Method for preparing potassium sulfate

A technology of potassium sulfate and sodium sulfate, which is applied in the preparation of sulfate/bisulfate, can solve the problems of research work staying in the experimental stage and increasing production costs, and achieve the goals of shortening the growth cycle, improving production efficiency, and saving fresh water resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] 1) Potassium mixed salt ore, potassium chloride, sodium sulfate, the first mother liquor (consist of: 1.9% K + , 7.0% Mg 2+ , 20.1% Cl - , 4.8% SO 4 2- , 0.5% Na + , 68.3% H 2 0), the second mother liquor (high-sodium mother liquor) is mixed in the mass ratio of 9:1.2:5.5:16:13.2 and dropped into a transformation tank, and stirred at a speed of 230~270r / min for 1.0h at room temperature to fully transform the raw materials, React to obtain a solid-liquid mixture;

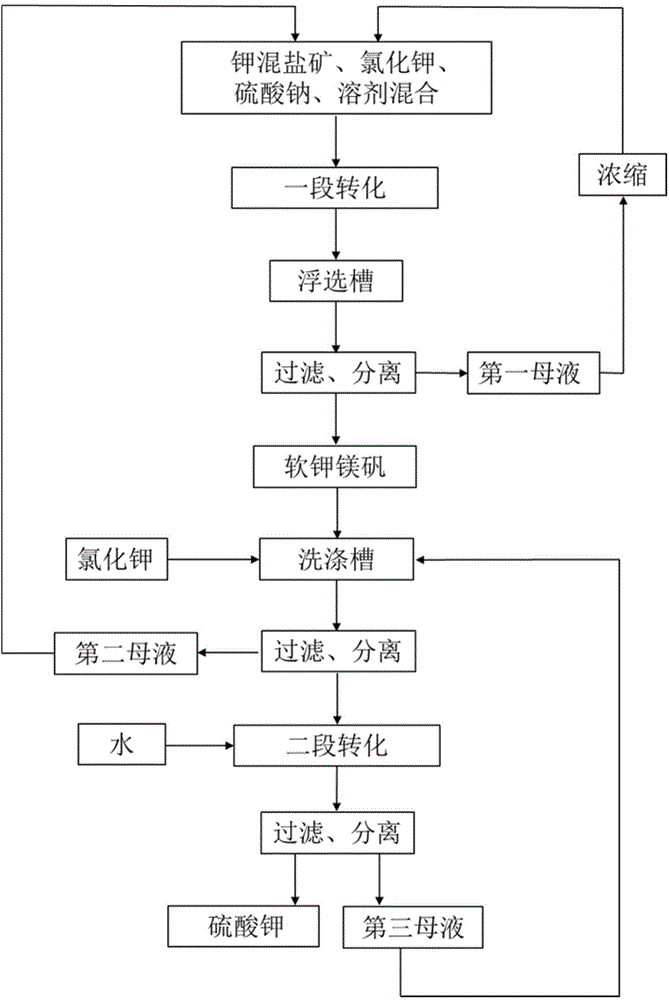

[0052] 2) Import the solid and liquid mixture obtained in step 1) into the flotation tank, adjust the volume ratio of solid and liquid to 1:4, add flotation reagents for flotation, and then filter and separate the obtained flotation foam to obtain soft Kobeinite and the first mother liquor (such as figure 1 shown in ), the first mother liquor is introduced into the tail salt pond to be evaporated and concentrated, and returned to step 1) for recycling in the first section of the conversion tank, and can...

Embodiment 2

[0057] 1) Potassium mixed salt ore, potassium chloride, sodium sulfate, salt lake brine (salt lake brine is composed of: 1.9% K + , 7.0% Mg 2+ , 20.1% Cl - , 4.8% SO 4 2- , 0.5% Na + , 68.3% H 2 0), the second mother liquor (high-sodium mother liquor) is mixed and dropped into a transformation tank in a mass ratio of 12:1.5:7:20:16.8, and stirred at a speed of 230 to 270r / min for 1.0h at room temperature to fully transform the raw materials, React to obtain a solid-liquid mixture;

[0058] 2) Import the solid and liquid mixture obtained in step 1) into the flotation tank, adjust the volume ratio of solid and liquid to 1:4, add flotation reagents for flotation, and then filter and separate the obtained flotation foam to obtain soft Kobeinite and the first mother liquor (such as figure 1 shown in ), the first mother liquor is introduced into the tailing salt pond to be evaporated and concentrated, and returned to step 1) as the salt lake brine for recycling in the first s...

Embodiment 3

[0063] 1) Potassium mixed salt ore, potassium chloride, sodium sulfate, salt lake brine (salt lake brine is composed of: 1.9% K + , 7.0% Mg 2+ , 20.1% Cl - , 4.8% SO 4 2- , 0.5% Na + , 68.3% H 2 0), the second mother liquor (high-sodium mother liquor) is mixed and dropped into a transformation tank in a mass ratio of 10:1.5:7:18:17.1, and stirred at a speed of 230 to 270r / min for 1.0h at room temperature to fully transform the raw materials, React to obtain a solid-liquid mixture;

[0064] 2) Import the solid and liquid mixture obtained in step 1) into the flotation tank, adjust the volume ratio of solid and liquid to 1:4, add flotation reagents for flotation, and then filter and separate the obtained flotation foam to obtain soft Kobeinite and the first mother liquor (such as figure 1 shown in ), the first mother liquor is introduced into the tailing salt pond to be evaporated and concentrated, and returned to step 1) as the salt lake brine to be recycled in the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com