Ammonia-soda process mother liquid distillation tower scaring-proof method

A distillation tower and ammonia-alkali process technology, applied in the field of anti-scalding of ammonia-alkali process mother liquor distillation tower, can solve the problems of increased power consumption, unsatisfactory effect, low investment and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

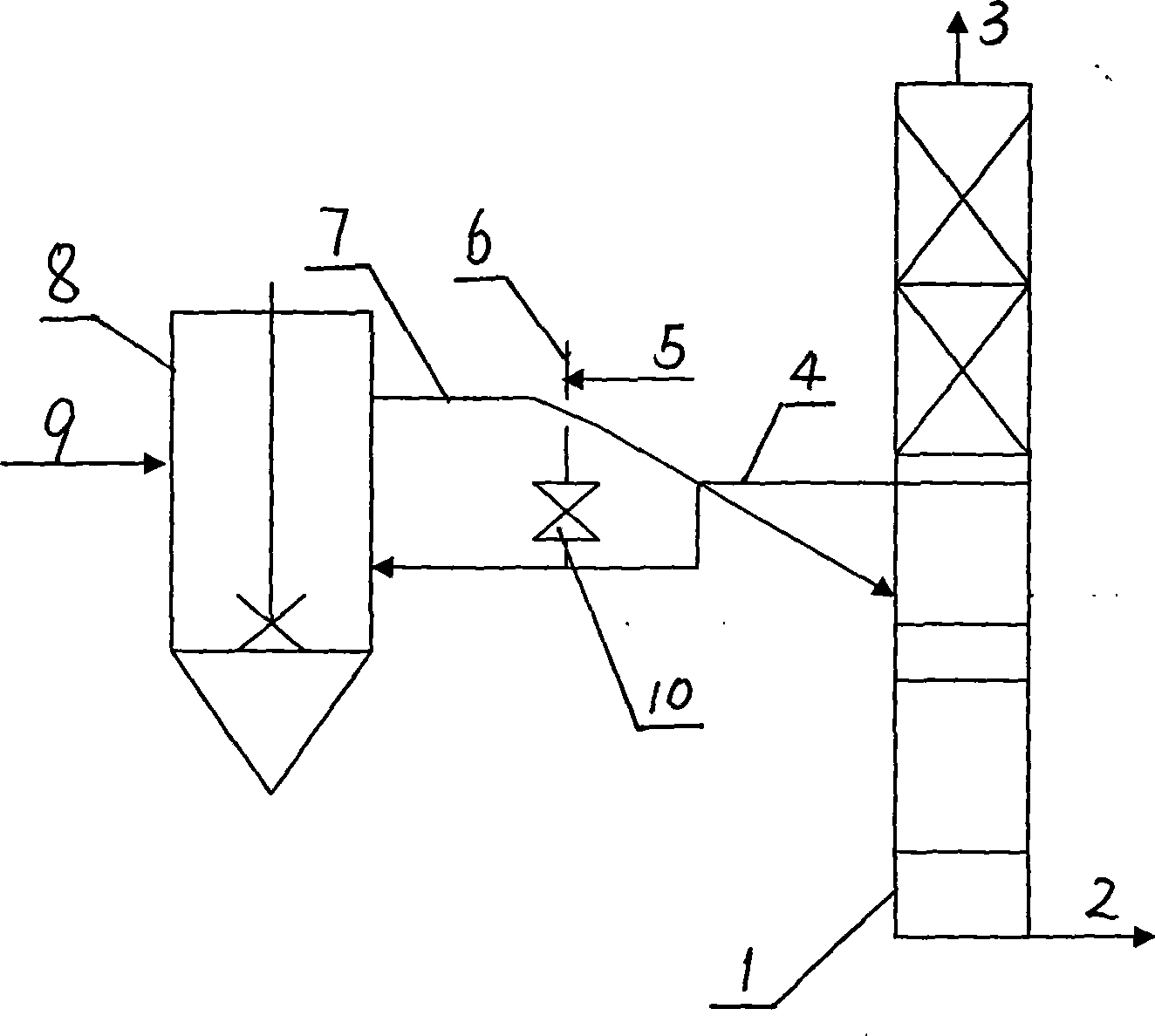

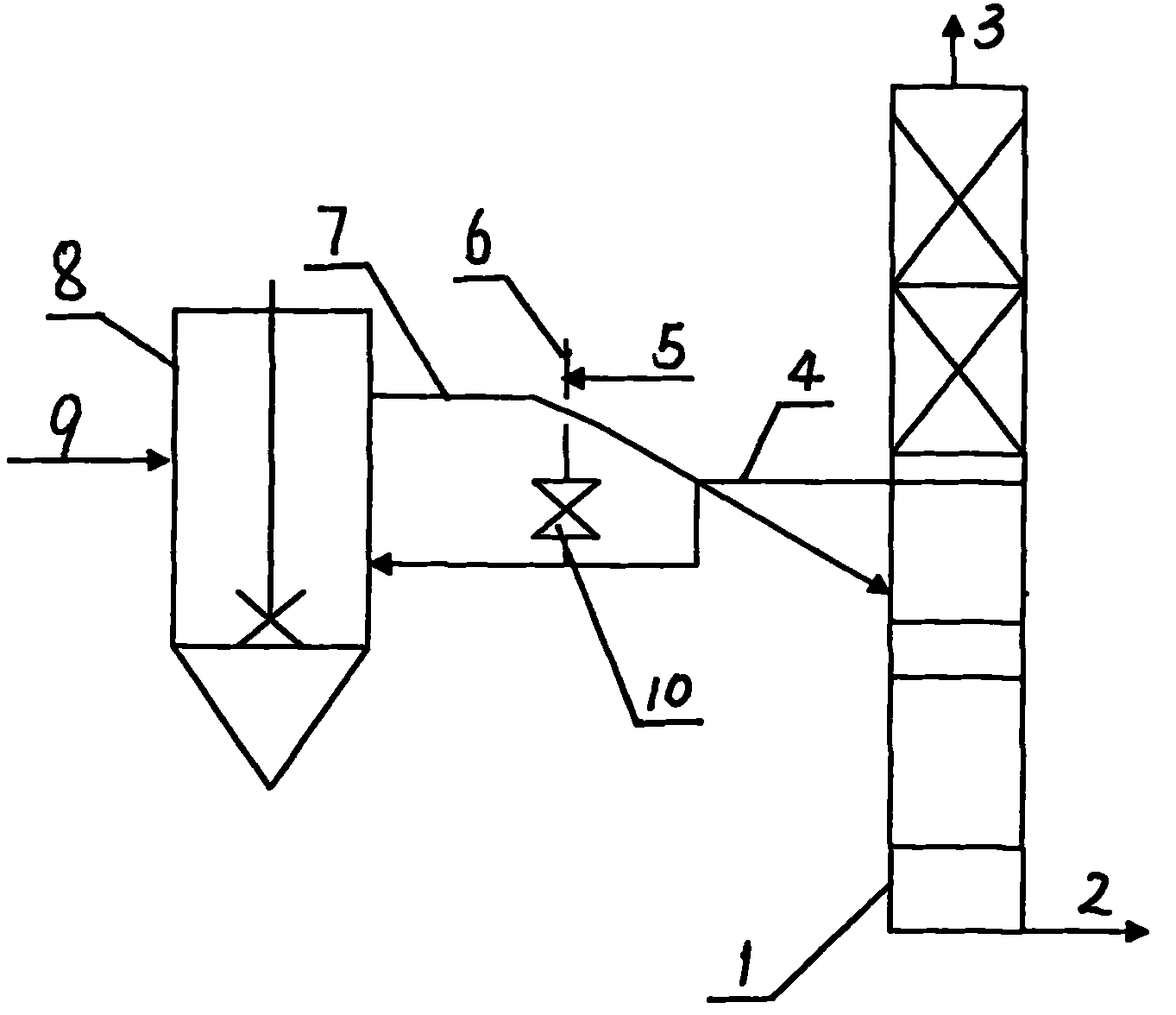

[0008] Refer to attached figure 1 , the embodiment of the present invention is as follows:

[0009] The present invention includes a distillation tower 1 and a pre-ash bucket 8 , one end of the preheating mother liquid pipe 4 communicates with the distillation tower 1 , and the other end communicates with the pre-ash bucket 8 . One end of the blending liquid pipe 7 communicates with the pre-ash bucket 8 , the other end communicates with the distillation tower 1 , and the condensate pipe 6 communicates with the preheating mother liquid pipe 4 . The anti-scarring method of the distillation tower is: after the distillation tower 1 is turned on, the temperature of the preheated mother liquor in the distillation tower 1 should be kept at 95°C. Enter the small valve 10 of the preheating mother liquor pipe, and the condensate is metered with a flow meter or equipped with a thin tube of a certain diameter to ensure that the amount added is within the specified range. The flow rate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com