Method for treating acid waste water of disperse dye

A technology for acidic wastewater and disperse dyes, which is applied in water/sewage multi-stage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc. It can solve secondary pollution, high safety risks, and skin irritation and other issues, to achieve the effect of reducing production and operating costs, good economic feasibility, and no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

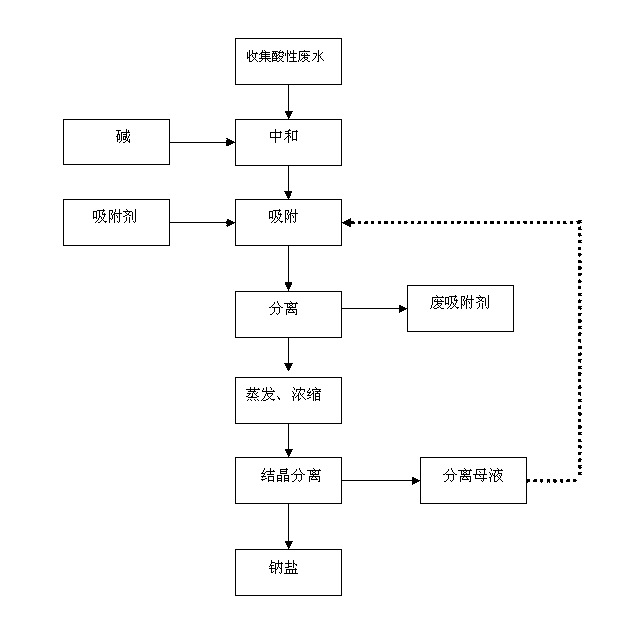

Method used

Image

Examples

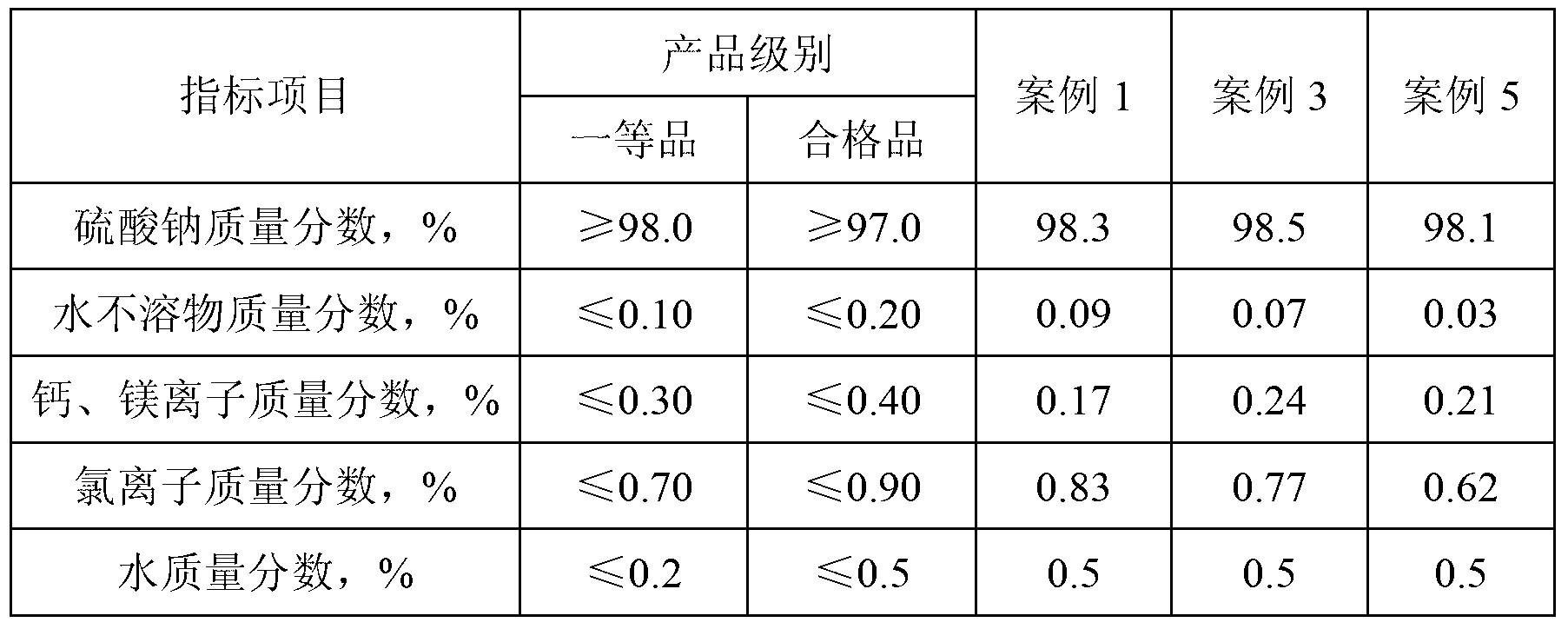

Embodiment 1

[0035]Add sulfuric acid acid wastewater from industrial production (containing 10% sulfuric acid, COD value 5000-7000mg / l) into the neutralization tank, start stirring, and add caustic soda to neutralize the acid wastewater until the pH value of the solution is 5.0-7.0, keep the temperature Add activated carbon adsorbent with 0.5% of the total mass of wastewater at 50°C, stir continuously for 2 hours, filter and sample to detect that the COD value of the solution has dropped to 1000-1200mg / l, and the removal rate of organic matter is above 80%, and the filtrate is evaporated and concentrated, and the crystals are filtered out Sodium sulfate salt has been tested to meet the industry standard of sodium sulfate salt. It can be used as a filler for reactive dyes. The concentrated separation liquid is returned to the adsorption system for continued adsorption. The evaporated hot water is used for product washing.

Embodiment 2

[0037] Add hydrochloric acid acid wastewater from industrial production (containing 7% hydrochloric acid, COD value 4000-5000mg / l) into the neutralization tank, start stirring, neutralize the acid wastewater with a mixture of sodium carbonate and baking soda to a pH value of 5.0-7.0, and end For neutralization, add 1% water to the neutralization liquid to mix the adsorbent with activated carbon and diatomite, the mixing ratio (mass ratio) of activated carbon and diatomite is 1:1, stir continuously for 1.5h, filter and separate the adsorbent, and take a sample to test the solution The COD value drops to 500-800mg / l, the adsorption operation is completed, the sodium chloride solution is evaporated and concentrated, and the sodium chloride salt is separated, which meets the industry standard after testing and can be used for salting out in industrial production; the mother liquor is concentrated and filtered back to The adsorption system continues to adsorb; the evaporated and con...

Embodiment 3

[0039] Put sulfuric acid wastewater from industrial production (containing 15% sulfuric acid, COD value 6000-7000mg / L) into the adsorption kettle, use 4% of the mass of sulfuric acid wastewater to be treated with a mixture of activated carbon and diatomite, activated carbon and diatomite The mixing ratio (mass ratio) is 1:3, and the adsorption is carried out. The COD value of the water sample is taken to drop to 500-600mg / l. After the adsorption operation is completed, the adsorbent is separated. Evaporate and concentrate the neutralizing liquid, separate the tidal product of sodium sulfate crystallization, take a sample after drying to meet the industrial filler standard, concentrate and filter the mother liquor and return it to the adsorption system to continue the adsorption, and reuse the evaporated and condensed hot water for heating other industrial products, or This product produces a hydrating top.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com