Method for slowing down scarring speed of evaporator

An evaporator and scarring technology, which is applied in the field of slowing down the speed of evaporator scarring, can solve the problems of affecting the operating efficiency of the evaporator, a large amount of crystallization, and accelerated precipitation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

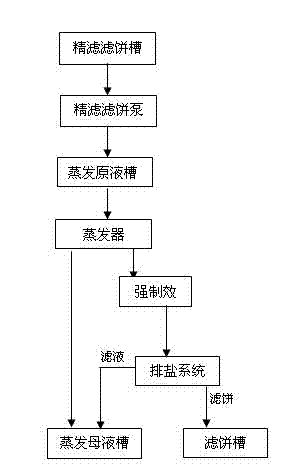

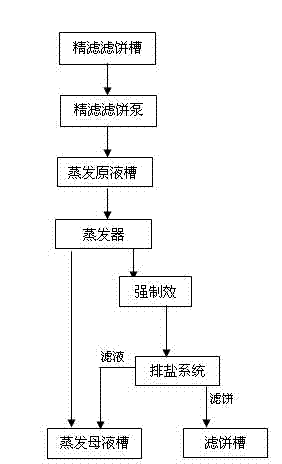

Image

Examples

Embodiment 1

[0012] Components of the evaporated stock solution: total alkali: 180.1g / l alumina: 87.33g / l caustic: 162.0g / l silicon oxide: 1.375g / l Rp: 0.539 silicon content index: 63.5. The amount of the fine filter cake is added at 4g / l, reacted in a water bath at 70°C for 1 hour, and evaporated after desiliconization The composition of the stock solution: total alkali: 183.30g / l alumina: 88.3g / l caustic alkali: 165.0g / l oxidation Silicon: 1.005g / l Rp: 0.535 Silicon content index: 87.9, silicon content index increased by 24.2.

Embodiment 2

[0014] Components of the evaporated stock solution: total alkali: 180.1g / l alumina: 87.33g / l caustic: 162.0g / l silicon oxide: 1.375g / l Rp: 0.539 silicon content index: 63.5. The amount of the fine filter cake is added at 10g / l, reacted in a water bath at 80°C for 2 hours, and evaporated after desiliconization The composition of the stock solution: total alkali: 193.0g / l alumina: 88.09g / l caustic alkali: 169.4g / l oxidation Silicon: 0.926g / l Rp: 0.520 Silicon content index: 95.1, silicon content index increased by 31.6.

Embodiment 3

[0016] Components of the evaporated stock solution: total alkali: 180.1g / l alumina: 87.33g / l caustic: 162.0g / l silicon oxide: 1.375g / l Rp: 0.539 silicon content index: 63.5. The amount of the fine filter cake is added at 30g / l, and it is reflected in a water bath at 90°C for 3 hours. After desiliconization, the original solution is evaporated. Components of the original solution: total alkali: 207.8. Silicon oxide: 0.597g / l Rp: 0.506 Silicon content index: 156.0, silicon content index increased by 92.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com