Combined technique of hydrotreating and delay coking of residual oil

A hydrotreating and delayed coking technology, applied in hydrotreating process, petroleum industry, treating hydrocarbon oil, etc., can solve the problem of no specific combination, and achieve the effect of reducing energy, saving investment cost and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

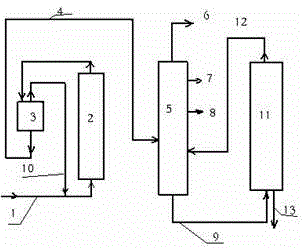

[0026] This embodiment adopts the fluidized bed residual oil hydrotreating-delayed coking method provided by the present invention, and the process is shown in figure 1 , that is, the residual oil undergoes a hydrogenation reaction in a hydrotreating unit, and the reaction product is separated to obtain gas and residual oil hydrogenation liquid phase components. The obtained residual oil hydrogenation liquid phase components enter the delayed coking fractionation tower to separate different fractions. The products are gas, gasoline, diesel oil, and the fractions above the wax oil include hydrogenated wax oil and heavy oil and coker wax oil and heavy oil, which are recycled to Coke tower for processing. Table 1, Table 2, and Table 3 are the properties of raw oil, process conditions and test results, respectively.

[0027] Table 1 Properties of raw materials

[0028] project Residue raw material Liquid Phase Components of Ebullating Bed Residue Hydrogenation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com