Potassium sulfate extracted from sintering dust separation ash and method for producing the same

A technology of potassium sulfate and ammonium sulfate, applied in the field of extraction of potassium sulfate and its preparation, can solve the problems of large amount of leaching water and water resource consumption, and achieve the effects of improving purity, reducing energy consumption and improving yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

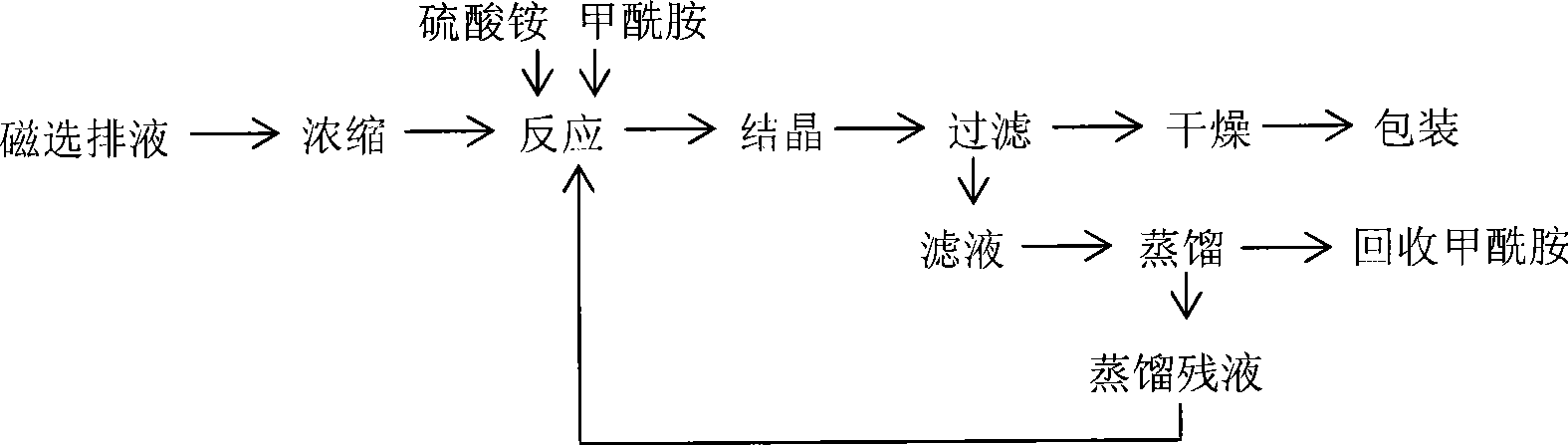

Method used

Image

Examples

Embodiment 1

[0029] 100 grams of dedusting ash, add 1000mL deionized water to soak for 3 days, filter, concentrate the filtrate to 100mL, analyze the K in the concentrated solution + The content is 9.34 grams / 100mL. Add ammonium sulfate 15 grams (K + :SO 4 2+ =2.1:1), then add 50g formamide, react at 80°C for 2 hours to obtain potassium sulfate crystals, dry to obtain 18.40g potassium sulfate, the filtrate enters the distillation tower, and distills at 90°C to recover formamide 47.5g.

Embodiment 2

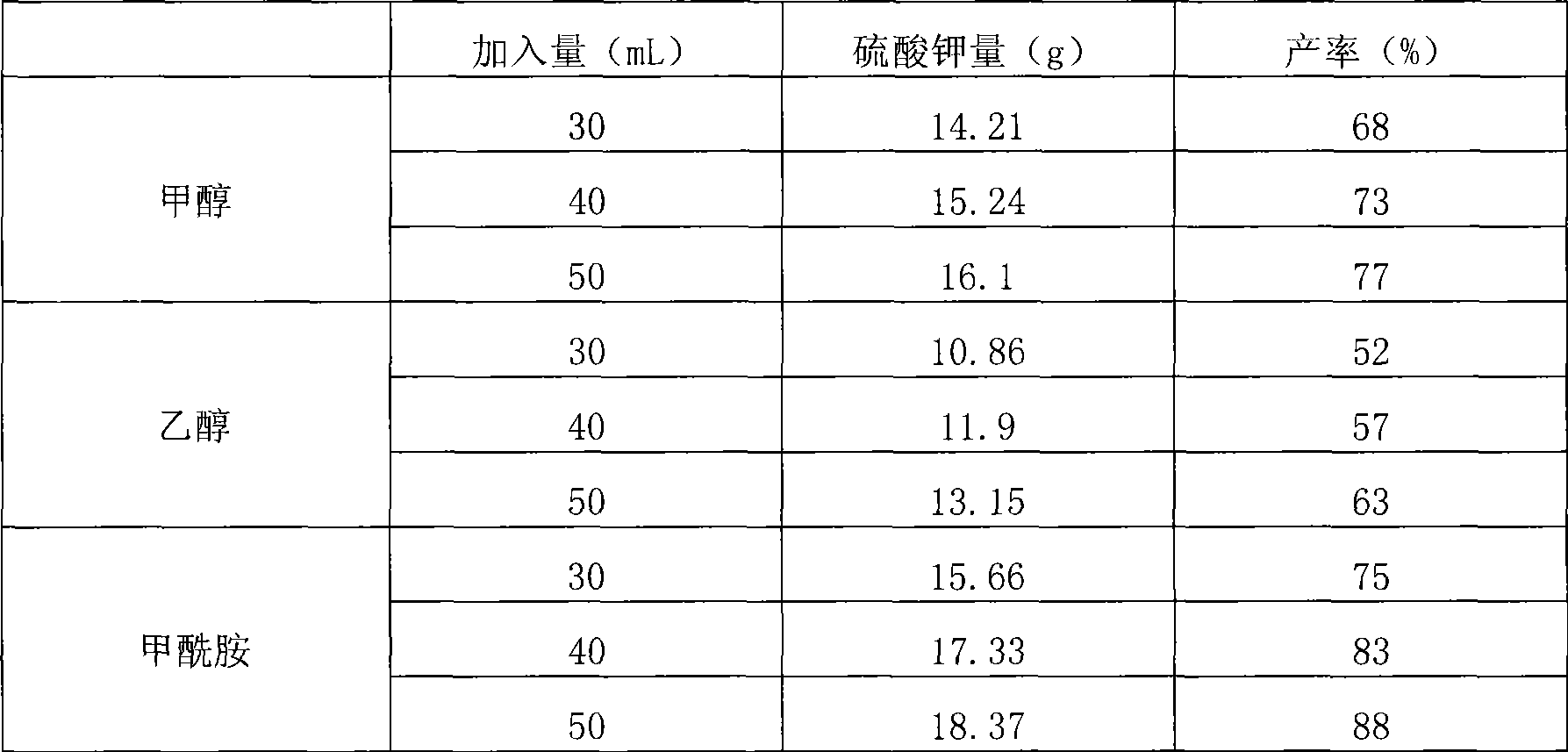

[0031] Other is the same as embodiment 1, and difference is that the organic solvent that adds is different, and following table is the impact of different solvents on potassium sulfate productive rate.

[0032] Table 1 The influence of adding different solvents on the yield of potassium sulfate in 100mL concentrated solution

[0033]

[0034] As can be seen from the above experimental results, adding formamide can significantly increase the yield of potassium sulfate. When the amount of formamide is 30-35%, the yield of potassium sulfate can be close to 90%.

Embodiment 3

[0036] 150 grams of dust, add 1500mL deionized water to soak for 3 days, filter, concentrate the filtrate to 150mL, analyze the K in the concentrate + The content is 10.5 g / 100mL. Add ammonium sulfate 16.86 grams (K + :SO 4 2+ =2.1:1), then add 50g formamide, and react for 2 hours at 80°C to obtain crystallization of potassium sulfate, dry to obtain 20.69g of potassium sulfate, and the filtrate can be seen from the search results, the patent CN101234766 also utilizes the sintering process of the iron and steel plant Electrostatic precipitator ash adopts the conventional method of producing potassium chloride, which is more conducive to the utilization of potassium in sintering dust removal ash than the production of potassium sulfate. Potassium sulfate will not cause soil compaction in the production of compound fertilizers; the use of formamide than patented CN101234766 adopts SDD to more effectively improve the yield of potassium salt; after adding formamide, the amount o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com