Recovery method and recovery device of 4A zeolite mother liquor

A recovery method and technology of a recovery device, applied in the field of recovery of 4A zeolite mother liquor, can solve the problems affecting the unit cost of alumina production, increase the operation cost of the production process, and the difficulty of liquid-solid separation, so as to achieve low manufacturing cost and reduce scarring Speed, Composition and Simple Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

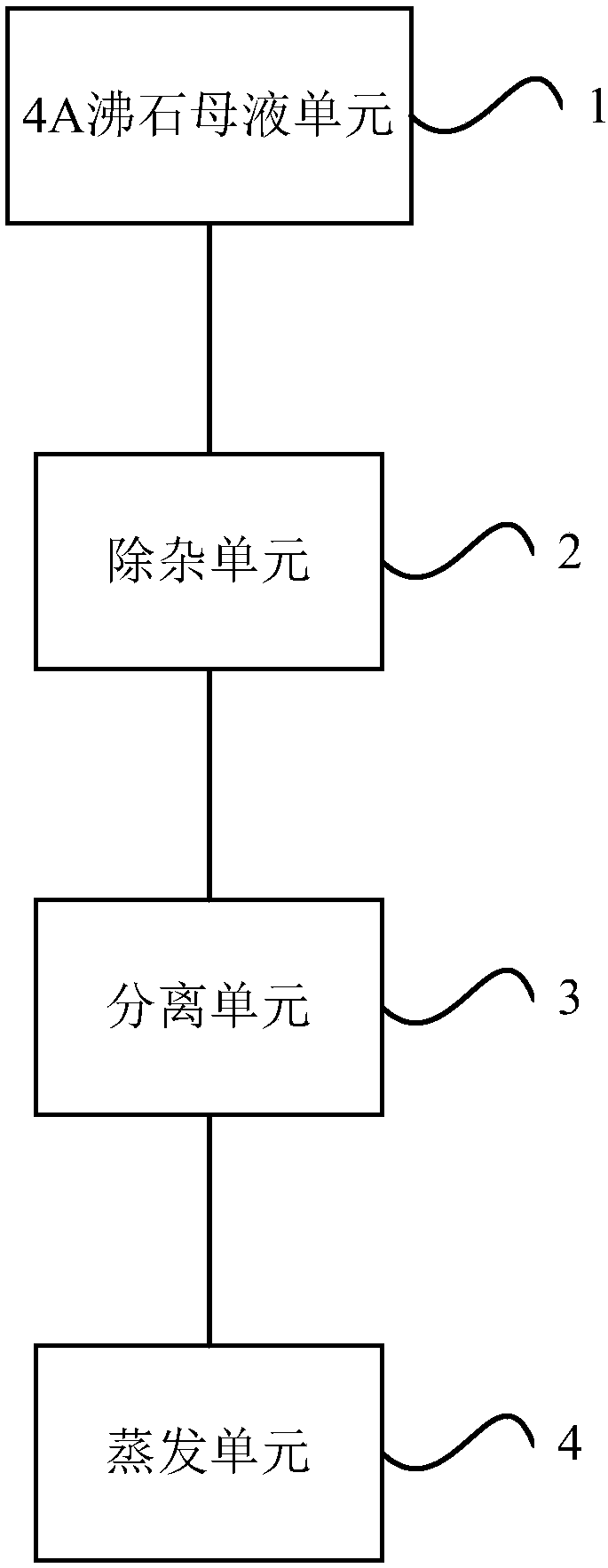

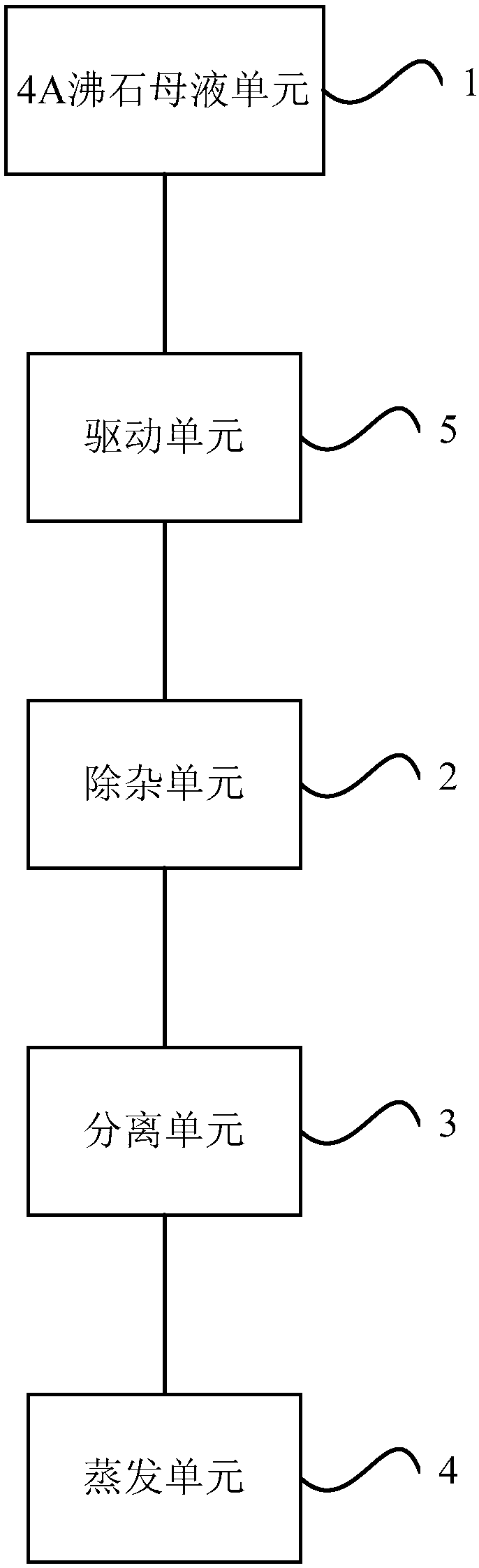

Method used

Image

Examples

Embodiment 1

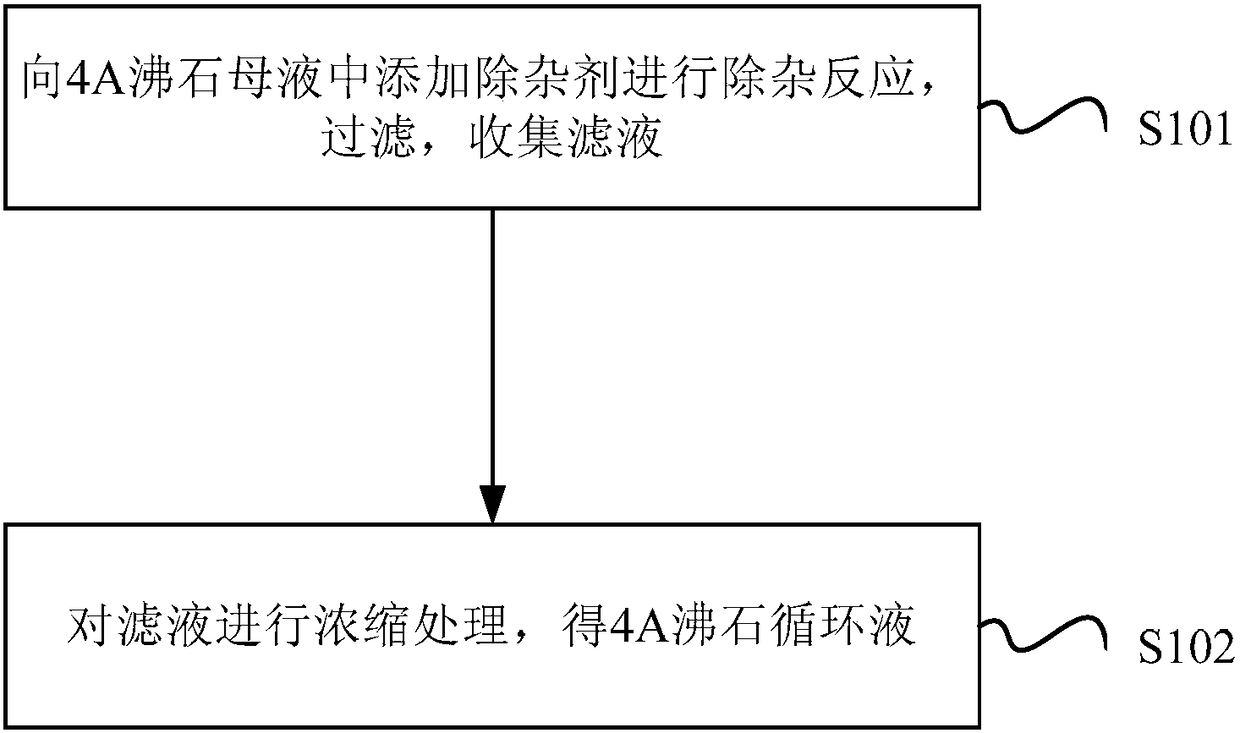

[0080] The recovery method of the 4A zeolite mother liquor of the present embodiment comprises the steps:

[0081] 1) Take 300ml 4A zeolite mother liquor and directly mix it with 15.15ml impurity remover to carry out impurity removal reaction. The temperature of the 4A zeolite mother liquor itself is 48°C. After 0.5 hours, filter the reaction system to obtain the filtrate;

[0082] The impurity remover is milk of lime with an effective calcium concentration of 154.68g / L;

[0083] And the ratio of the molar value of calcium oxide in the milk of lime to the sum of the molar value of aluminum oxide and silicon oxide in the 4A zeolite mother liquor is 3.5:1;

[0084] After testing, the 4A zeolite mother liquor is composed of substances with the following concentrations:

[0085] N T :60.65g / L;

[0086] Nk:48.82g / L;

[0087] Nc:11.83g / L;

[0088] Al 2 o 3 :3.42g / L;

[0089] SiO 2 :0.38g / L;

[0090] After testing, the filtrate is composed of substances with the following c...

Embodiment 2

[0098] The recovery method of the 4A zeolite mother liquor of the present embodiment comprises the steps:

[0099] 1) Take 300ml of 4A zeolite mother liquor and directly mix it with 2.85g of impurity remover to carry out impurity removal reaction. The temperature of the 4A zeolite mother liquor itself is 46°C. After 1 hour, filter the reaction system to obtain the filtrate;

[0100] The impurity remover is quicklime with 86.23% effective calcium;

[0101] And the ratio of the molar value of calcium oxide in quicklime to the sum of the molar value of alumina and silicon oxide in the 4A zeolite mother liquor is 4.0:1;

[0102] After testing, the 4A zeolite mother liquor is composed of substances with the following concentrations:

[0103] N T :58.37g / L;

[0104] Nk:46.29g / L;

[0105] Nc:12.08g / L;

[0106] al 2 o 3 :3.15g / L;

[0107] SiO 2 :0.34g / L;

[0108] After testing, the filtrate is composed of substances with the following concentrations:

[0109] N T :54.27g / L; ...

Embodiment 3

[0116] The recovery method of the 4A zeolite mother liquor of the present embodiment comprises the steps:

[0117] 1) Take 300ml of 4A zeolite mother liquor and directly mix it with 4g of impurity remover to carry out impurity removal reaction. The temperature of the 4A zeolite mother liquor itself is 44°C. After 2 hours, filter the reaction system to obtain the filtrate;

[0118] The impurity remover is calcium carbide slag with 68.93% effective calcium;

[0119] And the ratio of the calcium oxide molar value in the carbide slag to the sum of the alumina and silicon oxide molar values in the 4A zeolite mother liquor is 4.5:1;

[0120] After testing, the 4A zeolite mother liquor is composed of substances with the following concentrations:

[0121] N T :58.37g / L;

[0122] Nk:46.29g / L;

[0123] Nc:12.08g / L;

[0124] al 2 o 3 :3.15g / L;

[0125] SiO 2 :0.34g / L;

[0126] After testing, the filtrate is composed of substances with the following concentrations:

[0127] N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com