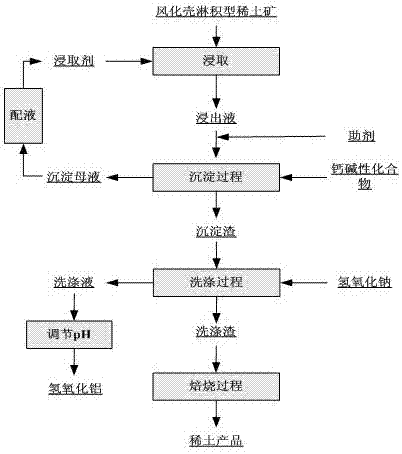

Method of recovering rare earth and aluminum from weathered elution-deposited rare earth ores

A weathering crust elution type, rare earth ore technology, which is applied in the field of rare earth and aluminum recovery, can solve the problems of reducing the purity of rare earth concentrate products, failing to obtain products, and the loss of aluminum resources, so as to improve the recovery rate of rare earth and avoid the loss of rare earth , The effect of eradicating ammonia nitrogen pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Magnesium sulfate solution was used to leach weathering crust elution-type rare earth ore to obtain a leach solution with an aluminum content of 0.05 g / L and a rare earth content of 0.3 g / L (calculated as REO). Add polyaspartic acid auxiliary agent to leachate, control the total molar concentration of auxiliary agent to be 0.05mol / L. Calcium oxide is then added to the leaching solution for precipitation, the precipitation temperature is 20°C, and the pH of the precipitation end point is 9.0; then solid-liquid separation and water washing are performed to obtain the precipitation mother liquor and precipitation slag. The pH of the precipitation mother liquor is adjusted to 1.5, and it is returned for leaching after replenishing magnesium sulfate. The precipitated slag is stirred and washed with a sodium hydroxide solution with a concentration of 0.3mol / L, and the liquid-solid ratio is controlled to be 1:0.5; then the solid-liquid is separated and washed with w...

Embodiment 2

[0039] Example 2: A weathering crust leached rare earth ore was leached with sulfate solution containing magnesium and sodium to obtain a leaching solution with an aluminum content of 0.1 g / L and a rare earth content of 0.5 g / L (calculated as REO). Add polyacrylic acid additives to the leaching solution to control the total molar concentration of the additives to 0.05mol / L. Calcium oxide is then added to the leaching solution for precipitation, the precipitation temperature is 20°C, and the pH of the precipitation end point is 9.0; then solid-liquid separation and water washing are performed to obtain the precipitation mother liquor and precipitation slag. The pH of the precipitation mother liquor is adjusted to 2.0, and the supplement of magnesium sulfate and sodium sulfate is returned for ore leaching. The precipitated slag is stirred and washed with a sodium hydroxide solution with a concentration of 0.3mol / L, and the liquid-solid ratio is controlled to be 1:0.5; then the s...

Embodiment 3

[0040] Example 3: The weathering crust elution-type rare earth ore was leached with sulfate and chloride solutions containing magnesium and potassium to obtain a leach solution with an aluminum content of 0.3 g / L and a rare earth content of 2 g / L (calculated as REO). Add polyaspartic acid and sodium ethylenediamine tetramethylene phosphonate mixing additives (molar ratio 0.5:1) to the leachate, and control the total molar concentration of the additives to 0.2mol / L. Calcium oxide is then added to the leaching solution for precipitation, the precipitation temperature is 40°C, and the pH of the precipitation end point is 10.0; then solid-liquid separation and water washing are performed to obtain the precipitation mother liquor and precipitation residue. The pH of the precipitation mother liquor is adjusted to 2.0, supplemented with sulfate and chloride solutions containing magnesium and potassium, and returned for leaching. The precipitated residue is stirred and washed with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com