Method for preparing calcium carbonate and co-producing sodium sulfate by using phosphorus gypsum and soda ash

A technology of phosphogypsum and calcium carbonate, applied in the field of comprehensive treatment and utilization of phosphogypsum, can solve the problem of high cost and achieve the effects of small investment, simple production equipment and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

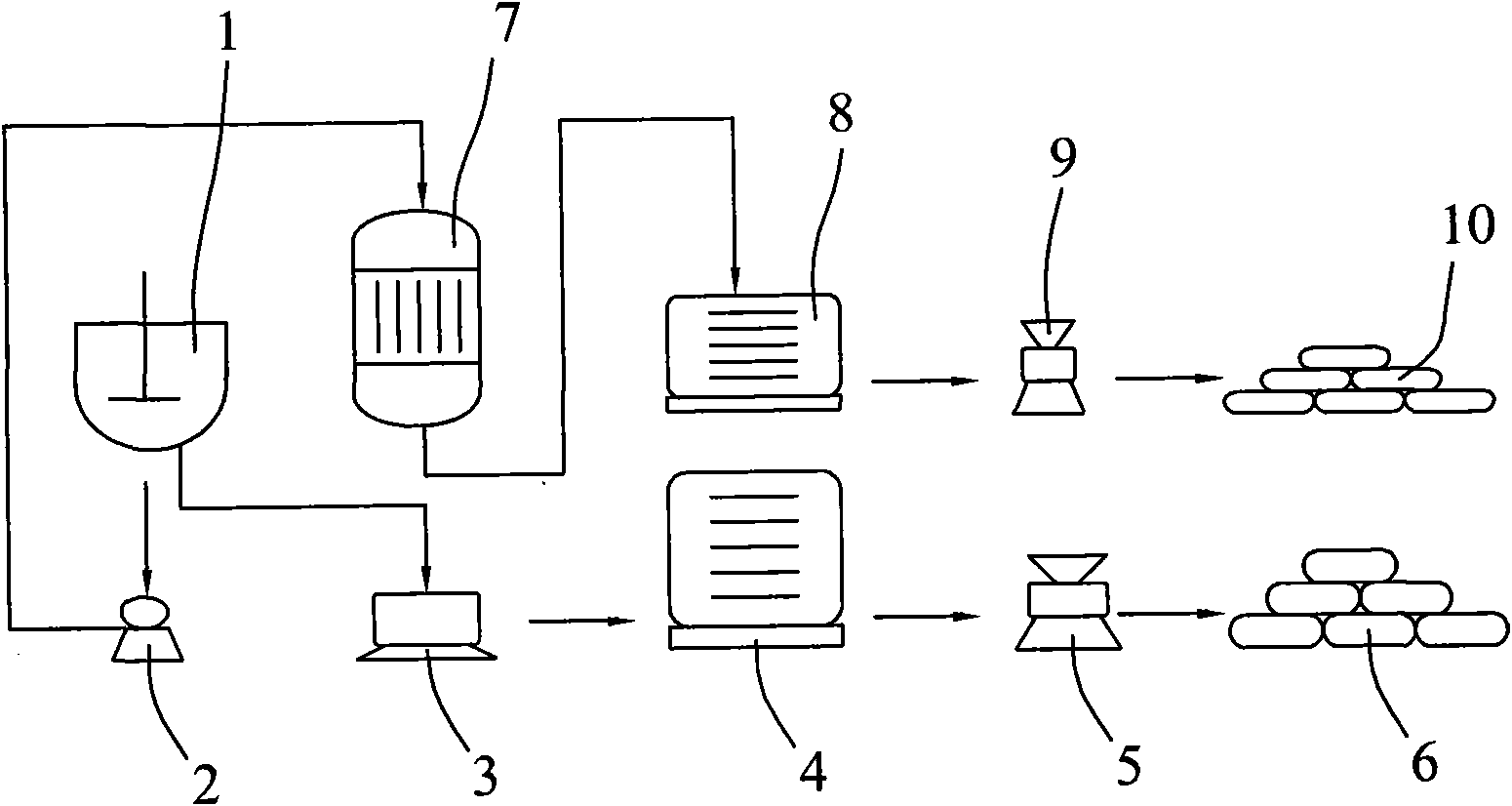

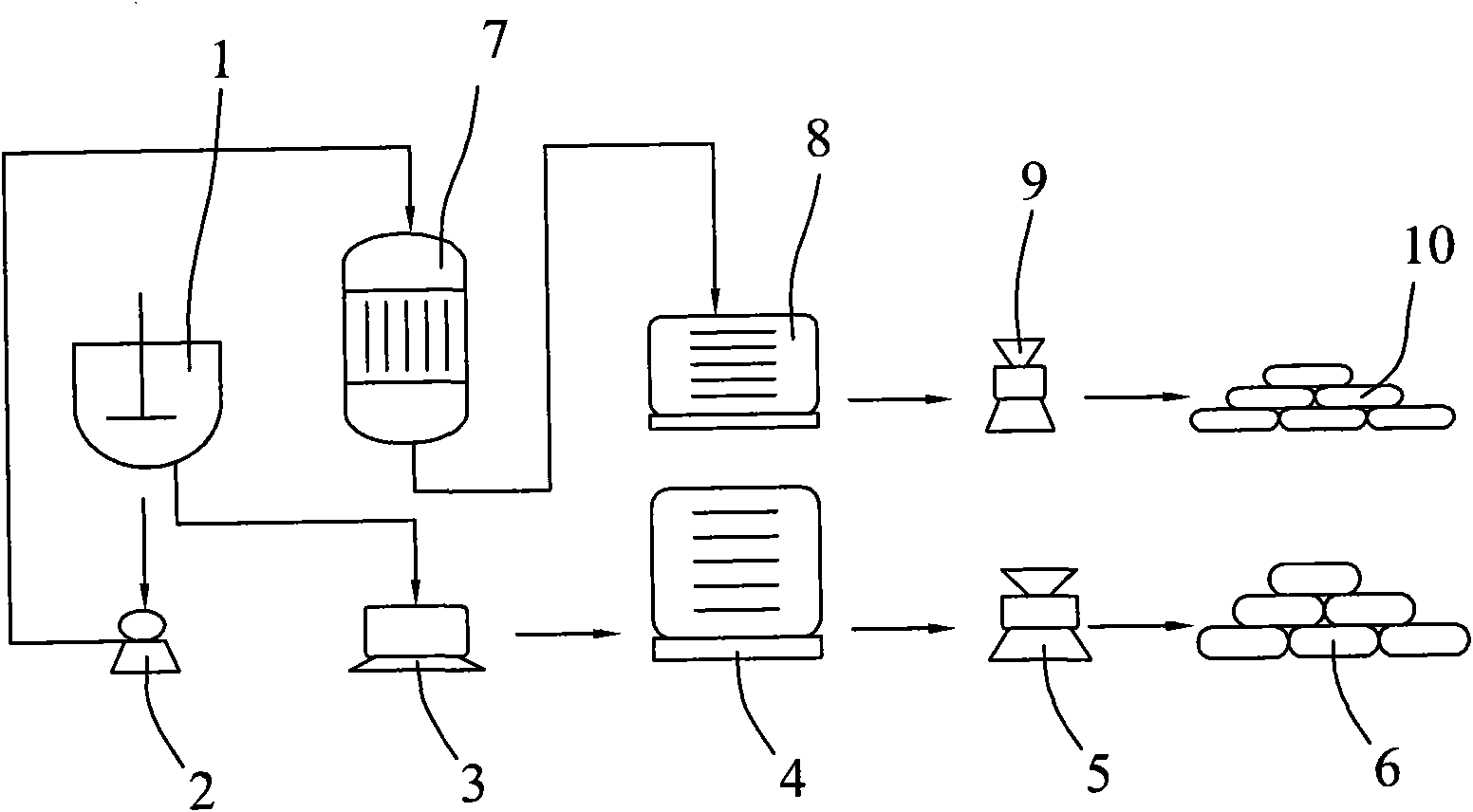

[0022] A kind of method that utilizes phosphogypsum and soda ash to prepare calcium carbonate to co-produce sodium sulfate, first convert the amount of the pure substance calcium sulfate contained in the industrial phosphogypsum product, the phosphogypsum containing 400kg calcium sulfate and the soda ash that dissolves are mixed according to calcium sulfate The ratio with the mass of sodium carbonate pure substance is 1: 0.58 in the reactor (1) that drops into, carries out chemical reaction under slow stirring; Then reaction product is suction-filtered in suction filter (2), obtains clarified sodium sulfate Solution and calcium carbonate filter cake; After the calcium carbonate filter cake of gained is washed with water, centrifugal through centrifuge (3), solid-liquid separation, solid is dried through drier (4), pulverizes through first pulverizer (5) again, Obtain calcium carbonate (6) product 218.87kg; Sodium sulfate solution is sent into underpressure distiller (7) and car...

Embodiment 2

[0024] A kind of method that utilizes phosphogypsum and soda ash to prepare calcium carbonate to co-produce sodium sulfate, first convert the amount of the pure substance calcium sulfate contained in the industrial phosphogypsum product, the phosphogypsum containing 500kg calcium sulfate and the soda ash dissolved are calculated according to the amount of calcium sulfate The ratio with the mass of sodium carbonate pure substance is 1: 0.78 drops in the reactor (1), carries out chemical reaction under slow stirring; Then reaction product is suction-filtered in suction filter (2), obtains clarified sodium sulfate Solution and calcium carbonate filter cake; After the calcium carbonate filter cake of gained is washed with water, centrifugal through centrifuge (3), solid-liquid separation, solid is dried through drier (4), pulverized through first pulverizer (5) again, Obtain calcium carbonate (6) product 367.92kg; Sodium sulfate solution is sent into underpressure distiller (7) and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com