Method for matter and phase divided resource recovery of sludge

A technology of resource recovery and sludge, applied in sludge treatment, biological sludge treatment, pyrolysis treatment of sludge, etc., can solve the problem of insufficient sludge carbon source and resource recovery, large volume of mixed digestion reactor, and sludge weariness. Oxygen digestion efficiency is low and other problems, to achieve the effect of saving heating energy consumption, shortening residence time, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

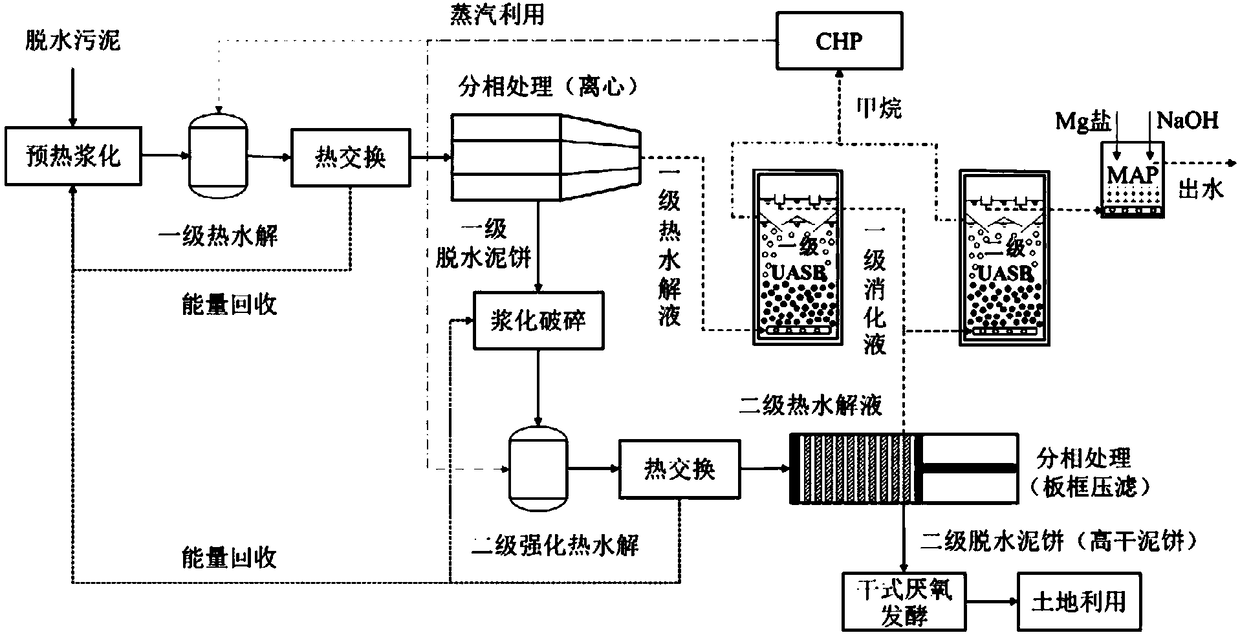

[0036] The specific implementation method is: the dewatered sludge with a solid content rate of 15-30% in the sewage plant first utilizes hydrolysis to release steam and heat exchange to recover energy to preheat the dewatered sludge to obtain pulped sludge (80-30%) 90°C), after slurry treatment, the sludge viscosity was significantly reduced. The pulped sludge is then pumped into the first-level thermal hydrolysis pretreatment system (160-165°C, 10-30min) for the first-level thermal hydrolysis pretreatment to form the first-level thermal hydrolysis sludge, which promotes the synthesis of proteins in the sludge flocs. A large amount of organic matter such as polysaccharides is dissolved, and then heat exchange treatment is performed. After the temperature of the first-level thermal hydrolysis sludge drops to 80-90°C, the thermal hydrolysis sludge is solid-liquid treated by direct centrifugation without adding chemicals. Separation to form primary dewatered cake and primary the...

Embodiment 1

[0040] The solid content TS of dewatered sludge in urban sewage treatment plants is 18%, VS / TS is about 70%, and diluted with water to a solid content rate of 15%, hot water can be decompressed and steam can heat the feed sludge to about 85°C. After 2 hours of slurry treatment, the viscosity of the sludge can be reduced to less than 1 / 10 of the original sludge. The slurry sludge enters the first-stage thermal hydrolysis reactor. The thermal hydrolysis temperature is 160°C, and the time is 30 minutes. The temperature of the thermal hydrolysis sludge is reduced. Centrifugal dehydration is carried out directly without adding drugs at 80°C, the solid content of the mud cake is about 30%, and the SCOD of the first-grade thermal hydrolyzate can reach 70000mg / L. Adding water to the dehydrated cake is crushed by high-speed stirring, the crushing speed is about 30,000rpm, and the slurry is treated with thermal hydrolysis steam. The solid content of the pulped sludge is about 20%. The t...

Embodiment 2

[0042] The solid content TS of the dewatered sludge of the urban sewage treatment plant is 22%, and the VS / TS is about 55%. It is diluted with water to a solid content rate of 16%. The hot water can be used to decompress the steam to heat the feed sludge to about 85°C. After 2 hours of slurry treatment, the viscosity of the sludge can be reduced to less than 1 / 10 of the original sludge. The slurry sludge enters the first-stage thermal hydrolysis reactor. The thermal hydrolysis temperature is 160°C, and the time is 30 minutes. The temperature of the thermal hydrolysis sludge is reduced. Centrifugal dehydration is carried out directly without adding drugs at 80°C, the solid content of the mud cake is 35%, and the SCOD of the first-grade thermal hydrolyzate can reach 45000mg / L. Adding water to the dehydrated cake is crushed by high-speed stirring, the crushing speed is about 30,000rpm, and the slurry is treated with thermal hydrolysis steam. The solid content of the pulped sludge ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com