Liquid forging die and method for crusher jaw plates

A technology of liquid die forging and crushing machine, which is applied in the field of liquid die forging dies, and can solve the problems of low production efficiency of bimetallic composite jaw plates, inability to form a large-thick wear-resistant layer, and weak combination of ingots and substrates. Achieve the effect of eradicating waste sand pollution, avoiding welding failure, and smooth appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Embodiment 1, the liquid die forging of high manganese steel jaw plate

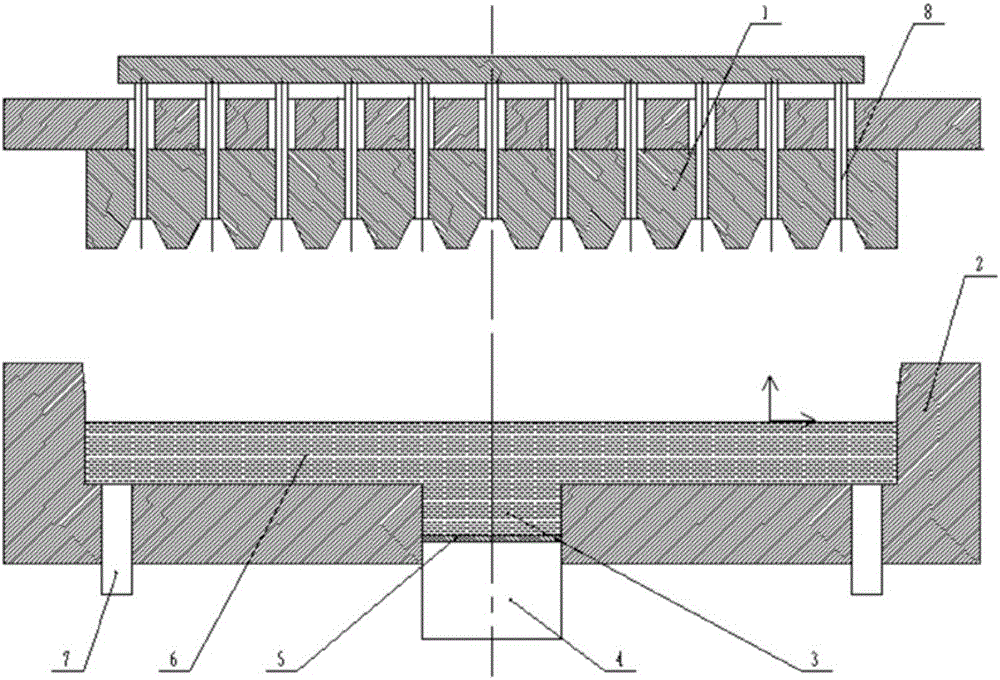

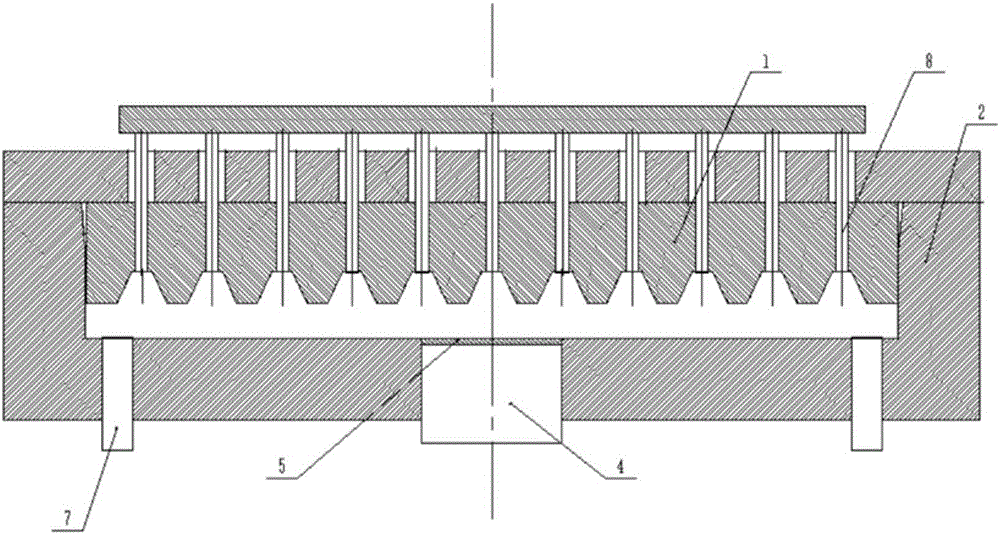

[0068] A liquid die forging die for a jaw plate of a crusher, comprising an upper punch 1, a lower die 2, a lower punch 4, an upper ejector rod 8 and a lower ejector rod 7; the lower die 2 has a lower die cavity inside.

[0069] The upper pressing head 1 is installed on the pressurizing equipment, and the shape and size of its lower end surface are adapted to the shape and size of the working surface of the jaw plate, and can be inserted into the lower mold cavity to move up and down to provide downward pressure for The working surface of the jaw plate is formed, and anti-wear teeth matching the lower end surface of the upper pressing head 1 are formed on the working surface of the jaw plate.

[0070] The unilateral movement gap between the two end sidewalls of the upper pressing head 1 and the two end sidewalls in the lower mold cavity is 0.1 mm.

[0071] The upper indenter 1 is made of hot work ...

Embodiment 2

[0090] Embodiment 2, a kind of high chromium cast iron jaw plate liquid die forging

[0091] A liquid die forging die for a jaw plate of a crusher, comprising an upper punch 1, a lower die 2, a lower punch 4, an upper ejector rod 8 and a lower ejector rod 7; the lower die 2 has a lower die cavity inside.

[0092] The upper pressing head 1 is installed on the pressurizing equipment, and the shape and size of its lower end surface are adapted to the shape and size of the working surface of the jaw plate, and can be inserted into the lower mold cavity to move up and down to provide downward pressure for The working surface of the jaw plate is formed, and anti-wear teeth matching the lower end surface of the upper pressing head 1 are formed on the working surface of the jaw plate.

[0093] On the basis of the above solution, the unilateral movement gap between the two end side walls of the upper indenter 1 and the two end side walls in the lower mold cavity is 0.18mm.

[0094]The...

Embodiment 3

[0113] Embodiment 3, low alloy steel jaw plate

[0114] A liquid die forging die for a jaw plate of a crusher, comprising an upper punch 1, a lower die 2, a lower punch 4, an upper ejector rod 8 and a lower ejector rod 7; the lower die 2 has a lower die cavity inside.

[0115] The upper pressing head 1 is installed on the pressurizing equipment, and the shape and size of its lower end surface are adapted to the shape and size of the working surface of the jaw plate, and can be inserted into the lower mold cavity to move up and down to provide downward pressure for The working surface of the jaw plate is formed, and anti-wear teeth matching the lower end surface of the upper pressing head 1 are formed on the working surface of the jaw plate.

[0116] The unilateral movement gap between the two end sidewalls of the upper pressing head 1 and the two end sidewalls in the lower mold cavity is 0.25 mm.

[0117] The upper indenter 1 is made of hot work die steel, and there are exhau...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com