Fermented biofertilizer prepared from waste vegetables, straw and livestock and poultry feces and preparation method thereof

A technology for fermenting organisms, livestock and poultry feces, which is applied in the preparation of organic fertilizers, organic fertilizers, and the treatment of bio-organic parts. It can solve the problems of large differences in the decomposition speed of organic matter, long cycles, and low fertilizer efficiency, so as to save water for washing. Process, high cost, high pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

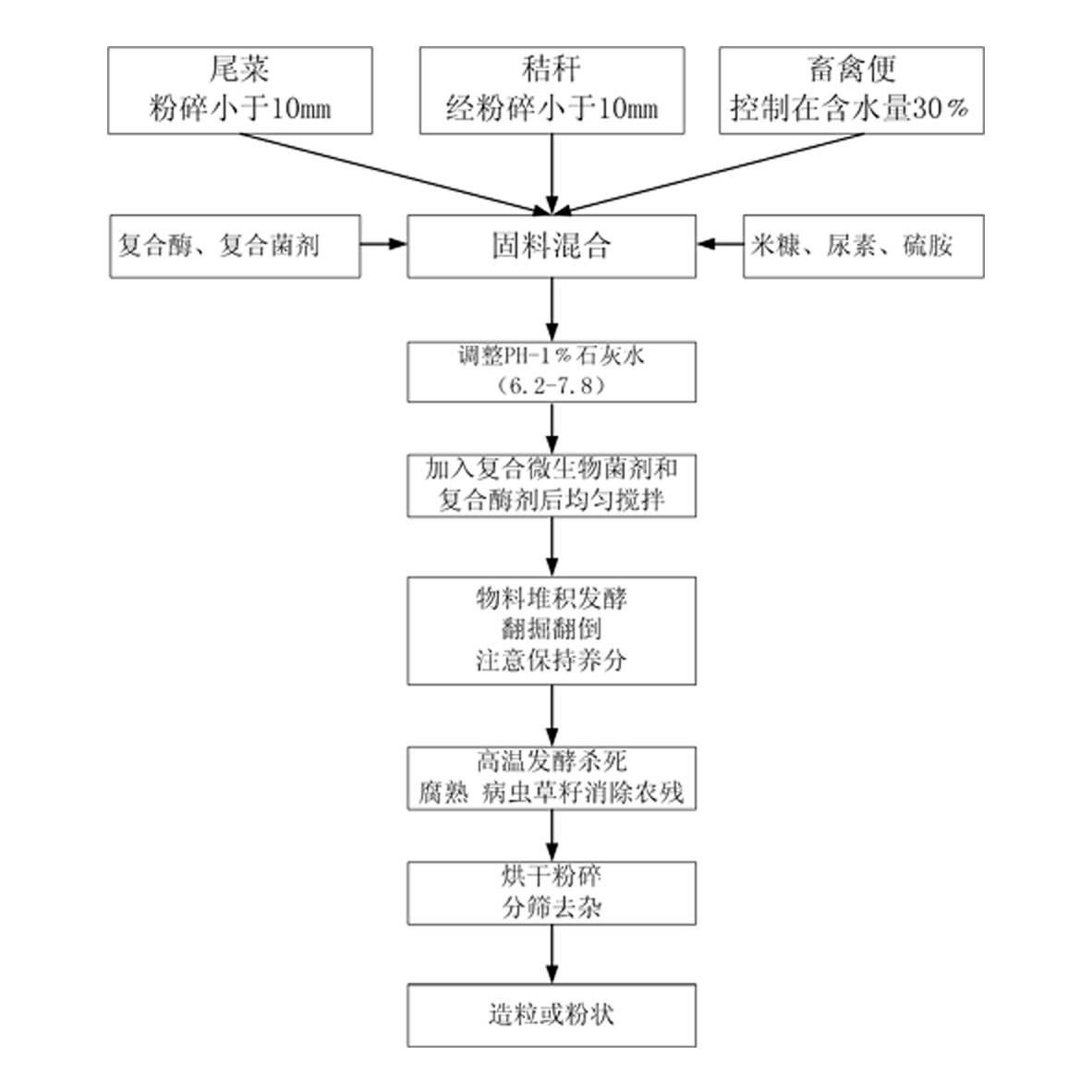

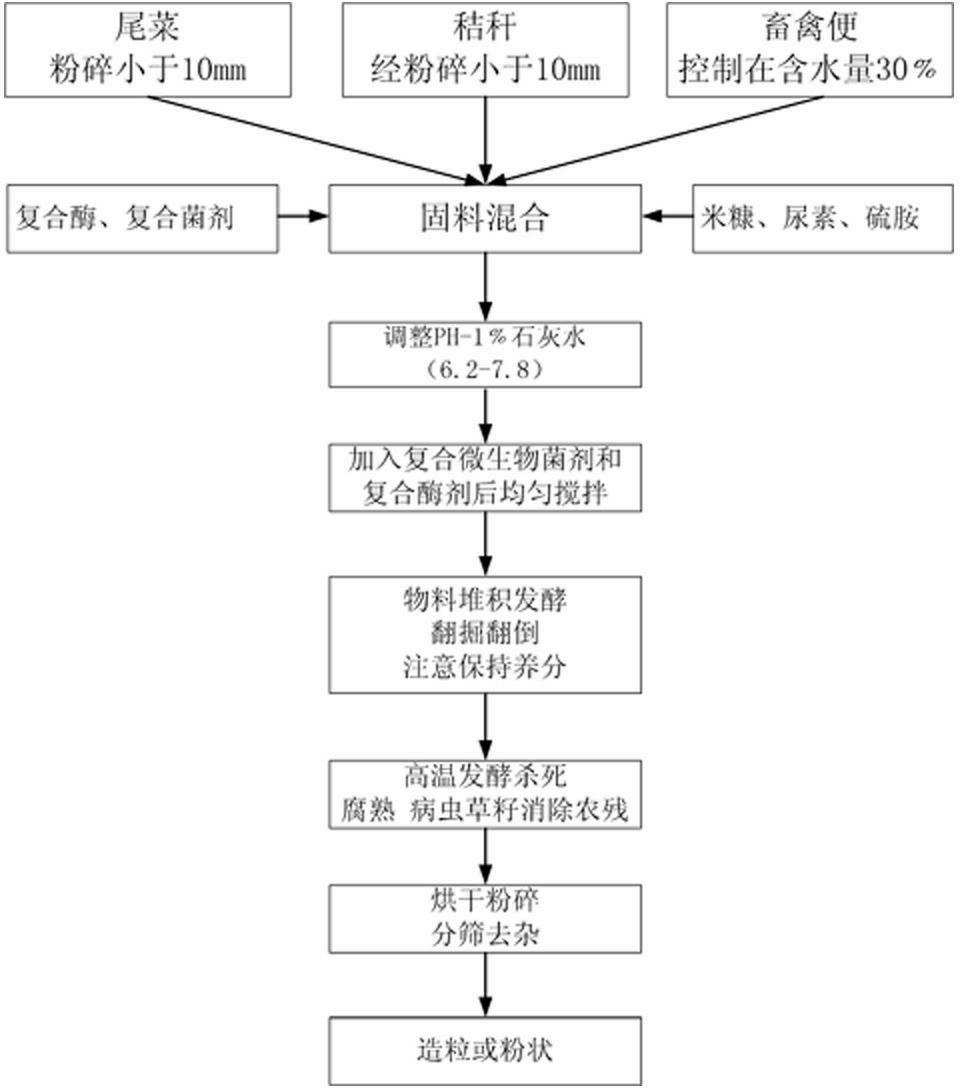

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: A kind of fermented bio-fertilizer of tail vegetables and straw, livestock and poultry and its method, comprising the following steps:

[0026] Add 50kg of corn stalks or sorghum stalks, 20kg of cow dung, 7kg of rice bran, 1.7kg of urea and 1.7kg of ammonium sulfate to 100 kg of cabbage tail vegetables and mix them, and adjust the water content of the mixed materials to 50-65% , according to the weight of the mixed material, add 0.1% compound bacterial agent and 0.008% compound enzyme, stir well, adjust the pH to 6.2, and undergo aerobic fermentation for 13 days to obtain the biological fertilizer product.

[0027] The compound enzyme is composed of 30% cellulase, 20% xylanase, 10% pectinase, 20% glucoamylase and 20% acid protease.

[0028] The composite bacterial agent is composed of 20% of Bacillus licheniformis, 30% of photosynthetic bacteria, 25% of thermoactinomycetes and 25% of Trichoderma viride.

[0029] Its product quality:

[0030] Organic matt...

Embodiment 2

[0034] Embodiment 2: A kind of fermented bio-fertilizer of tail vegetables and straw, livestock and poultry and its method, comprising the following steps:

[0035] Add 45kg of wheat straw or rice straw or barley straw or cereal straw or buckwheat straw, 18kg of pig manure, 6kg of rice bran, 2.0kg of urea and 1.7kg of ammonium sulfate to 90 kg of lotus tail vegetables and mix them. Adjust the water content of the material to 50-65%, add 0.08% compound bacterial agent and 0.009% compound enzyme according to the weight of the mixed material, stir well, control the water content of the fermentation material to 56%, adjust the pH to 6.6, and carry out aerobic fermentation for 12 days. A bio-fertilizer product is obtained.

[0036] The compound enzyme is composed of 25% cellulase, 15% xylanase, 20% pectinase, 20% glucoamylase and 20% acid protease.

[0037] The composite bacterial agent is composed of 25% of Bacillus licheniformis, 35% of photosynthetic bacteria, 20% of thermoacti...

Embodiment 3

[0043] Embodiment 3: A kind of fermented bio-fertilizer of tail vegetables and straw, livestock and poultry and its method, comprising the following steps:

[0044] Add 25kg of soybean stalks or broad bean stalks or pea stalks, 30kg of corn stalks, 10kg of sheep manure, 10kg of chicken manure, 9kg of rice bran, 2.0kg of urea and 1.7 After mixing with ammonium sulfate of kg, adjust the water content of the mixed material to 60%, add 0.12% compound bacterial agent and 0.008% compound enzyme according to the weight of the mixed material, stir well, adjust the pH to 6.2, and carry out aerobic fermentation for 15 days , to obtain biological fertilizer products.

[0045] The compound enzyme is composed of 35% of cellulase, 15% of xylanase, 10% of pectinase, 20% of glucoamylase and 20% of acid protease.

[0046] The composite microbial agent is composed of 20% of Bacillus licheniformis, 40% of photosynthetic bacteria, 20% of thermoactinomycetes, and 20% of Trichoderma viride.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com