Steel and zinc based alloy vacuum ion chromium plating technology capable of substituting current chromium electroplating technologies

A technology of electrochrome plating and ion plating, applied in ion implantation plating, vacuum evaporation plating, metal material coating technology, etc., can solve the problems of acid, alkali and salt polluting the environment, easily causing skin cancer, affecting adhesion, etc., to achieve The effect of eradicating environmental pollution and harm to human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

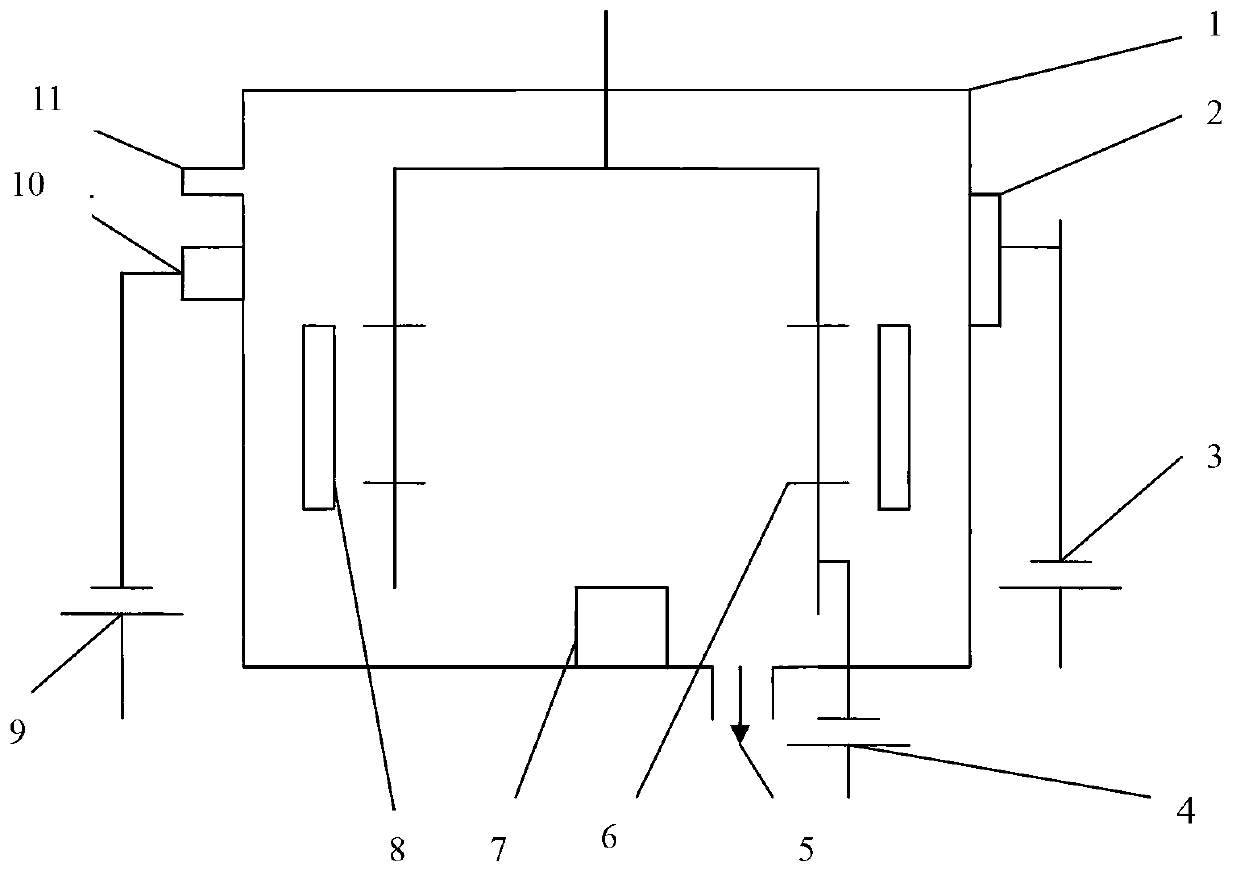

[0039] Embodiment 1. The iron and steel workpiece vacuum ion chromium plating process replaces the existing electroplating decorative chromium process and adopts cathodic arc plating-magnetron sputtering-electron beam ion plating technology such as figure 1 As shown, the vacuum ion chromium plating process for iron and steel workpieces is used to replace the current electroplating decorative chromium process.

[0040] Workpiece name: hardware, window frame, workpiece material: ordinary carbon steel

[0041] Step 1: The workpiece 6 is put into the vacuum chamber 1 after being polished, cleaned and dried.

[0042] Step 2: The vacuum chamber 1 is evacuated 5, and the vacuum degree reaches 3X10-3Pa.

[0043] Step 3: start the thermal heating device 8, and the temperature of the workpiece 6 is less than 200°C.

[0044] Step 4: The workpiece 6 is sputtered and cleaned, the ion source is fed with argon (Ar) 11, the vacuum degree is adjusted to 5Pa, the workpiece 6 is turned on with...

Embodiment 2

[0061] Embodiment 2. Zinc-based alloy vacuum ion plating cobalt process replaces existing electroplating decorative chromium process, adopts cathodic arc plating-magnetron sputtering-electron beam ion plating technology such as figure 1 As shown, the zinc-based alloy vacuum ion cobalt plating process replaces the current electroplating decorative chromium process.

[0062] Workpiece name: door and window handles, faucets, bathroom appliances, material: zinc-based alloy

[0063] Step 1: The workpiece 6 is put into the vacuum chamber 1 after polishing, cleaning and drying.

[0064] Step 2: The vacuum chamber 1 is evacuated 5, and the vacuum degree reaches 3X10-3Pa.

[0065] Step 3: The workpiece 6 starts the heating device 8, and the temperature of the workpiece 6 is <90°C.

[0066] Step 4: The workpiece 6 is sputtered and cleaned, the ion source is fed with argon (Ar) 11, the vacuum degree is adjusted to 2Pa, the workpiece 6 is turned on to charge the negative bias power supp...

Embodiment 3

[0083] Embodiment 3. Iron and steel workpiece vacuum ion plating ultra-hard chromium coating process replaces existing electroplating hard chromium process,

[0084] Cathodic arc plating-magnetron sputtering-electron beam ion plating technology such as figure 1 As shown, the vacuum ion plating of chromium nitride and ion chromium plating composite coating process on iron and steel workpieces replaces the current electroplating hard chromium process,

[0085] Workpiece name: wrench, machine tool thimble, workpiece material: 45

[0086] Step 1: The workpiece 6 is put into the vacuum chamber 1 after being polished and ultrasonically cleaned and dried.

[0087] Step 2: The vacuum chamber 1 is evacuated 5, and the vacuum degree reaches 2X10-3Pa.

[0088] Step 3: Start the heating device 8, and the temperature of the workpiece 6 is less than 195°C.

[0089] Step 4: The workpiece 6 is sputtered and cleaned, the ion source is fed with argon (Ar) 11, the vacuum degree is adjusted to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com