Process for zero-discharge treatment of o-phenylenediamine sodium sulfide reduction wastewater

An o-phenylenediamine and zero-emission technology, which is applied in the field of zero-emission treatment of o-phenylenediamine sulfide alkali reduction wastewater technology, can solve problems such as environmental pollution, and achieve significant environmental benefits, small investment, and simple and practical effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will carry out the basic chemical substance composition (by weight percentage) of treating waste water as:

[0026] O-phenylenediamine (C 6 h 8 N 2 )0.8-1.2% sodium sulfide (Na 2 S) 1.15-2.25%

[0027] Sodium hydroxide (NaOH) 2.4-3.6% Sodium thiosulfate (NaOH) 2 S 2 o 3 )17.5-20%;

[0028] Sodium chloride (NaCl) 8%-10% Other organic matter 0.8%-1.4%

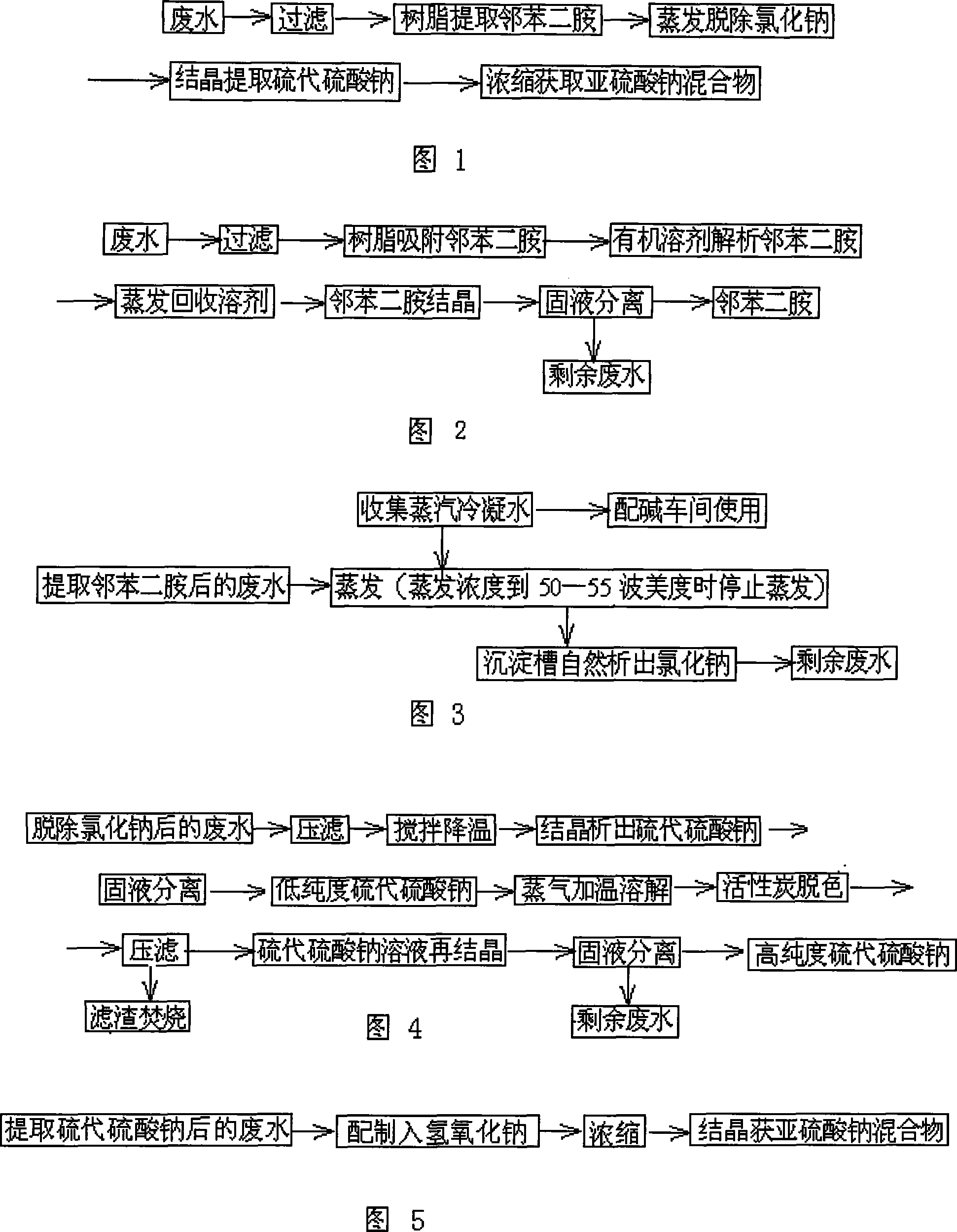

[0029] The following is a brief description of the process implementation process in combination with the process flow diagram:

[0030] (1) Filter waste water. A filter press, such as a plate and frame filter press, is used to remove water-insoluble matter and other impurities in the wastewater, and the filtered wastewater is placed in a storage tank (tank).

[0031] (2) Resin adsorption extracts o-phenylenediamine in wastewater. According to laboratory analysis, there is about 1% o-phenylenediamine in the wastewater, which is one of the main components that cause the wastewater to be toxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com