Dehydration method for reducing water content of sludge in microbial fermentation way

A technology of microbial fermentation and moisture content, applied in biological sludge treatment, sludge treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problems of high energy consumption and high investment, save machinery investment and operating costs, Conducive to the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

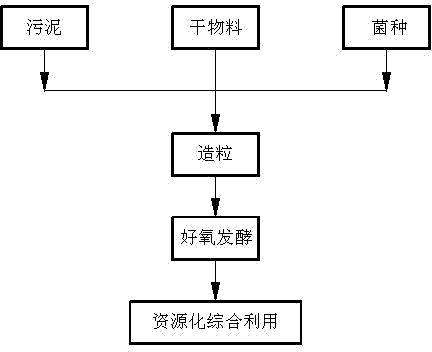

[0030] Such as figure 1 As shown, the dehydration method that utilizes microbial fermentation provided by the present invention to reduce the moisture content of sludge mainly includes two steps of granulation and fermentation, specifically set forth as follows:

[0031] (1) Material mixing and granulation and bacteria dosing

[0032] Taking the preparation of 100kg of granular sludge for fermentation as an example, after turning on the disc granulator, first add 55kg of lumpy sludge (moisture content 75%~80%) from the urban domestic sewage treatment plant to the disc granulator In the process, after the sludge is added, the dry material and crushed straw are added at a mass ratio of sludge: dry material: straw of 0.55:0.35:0.10, that is, the amount of dry material added is 35kg, and the amount of straw added It is 10kg. The dry material is sludge with a moisture content of 30% after drying, and the straw is crushed wheat straw, and the particle size of the crushed straw is ...

Embodiment 2

[0049] The dehydration method used in this example to reduce the moisture content of the sludge by microbial fermentation is the same as in Example 1, and the granulation process is the same, the difference lies in the material ratio and the aerobic fermentation method of the heap. The specific differences and the experimental process are as follows:

[0050] The mixing ratio of each material used in this embodiment is as follows:

[0051] According to the mass ratio, sludge: dry material: straw quality = 0.50:0.40:0.10, and the dosage of composite strain BYM is 0.25%. The dry material used the granular sludge finally prepared in Example 1 after multiple batches of fermentation.

[0052] This embodiment adopts the static stacking fermentation method. After granulation, the granular sludge is about 30t, and it is statically stacked. The pile body is conical and the height is 3m. There is a ventilation pipe at the bottom of the pile body, and a temperature measuring device is bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com