Method for casting brake bottom plate blank for automobile, and casting mold used by method

The technology of brake base plate and blank is applied in the casting field of automobile brake base plate blank, which can solve the problems of shrinkage cavity, shrinkage porosity, material loss, etc., and achieve the effects of improving cutting performance, eradicating dust pollution and preventing shrinkage defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

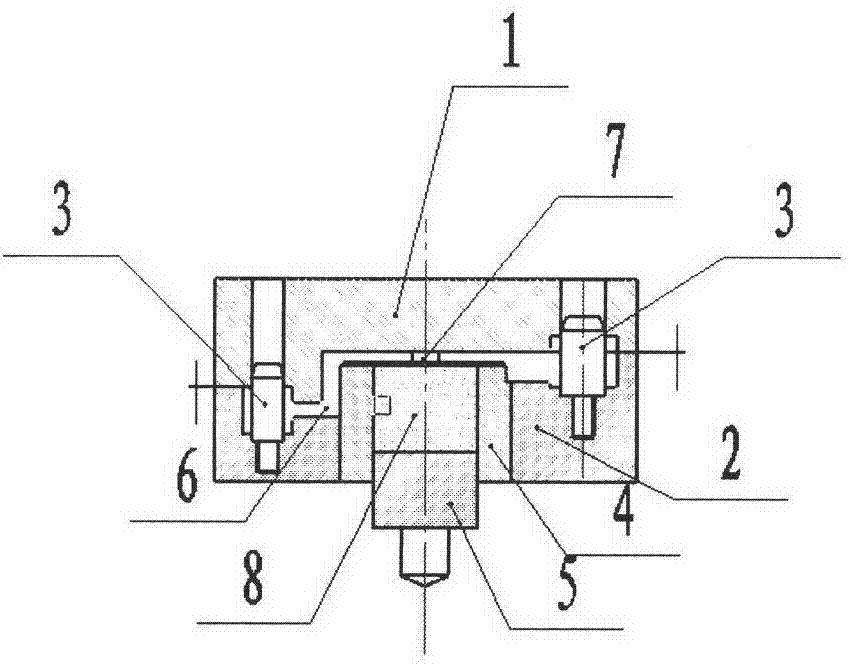

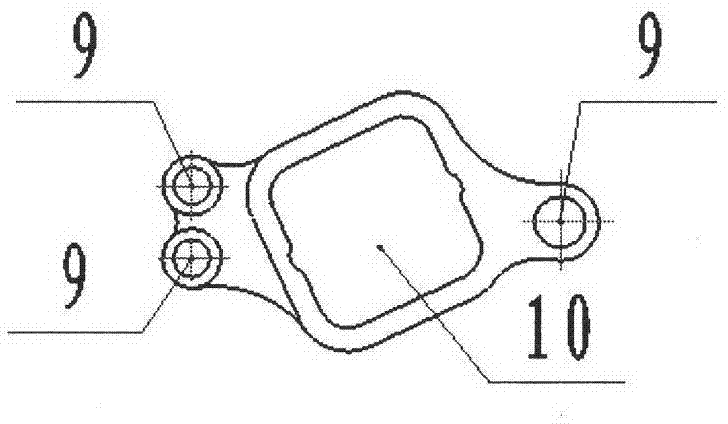

[0026] A method for casting a brake base blank for an automobile, comprising the steps of:

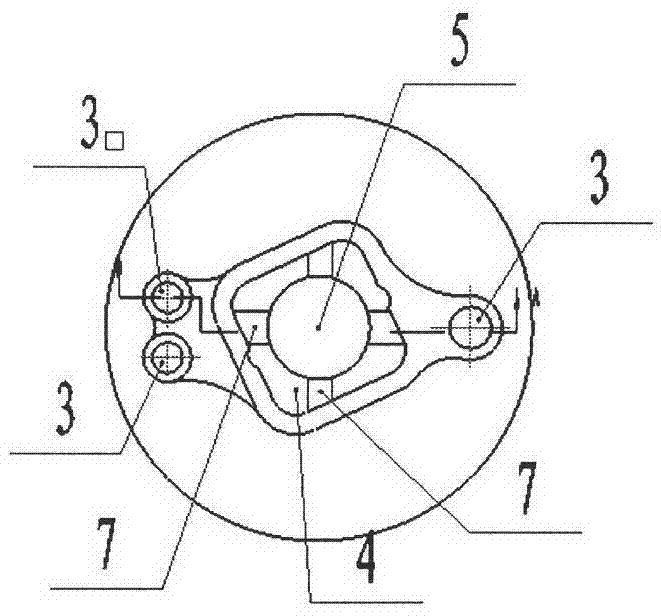

[0027] Step 1: Pour ZG270-500 molten steel 8 at a temperature of 1420°C to the pressure chamber 4 to the lower edge of the ingate 7;

[0028] Step 2: The pressure head 5 exerts an upward pressure of 1 MPa on the molten steel 8, so that the molten steel 8 passes through the inner runner 7, bypasses the core 3 installed on the lower mold 2 and the outer wall of the upper port of the pressure chamber 4, and fills the upper mold 1 and the lower mold 2 The mold cavity 6 formed by closing;

[0029] Step 3 Pressurize the molten steel 8 in the pressure chamber 4 to 20MPa with the pressure head 5, and keep the pressure until the molten steel 8 in the mold cavity 6 is completely solidified;

[0030] Step 4 Open the casting mold to take out the workpiece, and use the waste heat of the workpiece to perform annealing treatment to obtain the brake base plate blank of the present invention.

[0031...

Embodiment approach 2

[0036] A method for casting a brake base blank for an automobile, comprising the steps of:

[0037] Step 1 Pour ZG270-500 molten steel 8 at a temperature of 1450°C to the pressure chamber 4 to the lower edge of the ingate 7;

[0038] Step 2: The pressure head 5 exerts an upward pressure of 5 MPa on the molten steel 8, so that the molten steel 8 passes through the inner runner 7, bypasses the core 3 installed on the lower mold 2 and the outer wall of the upper port of the pressure chamber 4, and fills the upper mold 1 and the lower mold 2 The mold cavity 6 formed by closing;

[0039] Step 3 Pressurize the molten steel 8 in the pressure chamber 4 to 80MPa with the pressure head 5, and keep the pressure until the molten steel 8 in the mold cavity 6 is completely solidified;

[0040] Step 4 Open the casting mold to take out the workpiece, and use the waste heat of the workpiece to perform annealing treatment to obtain the brake base plate blank of the present invention.

[0041]...

Embodiment approach 3

[0046] A method for casting a brake base blank for an automobile, comprising the steps of:

[0047] Step 1: pour ZG270-500 molten steel 8 with a temperature higher than 1500°C to the pressure chamber 4 to the lower edge of the ingate 7;

[0048] Step 2: The pressure head 5 exerts an upward pressure of 9 MPa on the molten steel 8, so that the molten steel 8 passes through the inner runner 7, bypasses the core 3 installed on the lower mold 2 and the outer wall of the upper port of the pressure chamber 4, and fills the upper mold 1 and the lower mold 2 The mold cavity 6 formed by closing;

[0049] Step 3 Pressurize the molten steel 8 in the pressure chamber 4 to 150MPa with the pressure head 5, and keep the pressure until the molten steel 8 in the mold cavity 6 is completely solidified;

[0050] Step 4 Open the casting mold to take out the workpiece, and use the waste heat of the workpiece to perform annealing treatment to obtain the brake base plate blank of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com