Patents

Literature

42results about How to "Avoid the reverse reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

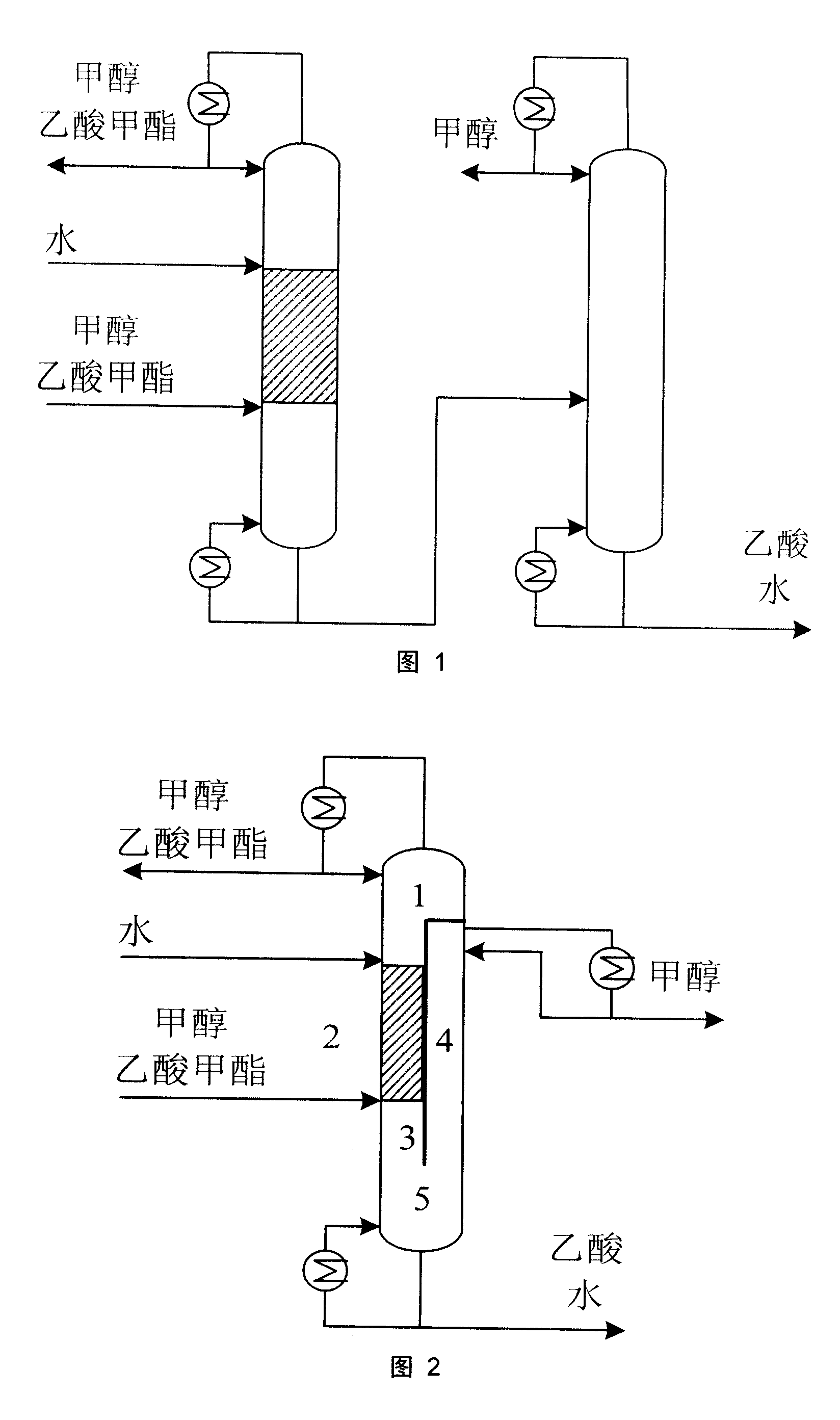

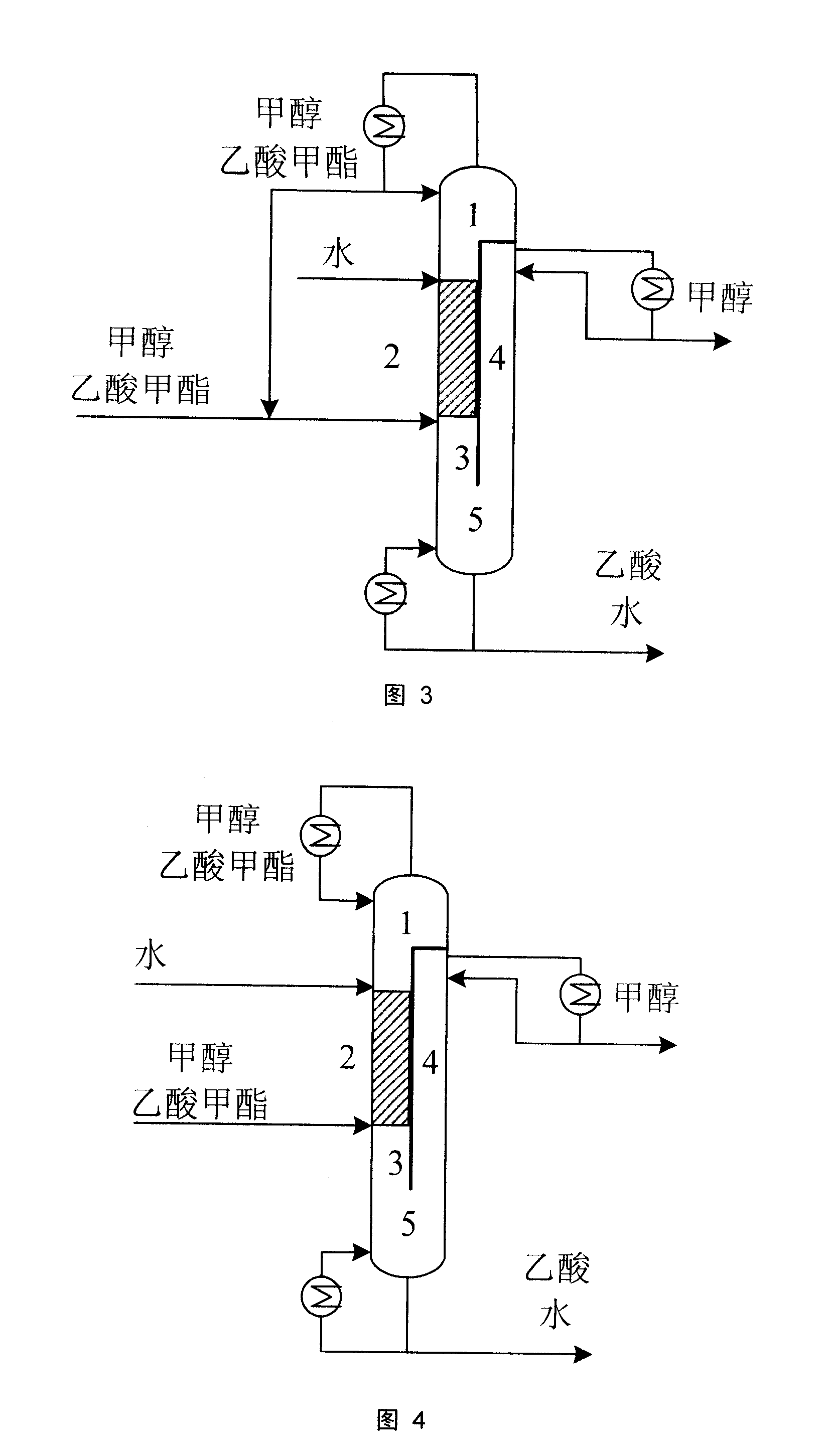

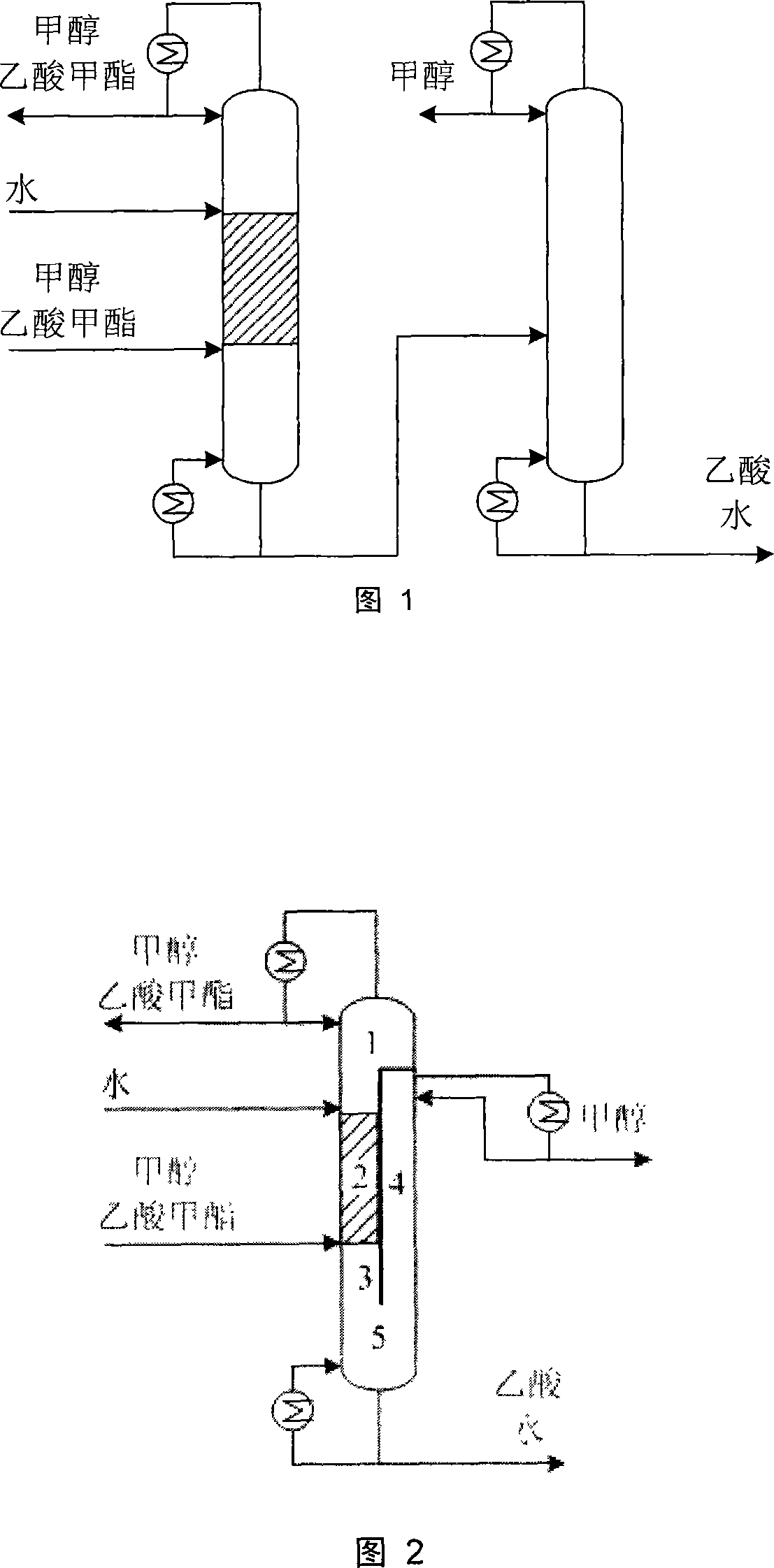

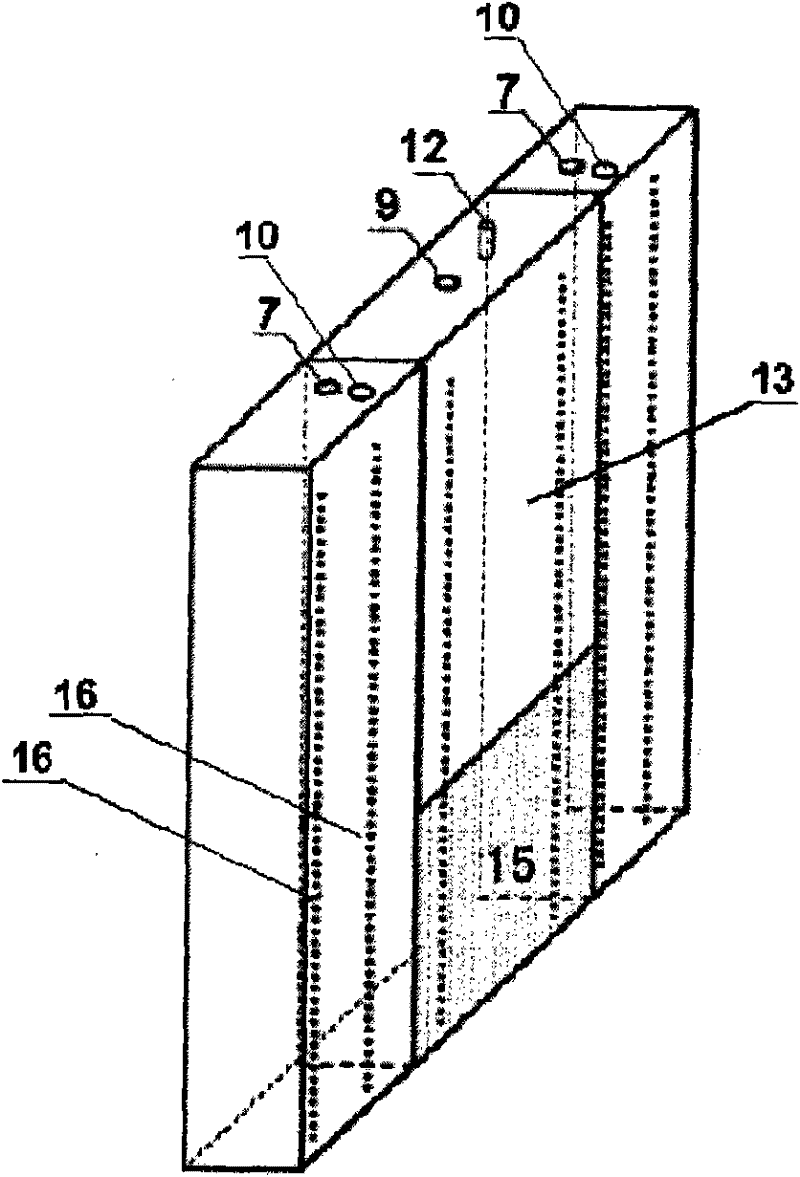

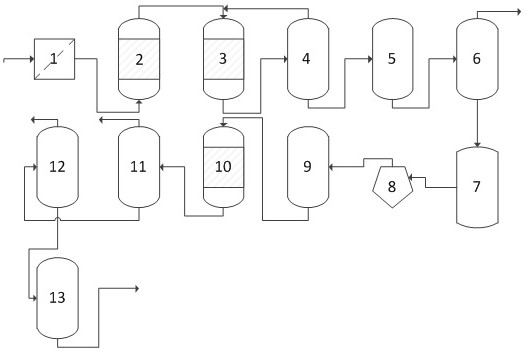

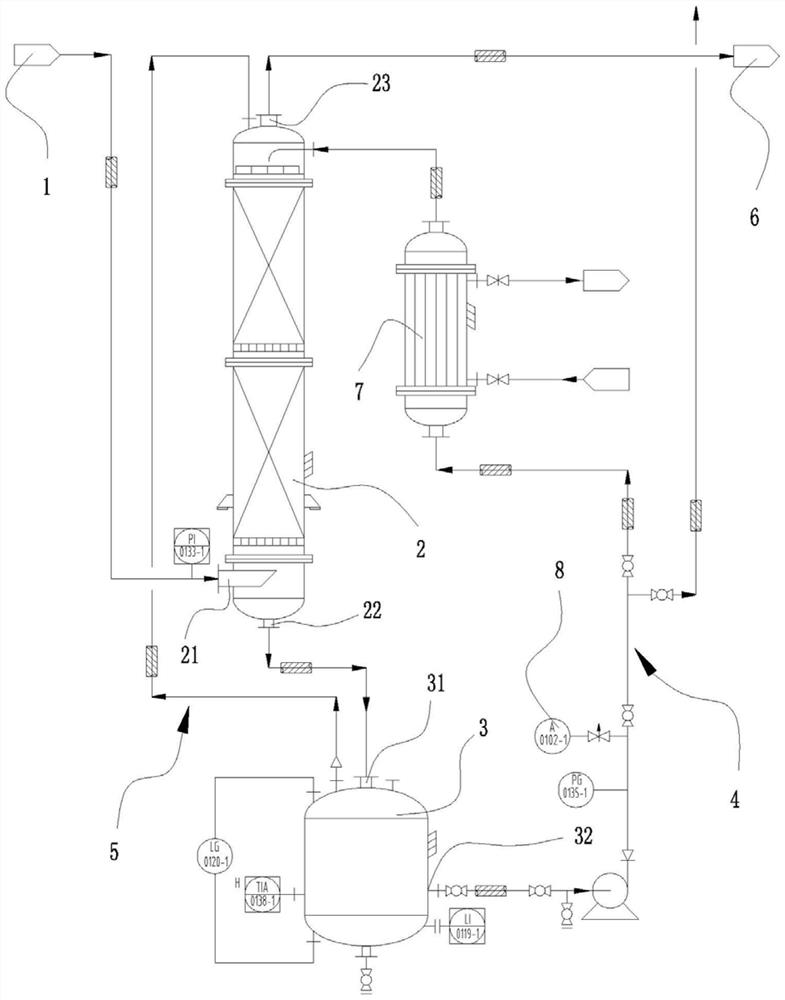

Hydrolyzation separation apparatus for methyl acetate and technique

InactiveCN101244982AIncrease hydrolysis rateAvoid remixingOxygen-containing compound preparationOrganic compound preparationSide effectDistillation

The invention provides a hydrolyzing and separation device of methyl acetate and a technique method thereof, which more particularly relates to a novel technique to catalyze and hydrolyze methyl acetate by a reaction bulkhead distillation tower, which can organically combine reaction process, product separation and recovery of no reactant into the tower. A separator extending from the upper part of the tower to the lower part of the tower is arranged on the vertical direction in the conventional distillation tower, the upper part of one side of which is covered and the other side of which is filled with a catalyst; therefore, the inner space of the reaction bulkhead distillation tower is divided into five regions with different functions. The hydrolyzing and separation device of methyl acetate can fully unleash the advantage of bulkhead tower and reaction distillation, and can cause hydrolysis reaction, product separation and recovery of non reactant to be realized in the same tower. The device provided by the invention and the technique process thereof can obtain the methyl acetate with 60 percent to 99.99 percent hydrolysis rate and products with high purity, restrain side effect effectively, reduce the volume of equipment markedly, simplify process, and reduce energy consumption and operation cost.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

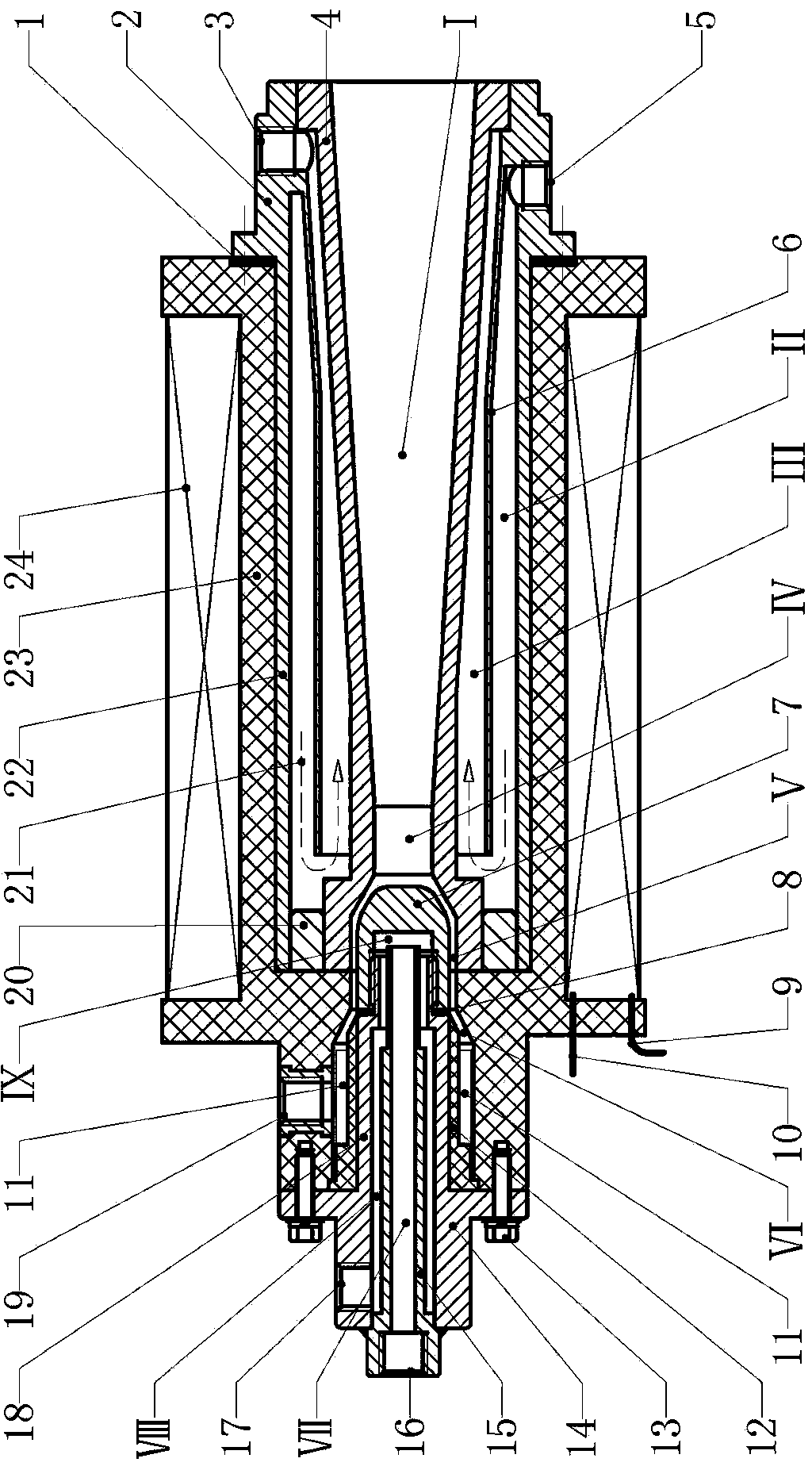

Plasma torch for dielectric heating

ActiveCN103906337AEasy to installAvoid parasitic arcingPlasma techniqueEcological environmentHydrogen

The invention provides a plasma torch for dielectric heating, and relates to plasma equipment. The plasma torch is mainly composed of a front torch body, an anode, a rear torch body, a cathode and an insulation frame. The front torch body is provided with a guide sleeve and a cylinder extending backwards, and the guide sleeve is arranged in the inner space of the cylinder; the anode is embedded into the front torch body, the space between the cylinder of the front torch body and the wall of the anode forms a cooling water jacket, a cathode base is arranged on a rotary body structure of the rear torch body, the cathode is installed at the front end of the cathode base, and a cooling cavity is formed in the cathode. The front torch body is installed at the front end of the insulation frame, the extending cylinder of the front torch body is inserted into a front inserting port of the insulation frame, the rear torch body is installed at the rear end of the insulation frame, the cathode base on the rear torch body enters a rear inserting port of the insulation frame, the head of the cathode stretches into a cylindrical space in the rear portion of the anode, and the space between the head of the cathode and the wall of the rear portion of the anode forms an ionization channel. The plasma torch is used for pyrolyzing water to manufacture hydrogen or used for processing harmful substances, thereby reducing the dependence on coal and oil of people and preserving the ecological environment.

Owner:JIANGSU YAFENG ALLOY MATERIAL

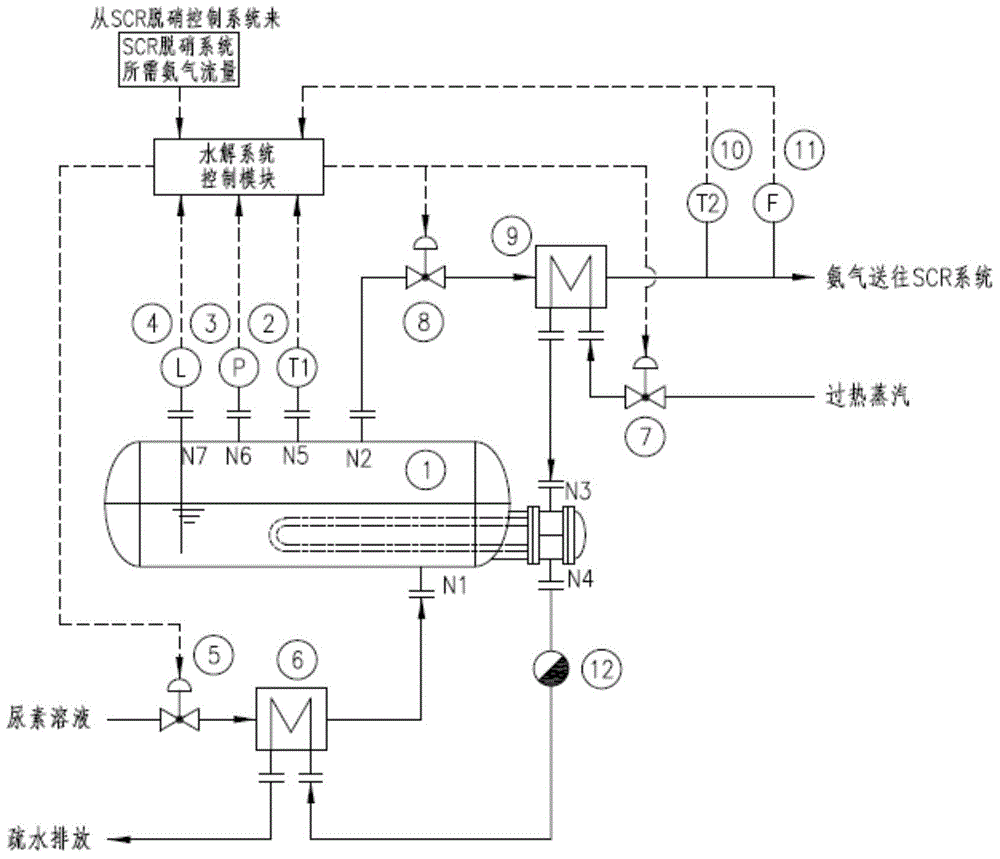

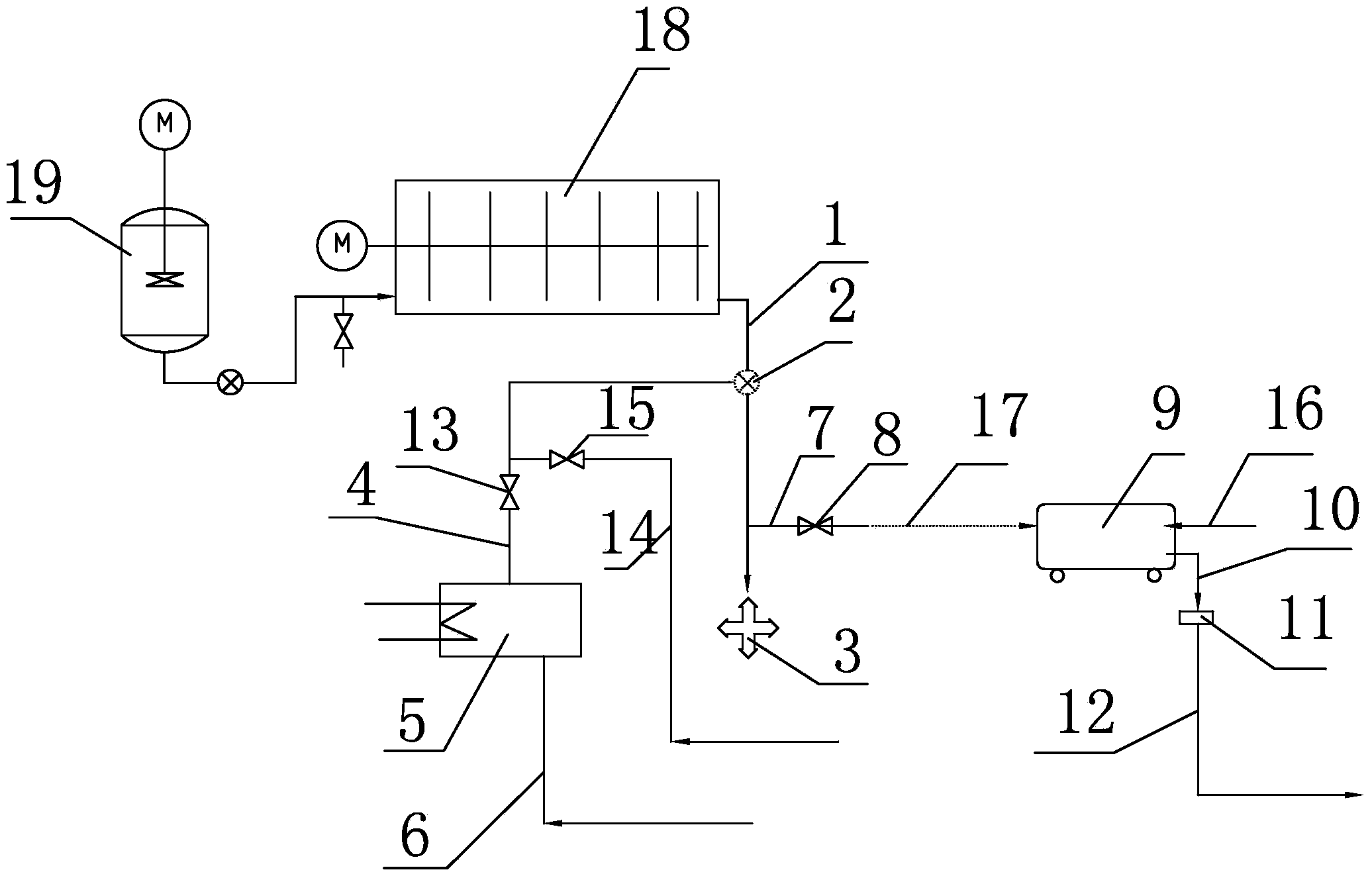

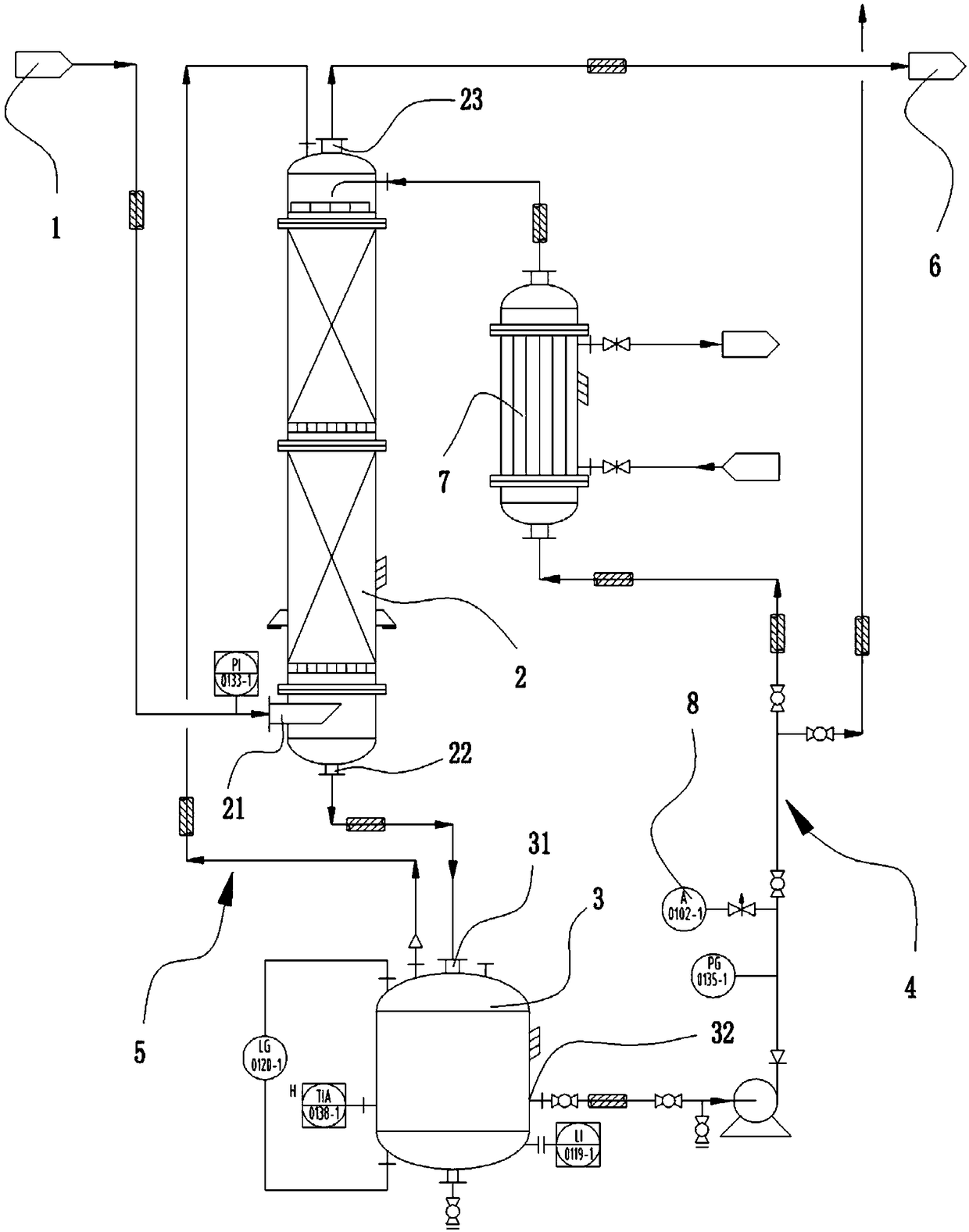

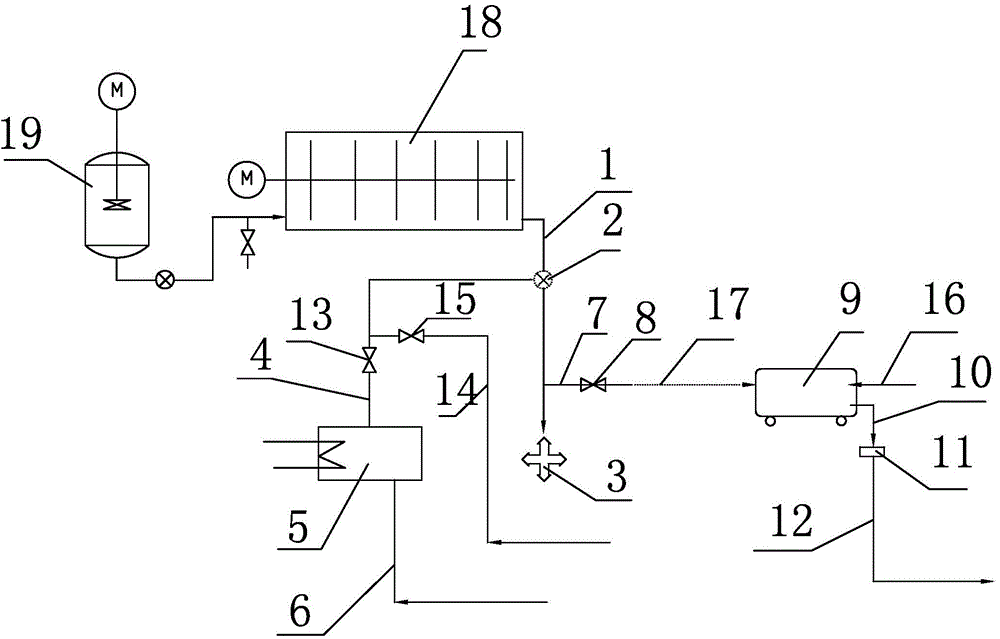

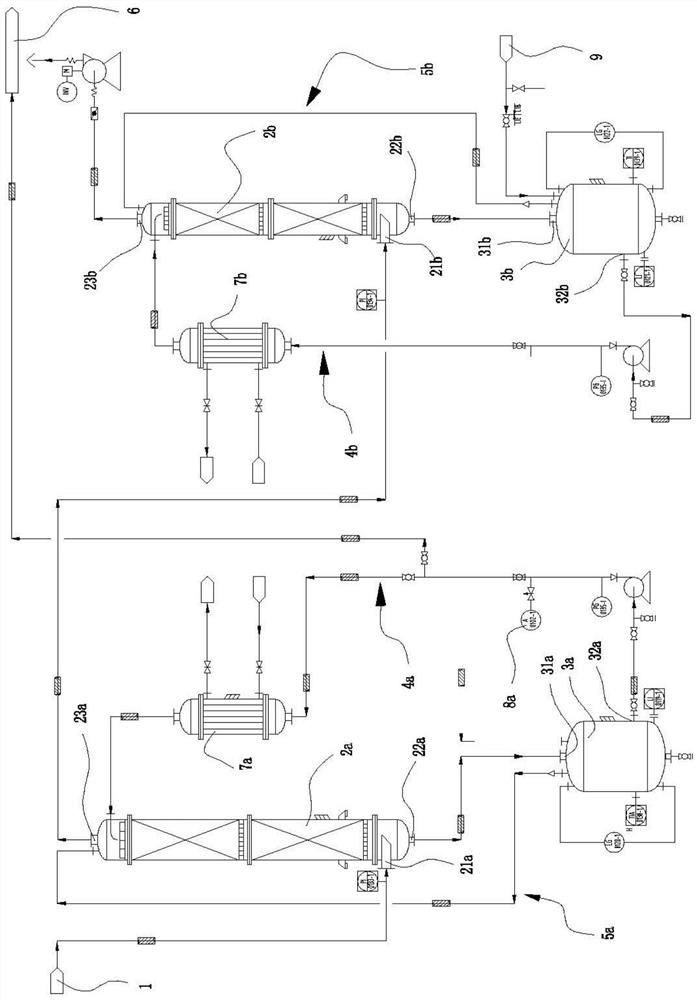

System and control method for producing ammonia gas by hydrolyzing urea solution

InactiveCN103979575ARaise the inlet temperatureImprove utilization efficiencyAmmonia preparation/separationProcess engineeringHydrolysis

The invention discloses a system for producing ammonia gas by hydrolyzing a urea solution. The system comprises a hydrolyzer, a hydrolyzer thermometer T1, a hydrolyzer pressure transmitter P, a hydrolyzer liquidometer L, a urea solution regulating valve A1, a hydrophobic heat exchanger, a steam regulating valve A2, a hydrolyzing gas outlet regulating valve A3, a steam heat exchanger, a hydrolyzing gas outlet thermometer T2, a hydrolyzing gas outlet flowmeter F, a steam hydrophobic valve and a hydrolysis system control module, wherein the hydrolyzer is provided with seven ports respectively connected with the components above; the hydrolysis system control module is respectively connected with the hydrolyzer thermometer T1, the hydrolyzer pressure transmitter P, the hydrolyzer liquidometer L, the urea solution regulating valve A1, the steam regulating valve A2, the hydrolyzing gas outlet regulating valve A3, the hydrolyzing gas outlet thermometer T2 and the hydrolyzing gas outlet flowmeter F through cables. The invention also discloses a control method for producing ammonia gas by hydrolyzing the urea solution, which is implemented through six steps. The system and control method disclosed by the invention are simple and reliable, and easy to control. Steam is taken as a heat source of a hydrolysis system, so that the operation cost and the energy consumption are reduced.

Owner:北京乐道致远技术有限公司

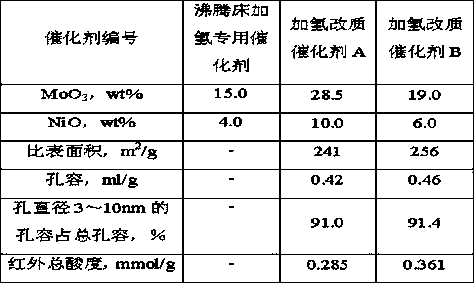

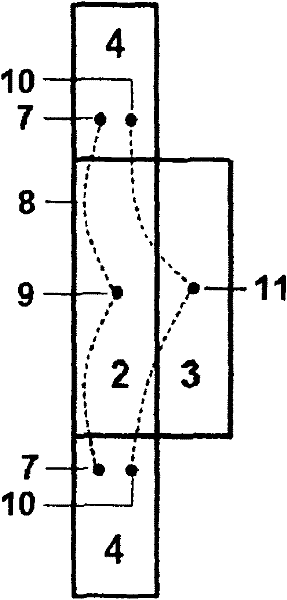

Hydrogenation method for regenerating waste lubricating oil,

ActiveCN105733793AAdvantages of multi-stage hydrogenationHigh yield utilizationTreatment with hydrotreatment processesLubricant compositionHydrogenFluidized bed

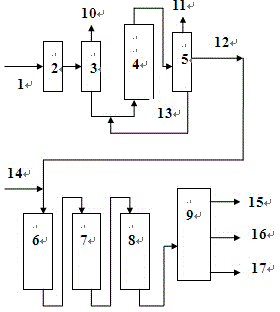

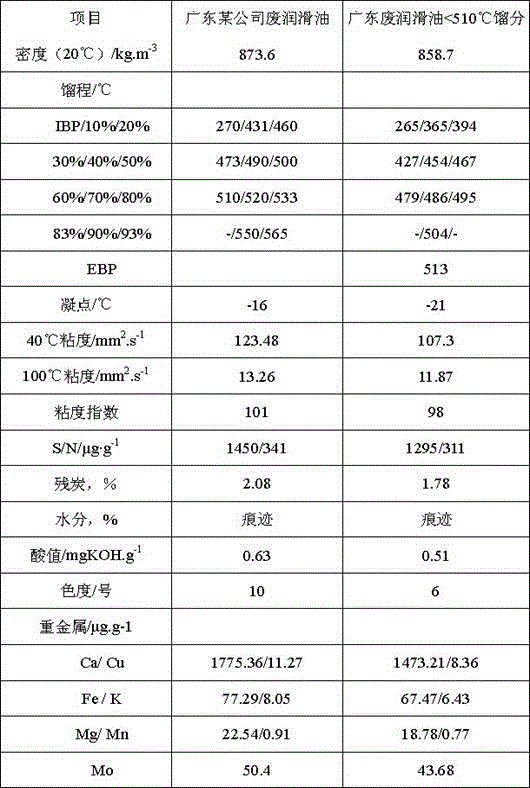

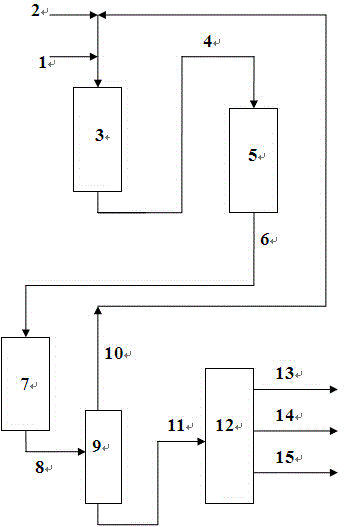

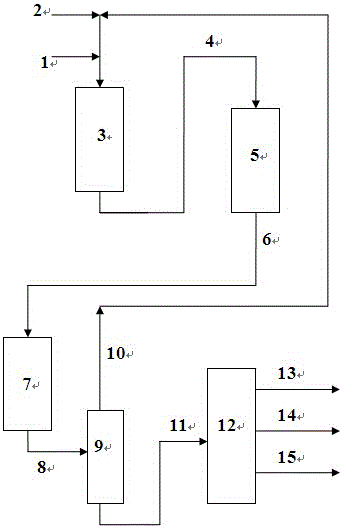

The present invention discloses a hydrogenation method for regenerating waste lubricating oil. The method includes the following steps: conducting electro-desalting on waste lubricating oil, sending the waste lubricating oil into a flash column, separating dissolving water and part of light oil, sending the bottom materials into a fluidized bed reactor, and conducting hydrogenation pretreatment reaction; separating reaction effluents, mixing an obtained liquid fraction with hydrogen, sending the mixture into a hydrotreating reaction zone, sending an effluent from the hydrotreating reaction zone into a hydrogenation modification reaction zone, sending a hydrogenation modification effluent into a hydrogenation supplement refining reaction zone, carrying out hydrogenation supplement refining reaction; and isolating the hydrogenation supplement refining products to obtain base oil for lubricating oil. Compared with the prior art, the method of the present invention can treat whole fraction of waste lubricating oil; the base oil product for lubricating oil has high yield and good quality; and the method can ensure a long-term stable operation of a device, and achieve efficient utilization of waste lubricating oil resources.

Owner:CHINA PETROLEUM & CHEM CORP +1

Device and method for cleaning pipelines for cationic polyester melts

InactiveCN103658121APrevent dehydration and carbonizationReach applied technologyChemical industryHollow article cleaningPolyesterFour-way valve

The invention discloses a device and a method for cleaning pipelines for cationic polyester melts. The device comprises a melt discharge pump; the melt discharge pump is mounted on a polyester melt discharge pipeline of a cationic polyester melt manufacturing device; the polyester melt discharge pipeline is connected with a melt four-way valve; the melt discharge pump is connected with a first pipeline; the first pipeline is connected with an electric heater; the electric heater is connected with a public engineering steam system by a second pipeline; a steam valve is mounted on the first pipeline; a nitrogen pipeline is mounted on the first pipeline between the steam valve and the melt discharge pump; a third pipeline is mounted on the polyester melt discharge pipeline between the melt discharge pump and the melt four-way valve; the third pipeline is connected with a cleaning collecting vehicle by a metal hose; a melt blow-off valve is mounted on the third pipeline; the cleaning collecting vehicle is connected with a cleaning waste liquid receiving device by a fourth pipeline. The device and the method have the advantages that the pipelines for the cationic polyester melts can be cleaned by the aid of the device and the method, equipment can be prevented from being corroded, energy can be saved, and environments can be protected.

Owner:浙江东华纤维制造有限公司

Preparation method of alpha-terpilenol

InactiveCN103044202AAvoid the reverse reactionHigh boiling pointOrganic compound preparationHydroxy compound preparationOrganic solventGas phase

The invention discloses a preparation method of alpha-terpilenol, which comprises the steps that firstly, alpha-pinene, water and an organic solvent are placed in a container, and subjected to heating reflux; evaporated vapor enters a rectifying tower; secondly, a gas-phase mixture from the top of the rectifying tower enters a condenser at the top end of the rectifying tower; a condensed liquid enters a packed tower, and hydrated by the catalysis of a solid acid catalyst to form alpha-terpilenol; and finally, a mixed liquid of the packed tower enters the container and is evaporated continuously; the evaporated vapor enters the rectifying tower and separated; alpha-terpilenol is left in the rectifying tower; and a gas phase mixture from the top end of the rectifying tower continuously enters the condenser. The preparation method adopts a rectification-coupling technology, and takes alpha-pinene as a raw material, performs alpha-pinene hydration directly, and produces alpha-terpilenol continuously, the yield of alpha-terpilenol is increased; the selectivity of alpha-terpilenol is improved; the production capacity is improved; the energy consumption and the production cost are lowered; and compared with the traditional technology, the automatization of a production process is easy to realize.

Owner:江苏宏邦化工科技有限公司

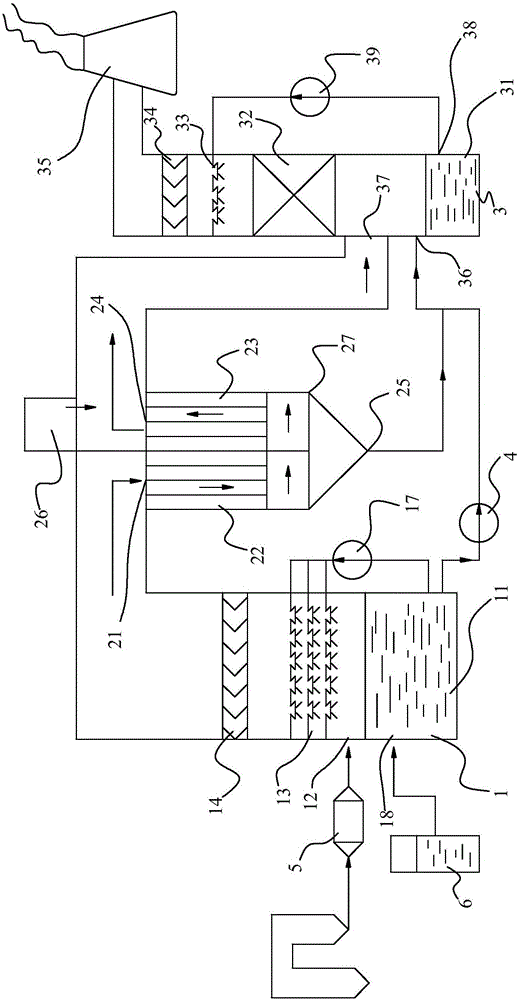

Twin-tower type flue gas deep purification device through plasma coupling and sodium based absorption and method thereof

ActiveCN105056723AEasy to handleImprove efficiencyLighting and heating apparatusDispersed particle separationEngineeringFlue gas

The invention discloses a twin-tower type flue gas deep purification device through plasma coupling and sodium based absorption. The desulfurization tower and denitration tower in the device are separated from each other. The desulfurization tower comprises a desulfurization slurry circulating tank, a desulfurization spraying layer, a desulfurization demister, and a desulfurization flue gas outlet from bottom to top. A plasma demisting and oxidizing device comprises a demisting part and an oxidizing part, and the lower ends of the demisting part and the oxidizing part are both provided with a demisting wastewater outlet. The denitration and demercuration tower comprises a denitration and demercuration slurry circulating tank, a filling material layer, a denitration and demercuration spraying device, a denitration and demercuration demister, and a denitration and demercuration flue gas outlet from bottom to top. A desulfurization flue gas outlet is arranged between the desulfurization slurry circulating tank and the desulfurization spraying layer. The denitration and demercuration slurry circulating tank is connected to the oxidizing part. The demisting part is connected to the desulfurization flue gas outlet. The desulfurization slurry circulating tank is connected to the desulfurization spraying layer. The denitration and demercuration slurry circulating tank is connected to the denitration and demercuration spraying device. The desulfurization slurry circulating tank and the demisting wastewater outlet are both connected to the denitration and demercuration slurry circulating tank.

Owner:ZHEJIANG FUCHUNJIANG ENVIRONMENTAL THERMOELECTRIC CO LTD +1

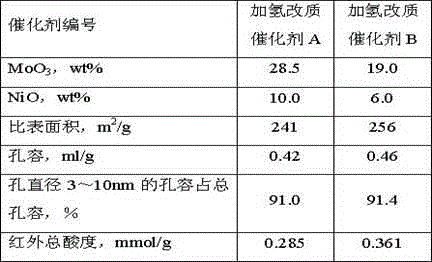

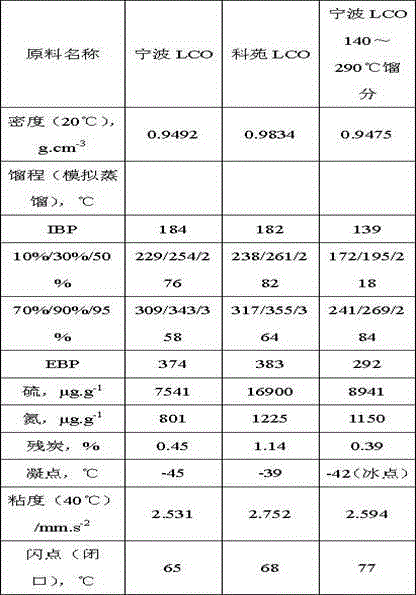

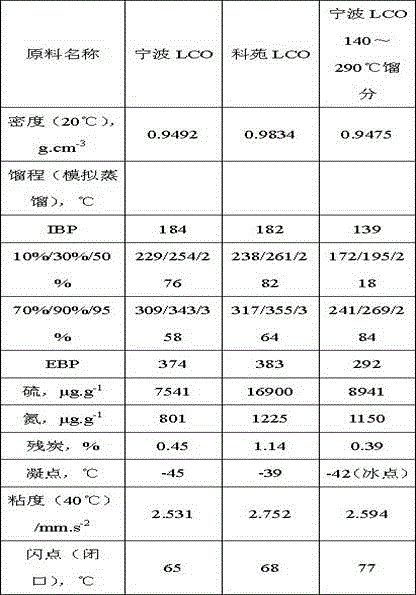

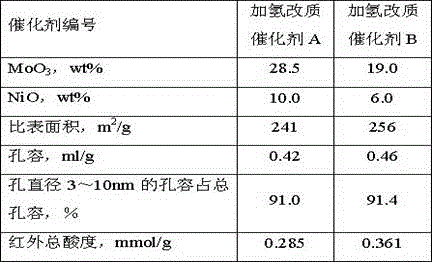

Hydrogenation process for FCC recycle oil

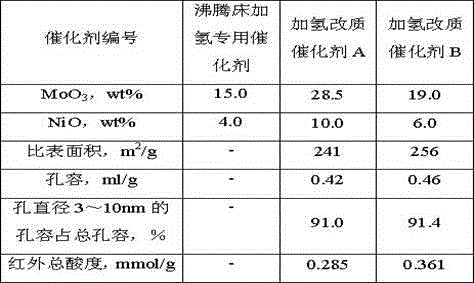

ActiveCN104593059ALow ring-opening activityGuaranteed Product YieldTreatment with hydrotreatment processesZeoliteAmorphous silicon

The invention discloses a hydrogenation process for FCC recycle oil. The method comprises the following steps that: after mixing of FCC recycle oil with hydrogen, the obtained mixture enters a hydro-treating reaction zone and sequentially contacts with a hydro-protecting catalyst, a hydrofining catalyst and a hydro-upgrading catalyst A for hydrogenation reaction; the effluent obtained after hydro-treatment enters a hydro-upgrading reaction zone where a hydro-upgrading catalyst B containing amorphous silicon aluminum and modified Y zeolite is used, and undergoes hydro-upgrading reaction in the presence of hydrogen; and the effluent obtained after hydro-upgrading enters a hydro-finishing reaction zone and undergoes hydro-finishing reaction, and hydro-finishing products are separated so as to obtain transformer oil. The hydrogenation processing method for FCC recycle oil provided by the invention uses FCC recycle oil as a raw material to produce transformer oil, so raw material sources of transformer oil products can be broadened and special oil products meeting higher quality requirements can be produced.

Owner:CHINA PETROLEUM & CHEM CORP +1

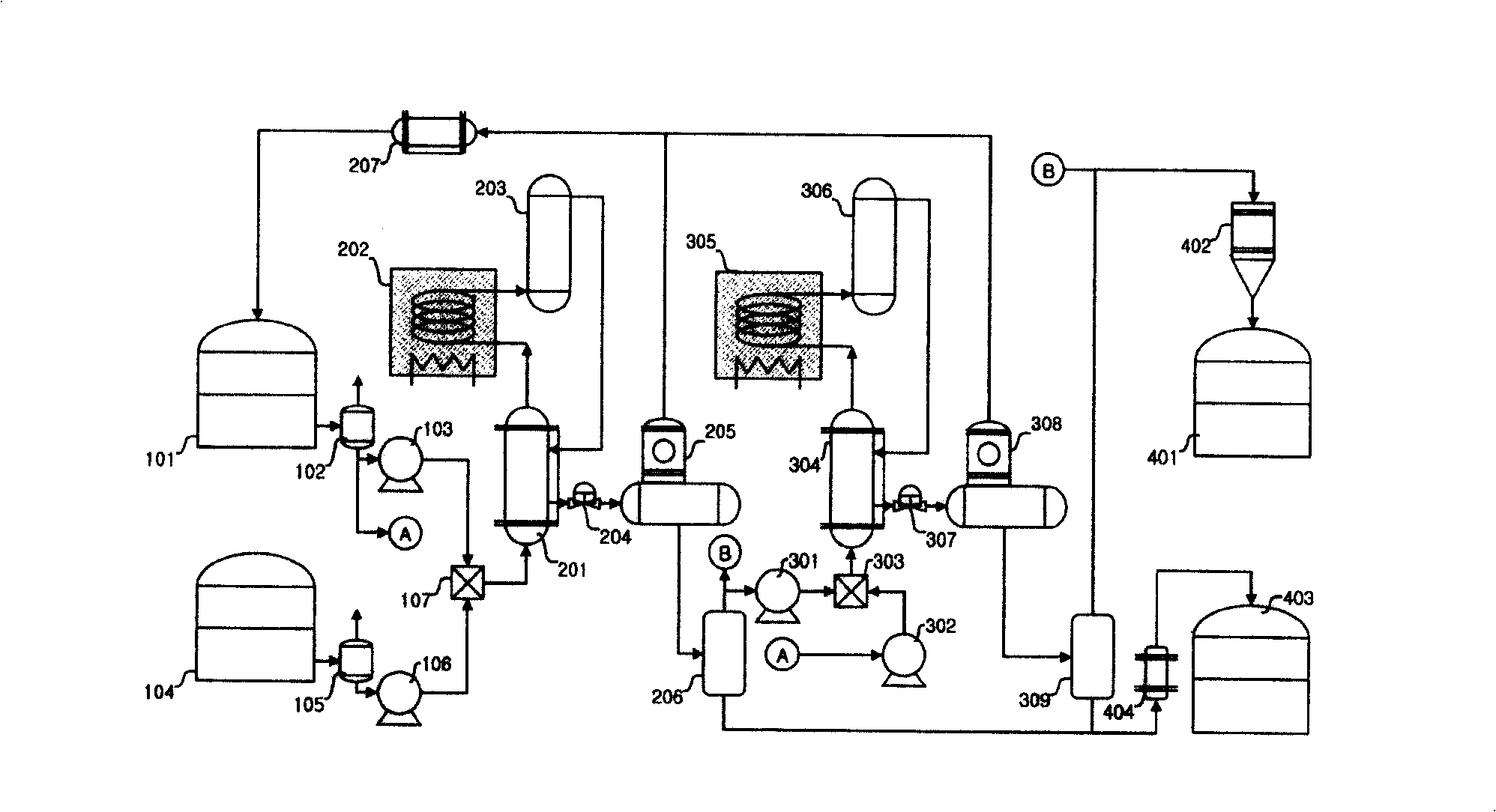

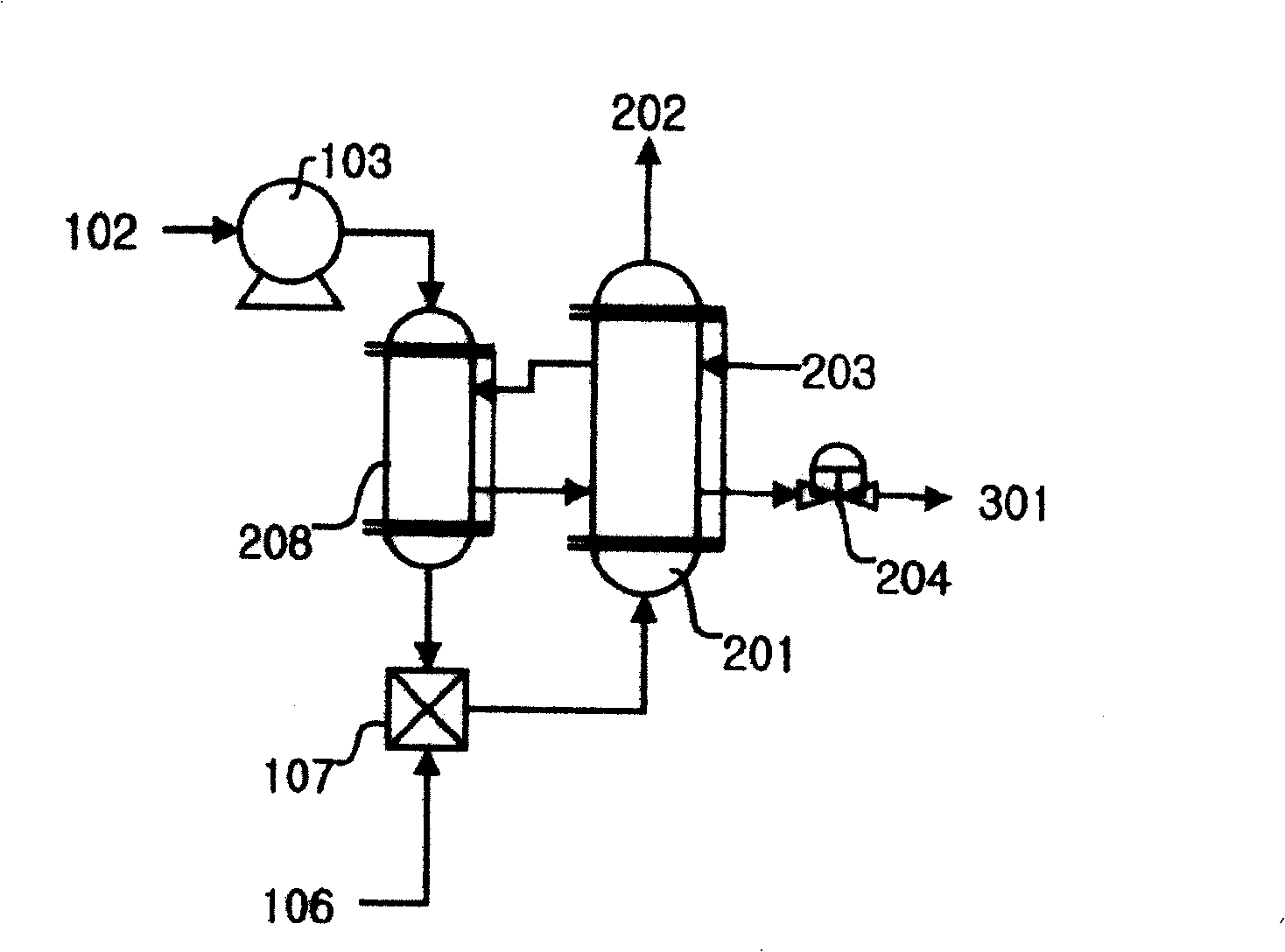

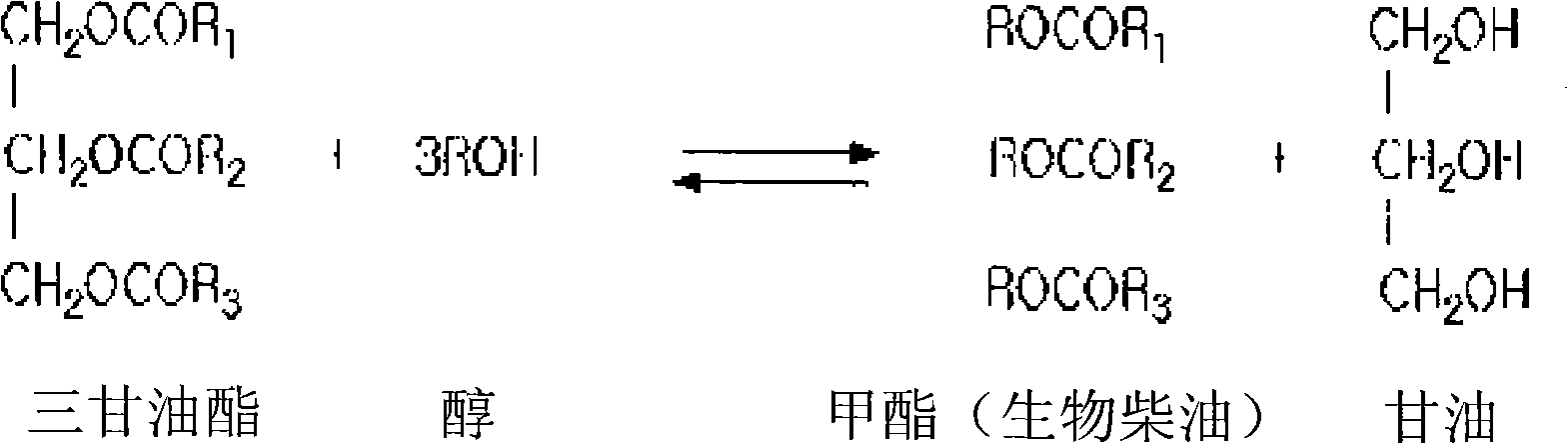

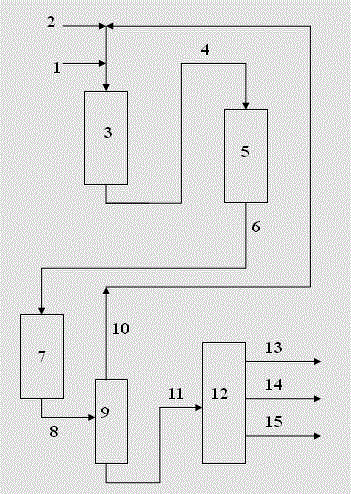

A method for producing biodiesel using supercritical alcohols

InactiveCN101331209AAvoid the reverse reactionLow costFatty acids production/refiningBiofuelsBiodieselVegetable oil

Disclosed herein is a method for producing biodiesel in the form of fatty acid alkyl ester by esterifying oils-and-fats, including animal or vegetable oils-and-fats or waste thereof, with supercritical alcohol. According to the disclosed method, it is possible to produce high-purity fatty acid alkyl ester at low cost and high productivity.

Owner:EXST

Method for producing environment-friendly rubber filling oil from medium-low temperature coal tar

ActiveCN104593066ALow hydrogenation activityLow modification activityTreatment with hydrotreatment processesHydrogenation reactionFractionation

The invention discloses a method for producing producing environment-friendly rubber filling oil from medium-low temperature coal tar. The method comprises the following steps: medium-low temperature coal tar is subjected to fractionation, such that a light fraction and a heavy fraction are obtained; the light fraction is mixed with hydrogen, and the mixture enters a hydrogenation treatment reaction zone; the mixture sequentially contacts a hydrogenation protection catalyst, a hydro-refining catalyst and a hydro-upgrading catalyst A, such that a hydrogenation reaction is carried out; a hydrogenation treatment effluent is separated such that gas and water are separated; an obtained liquid-phase product enters a hydro-upgrading reaction zone; a hydro-upgrading catalyst B containing amorphous silica-alumina and modified Y zeolite and a hydro-finishing catalyst are adopted in the hydro-upgrading reaction zone, and a hydro-upgrading reaction is carried out under the existence of hydrogen; olefin produced during the hydro-upgrading process is saturated at the lower part of the hydro-upgrading reaction zone; and the obtained hydro-upgrading product is separated, such that the environment-friendly rubber filling oil is obtained. According to the invention, the medium-low temperature coal tar is adopted as a raw material, and can be used for producing the environment-friendly rubber filling oil with good low-temperature fluidity, good intersolubility with rubber, good oxidation stability, good safety and good environment friendliness.

Owner:CHINA PETROLEUM & CHEM CORP +1

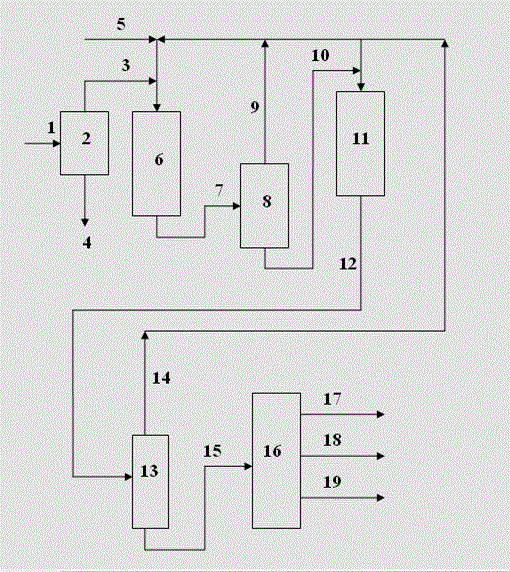

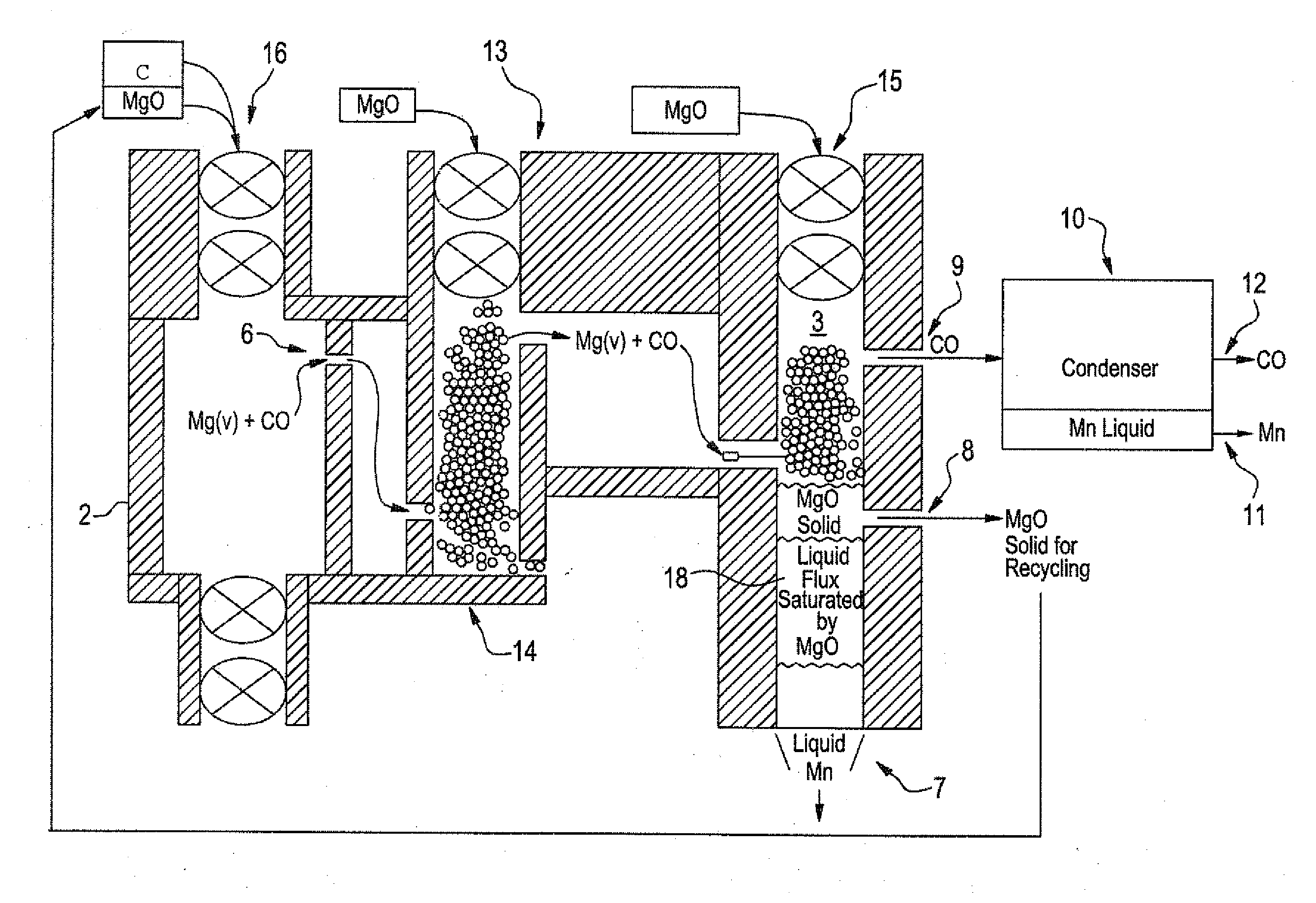

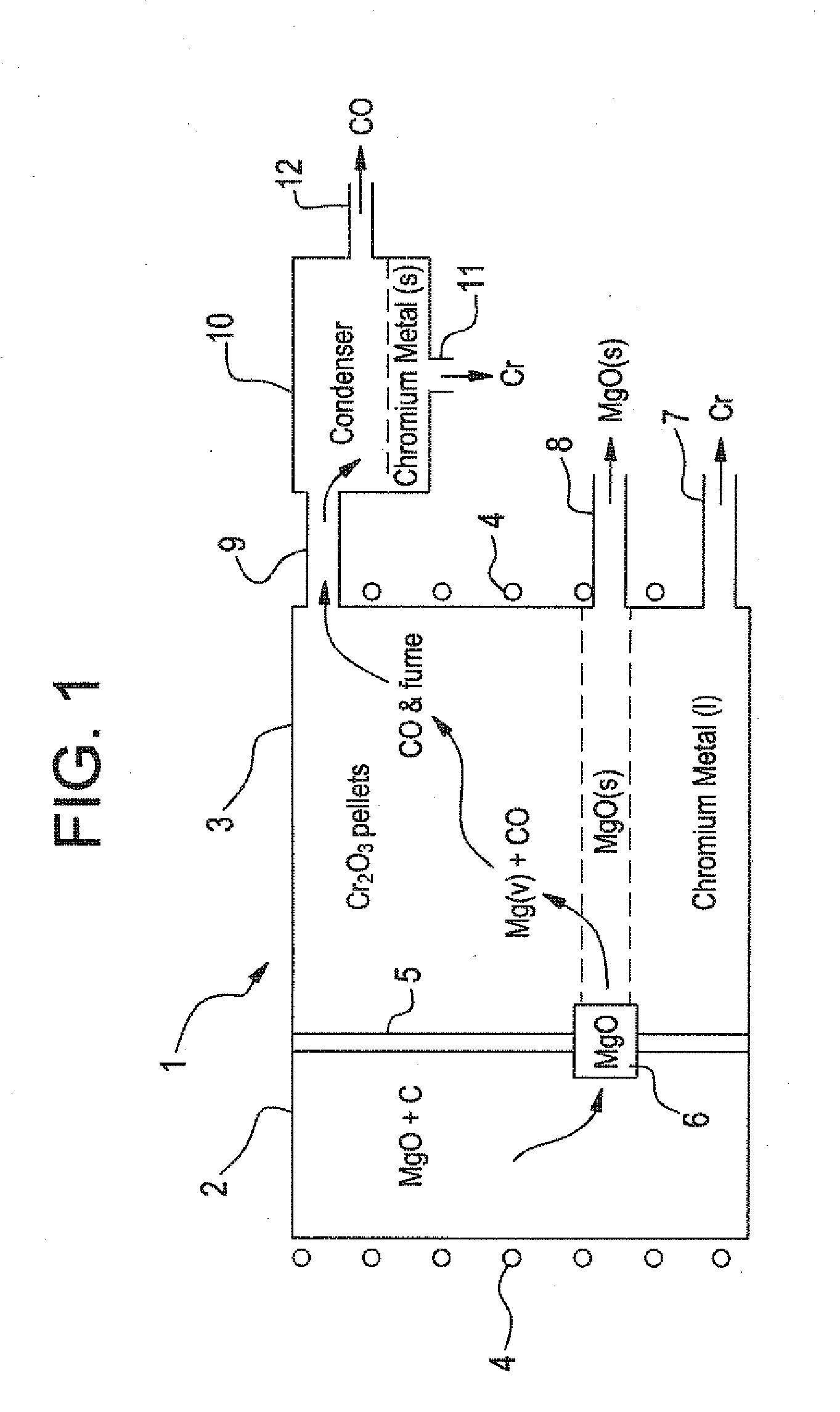

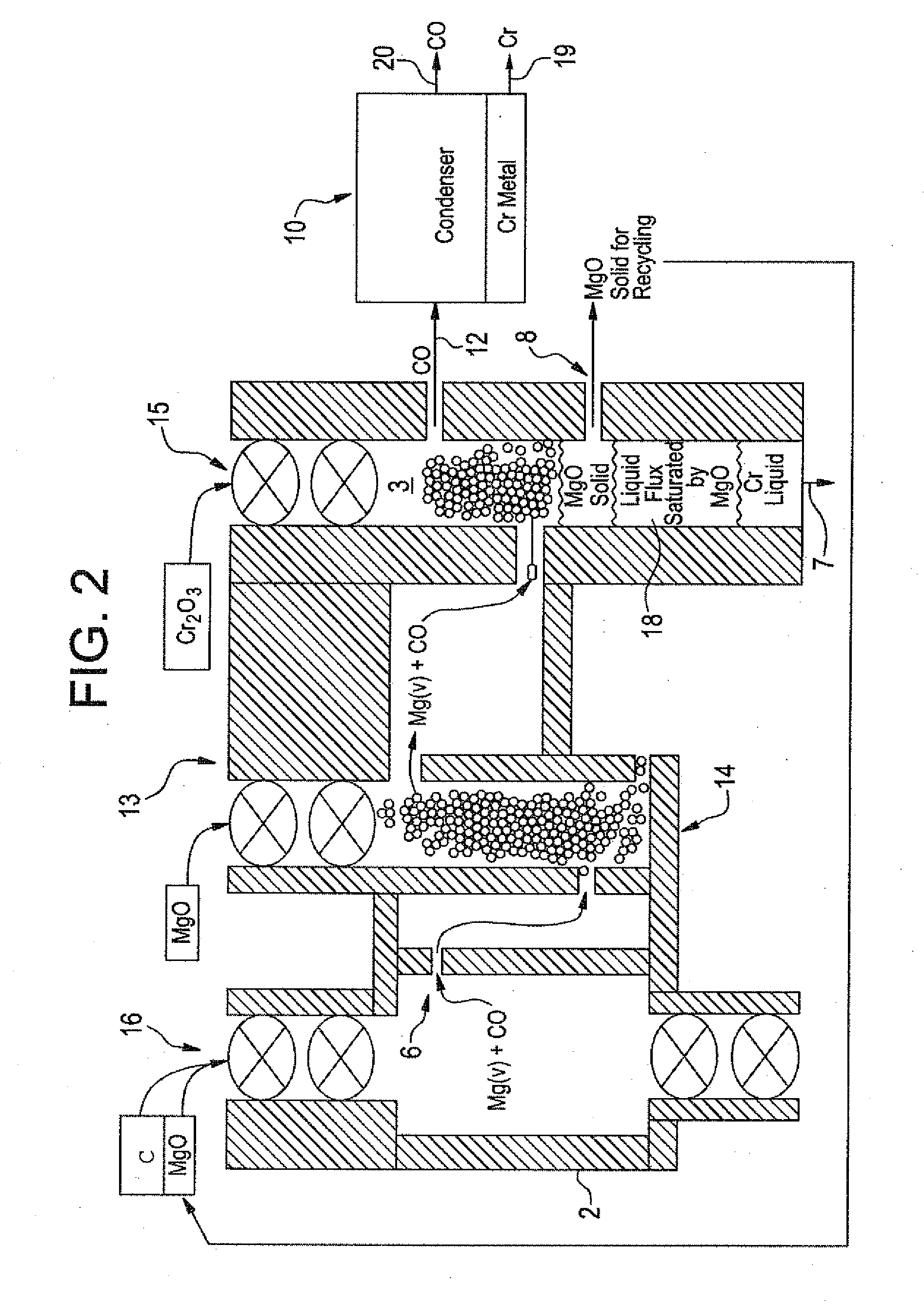

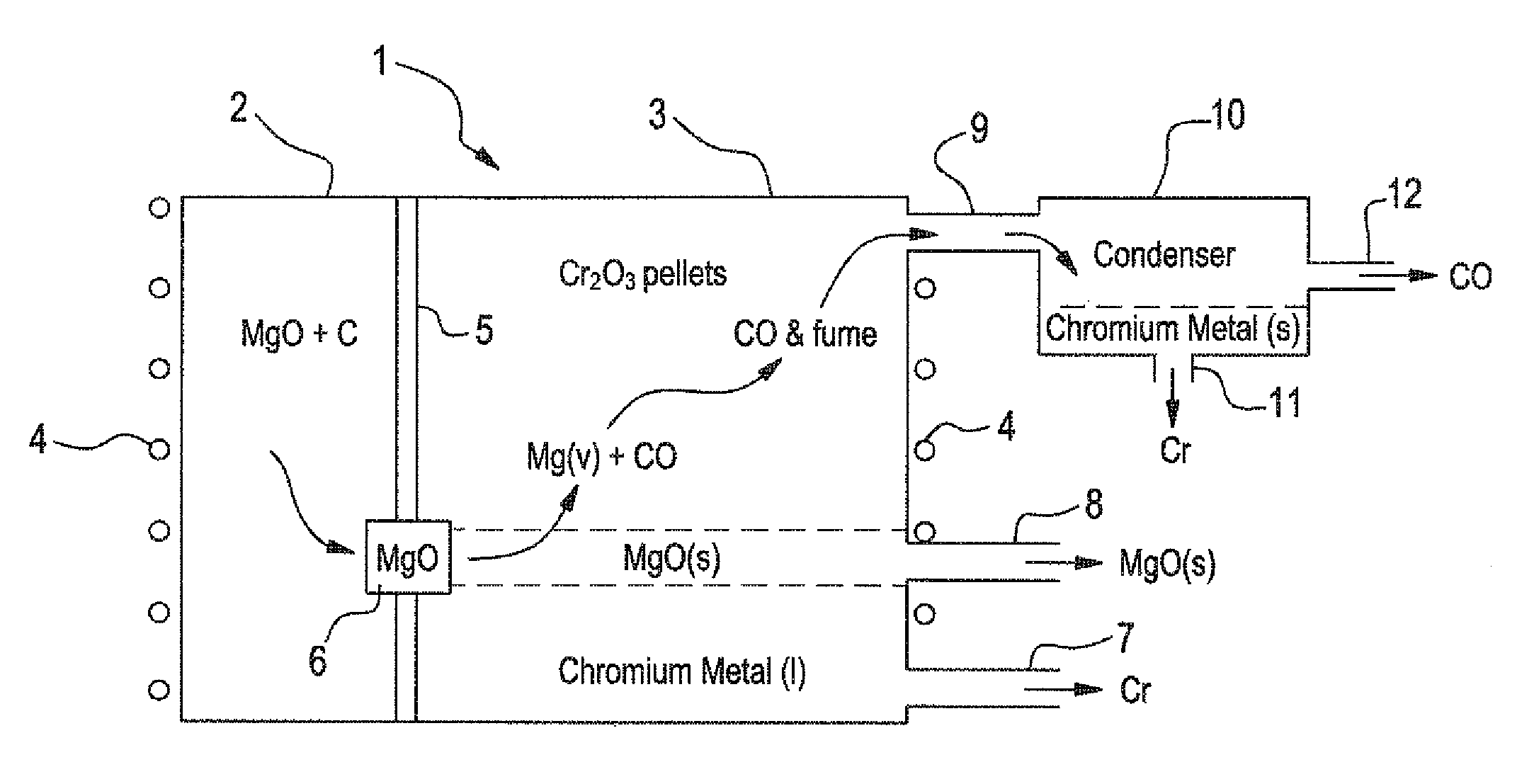

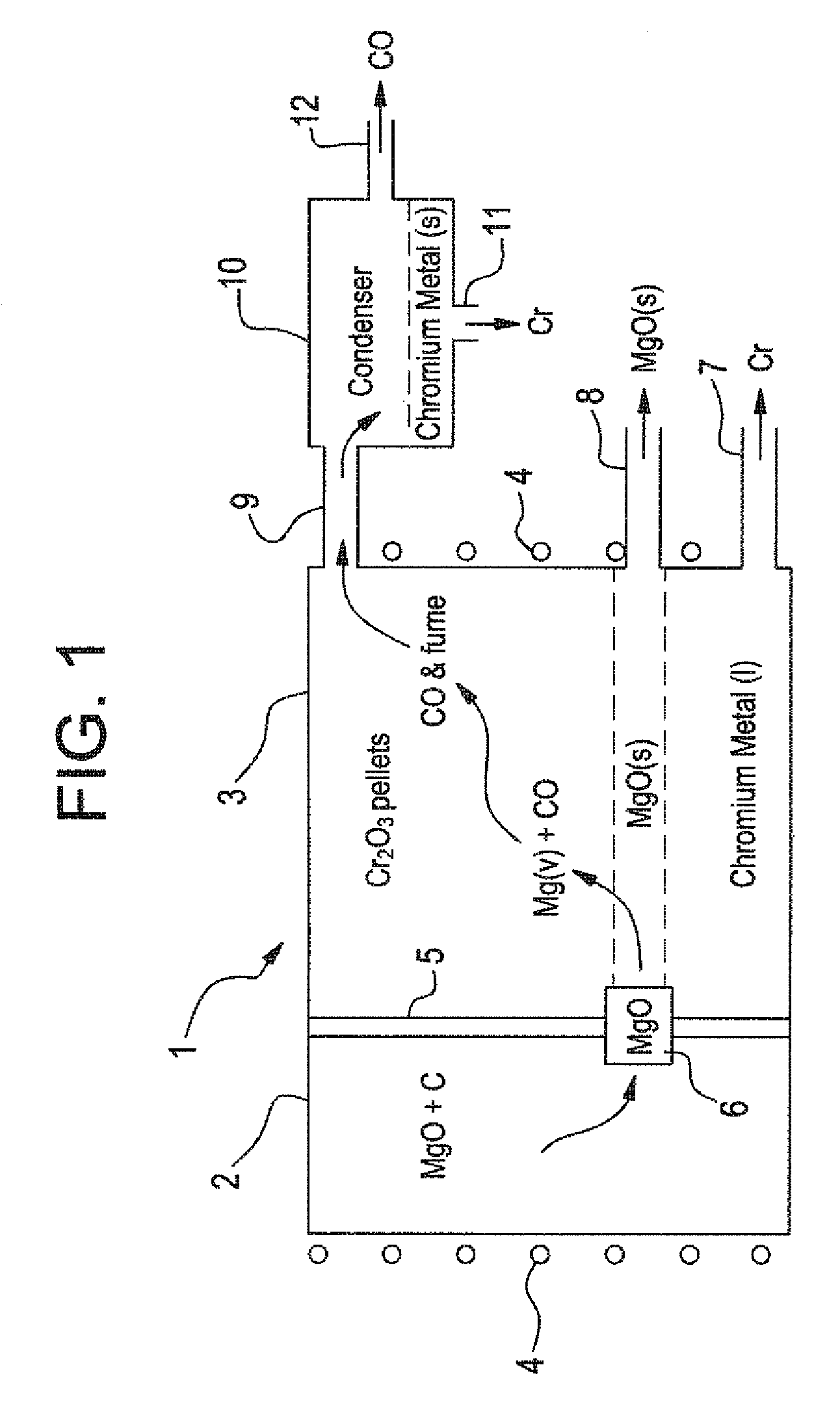

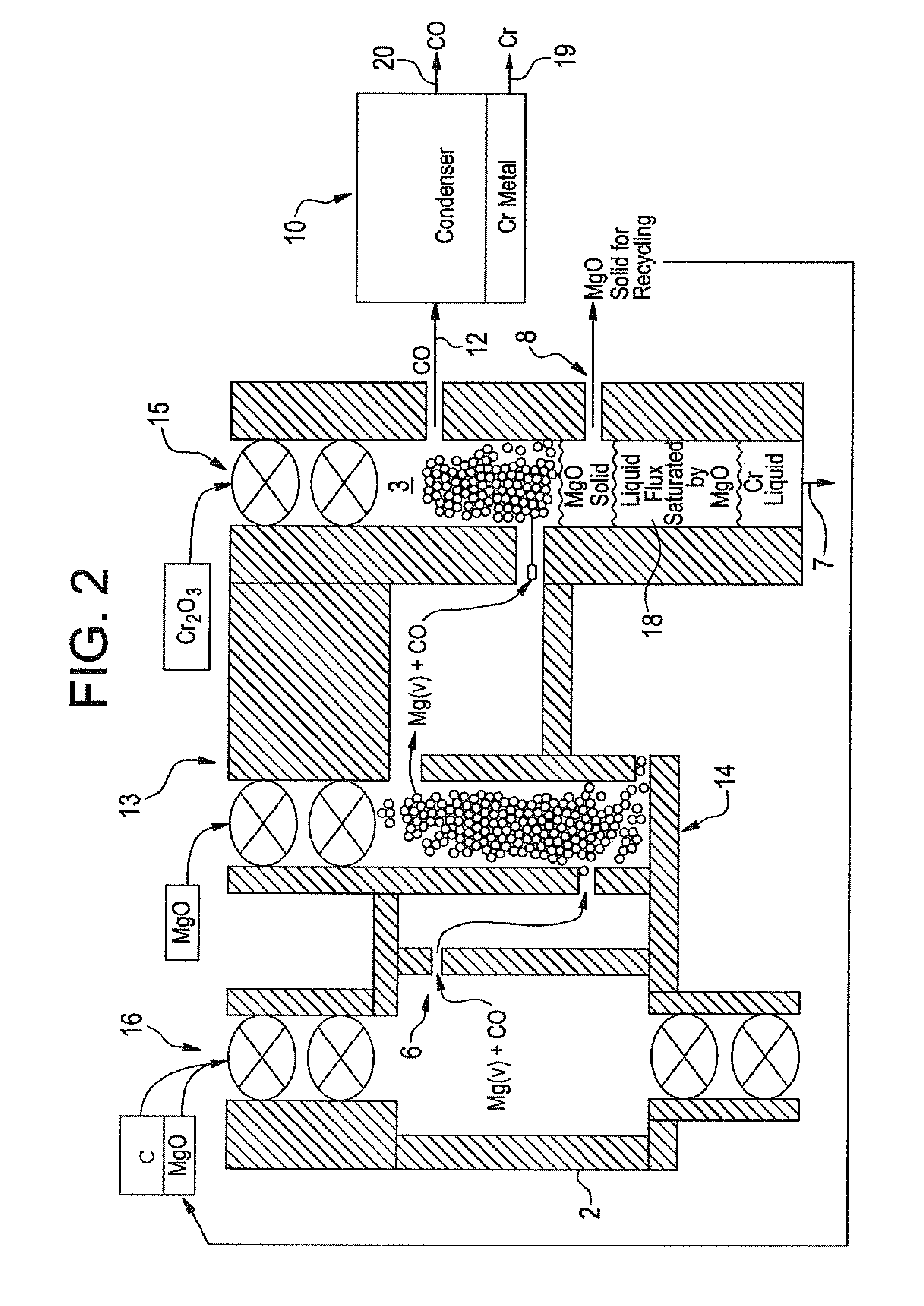

Method and apparatus for high temperature production of metals

Carbothermic reduction of magnesium oxide at approximately 2200 degrees Kelvin yields a high temperature mixture of magnesium vapors and carbon monoxide gas. Previous processes have sought to cool or alter the mixture to cause the yield of pure magnesium, which is then used in subsequent processes for its reducing properties. The present invention takes advantage of the stability and inertness of carbon monoxide at elevated temperatures enabling the magnesium vapor / carbon monoxide gas mixture from the carbothermic process to be used directly for the production of other metals at high temperatures. Chromium oxide, manganese oxide, zinc oxide and sulfide, and several other metal compounds can be reduced by the magnesium vapor / carbon monoxide gas mixture at temperatures high enough to prevent the gas mixture from back-reacting to magnesium oxide and carbon.

Owner:BARSA JOHN JOSEPH

Method for producing aviation kerosene by catalytic recycle oil hydrogenation

ActiveCN105733670ALow hydrogenation activityIncrease temperatureTreatment with hydrotreatment processesHigh densityKerosene

The present invention discloses a method for producing aviation kerosene by catalytic recycle oil hydrogenation. The method includes the following steps: mixing catalytic recycle oil with hydrogen, sending the mixture into a hydrogenation reaction zone; conducting hydrogenation in turn with a hydrogenation protective catalyst, a hydrofining catalyst and a hydro-upgrading catalyst A by contact; sending the hydrotreating effluent into a hydro-upgrading reaction zone using a hydro-upgrading catalyst B containing amorphous silica-alumina and modified Y zeolite, and carrying out a hydrogenation reforming reaction in the presence of hydrogen; sending the hydro-upgrading effluents into a hydrofinishing reaction zone, carrying out a hydrofinishing reaction and isolating hydrofinishing products to obtain the aviation kerosene with large proportion. The method uses catalytic recycle oil as raw material to produce the aviation kerosene with large proportion, high density, high volume calorific value, low aromatic content and good low temperature performance in the maximum amount, and can broaden the sources of raw materials for aviation kerosene products with large proportion.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation process of liquid sugar

InactiveCN106480234AReduce wasteAvoid the reverse reactionSugar productsSucrose extraction by chemical meansAcid hydrolysisCitric acid

The invention discloses a preparation process of liquid sugar. The preparation process comprises the following steps of (1) raw material preparation and treatment; (2) temperature rise concentration; (3) acid addition; (4) heat insulation conversion; (5) alkali addition for conversion stopping; (6) temperature reduction. Compared with the prior art, the preparation process of liquid sugar aims at an integral utilization technology of sugar production byproducts, uses a method of a weak acid hydrolysis method, and has the advantages that the reaction is mild; the content of reducing sugar can be conveniently controlled; the operation is simple and convenient; in addition, the generated syrup cannot easily precipitate; the state is stable; citric acid belongs to food grade additives, and the remained additives cannot be harm to the body.

Owner:南京甘汁园股份有限公司

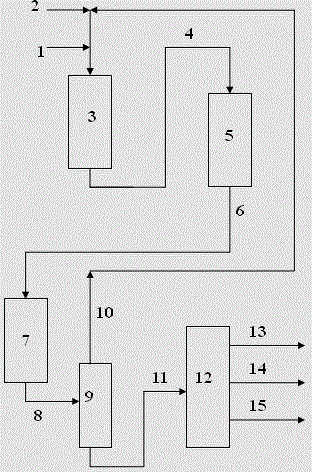

Environment friendly process for biodiesel

InactiveCN101486923AReduce consumptionReduce investmentBiofuelsLiquid hydrocarbon mixture productionLiquid wasteWax

The invention discloses environmental protection technology for bio-diesel production, which comprises the following units: 1) raw material preparation; 2) pre-esterification; 3) fine esterification; 4) washing desulphurization esterification; 5) refined methyl ester separation; 6) low-temperature dewaxing; 7) emission recovery; and 8) wastewater treatment. The environmental protection technology has the advantages that: 1. energy saving and emission reduction: the low temperature is served as technology heat and reduces the consumption of the energy; after the unit separation and purification, the produced exhaust gas and waste liquid can be reused in the technology, thus reducing the pollution emissions; 2. rapid esterification speed: high esterification rate; the hydrous grease is separated promptly by a liquid separating tank, thus avoiding a reverse reaction and reducing the esterification time to 1 hour; the acid value recovery problem is solved, so that the esterification is more thorough; the esterification rate can reach more than 98%; 3.output improving: the environmental protection technology has compact technology and reasonable procedure and can realize continuous and large-scale flowing production; and 4. low bio-diesel solidifying point: the wax in the bio-diesel is removed effectively by using a jacketed crystallizer and a full-automatic pressing filter, and the solidifying point is reduced.

Owner:迟洪军

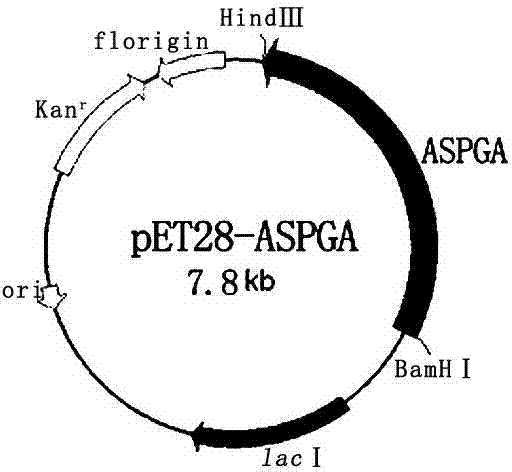

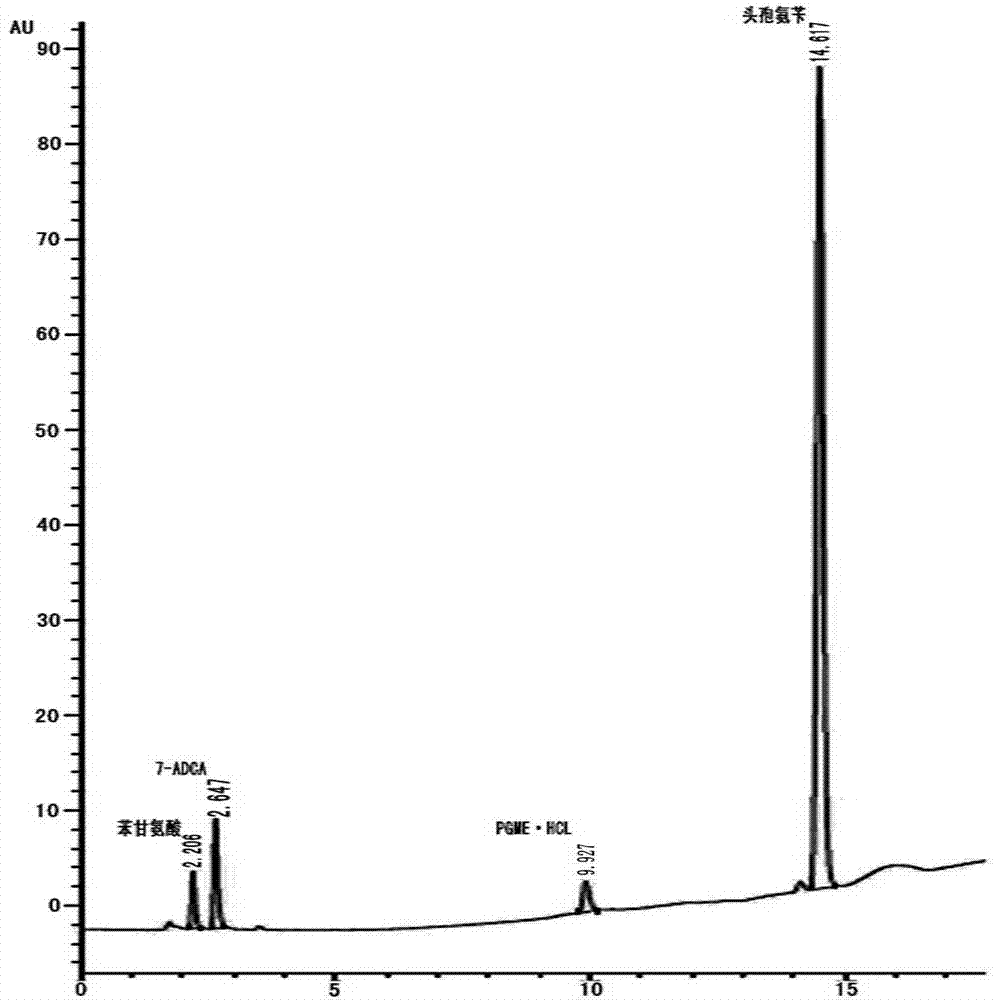

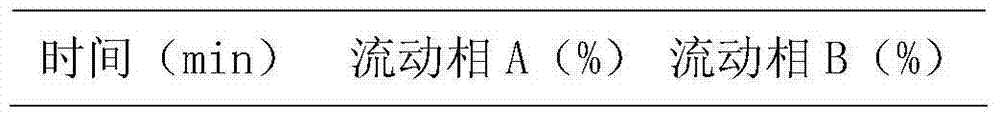

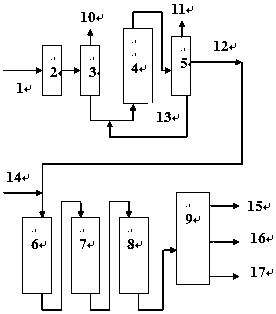

A kind of method for preparing cephalexin

The invention discloses a method for preparing cefalexin. The method comprises the steps of charging a D-2-phenylglycine ester derivative and 7-ADCA (amino desacetoxy cephalosporanic acid) in a molar ratio of (1.15-1.6):1, and adding a catalyst penicillin acylase with amount of 1-2 times of amount of the 7-ADCA for acylation reaction, wherein the coded gene sequence of the penicillin acylase is shown as SEQIDNO:3. The method effectively overcomes reverse reaction during enzyme condensation reaction, so as to greatly reduce the using amount of side chains, avoid the phenomenon that more impurities are generated when high side chains are consumed, and solve the problem that the objective product is difficult to purify; and besides, the 7-ADCA conversion rate can be greatly improved to be up to more than 98%, the product quality is further improved and the production cost is reduced.

Owner:NORTH CHINA PHARMA COMPANY

Hydrogenation regeneration method of waste lubricating oil

ActiveCN105733793BHigh yield utilizationIncreased operating lifeTreatment with hydrotreatment processesLubricant compositionHydrogenReaction zone

Owner:CHINA PETROLEUM & CHEM CORP +1

Device for producing hydrogen through decomposing water

ActiveCN101608316BIncrease profitImprove hydrogen production efficiencyCellsEnergy inputElectricityPhotoelectrochemical cell

The invention relates to a device for producing hydrogen through decomposing water, which comprises a photoelectrochemical cell including an optical anode and an optical cathode, and a solar cell which is used for generating voltage bias and includes an anode and a cathode, wherein the solar cell is electrically connected with the photoelectrochemical cell; the optical anode of the photoelectrochemical cell and the solar cell are arranged in the incident plane of sunshine. The device of producing hydrogen through decomposing water can overcome the problems of lower efficiency and hard hydrogen-oxygen separation during preparing hydrogen through semiconductor photocatalysis, solve the cost problem of photoelectrochemical hydrogen production, and simultaneously improve the operating factorsof sunshine.

Owner:ENN SCI & TECH DEV

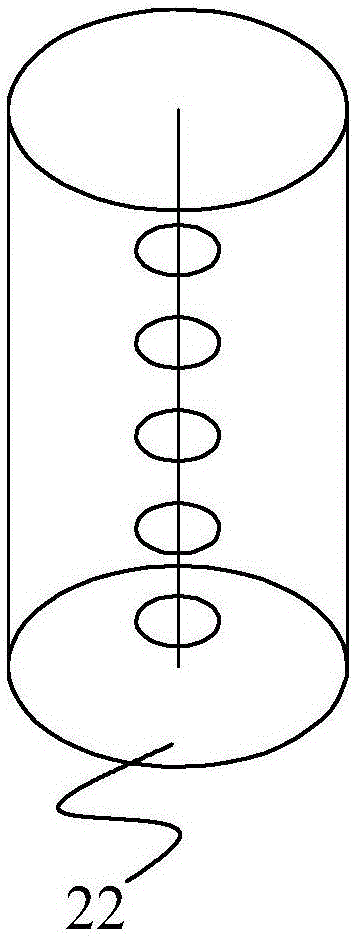

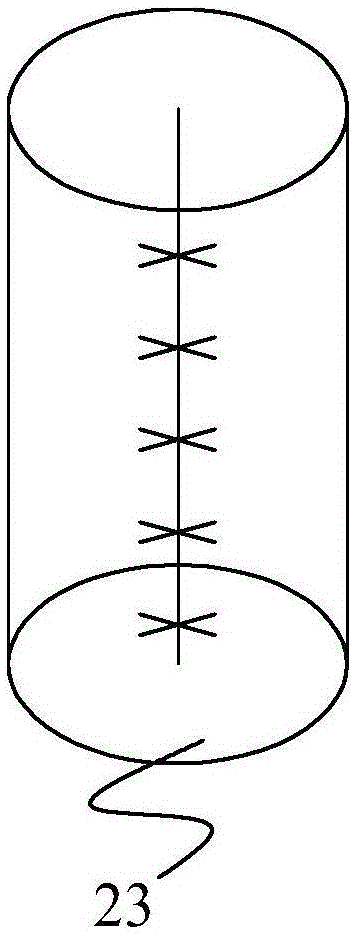

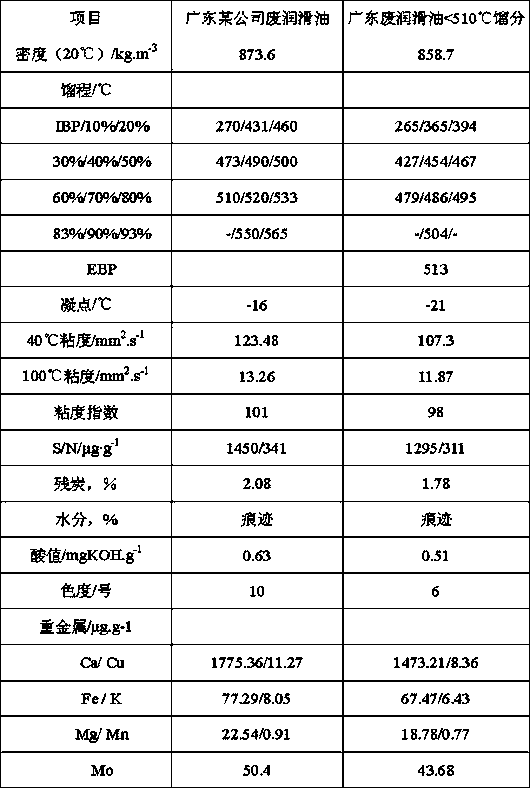

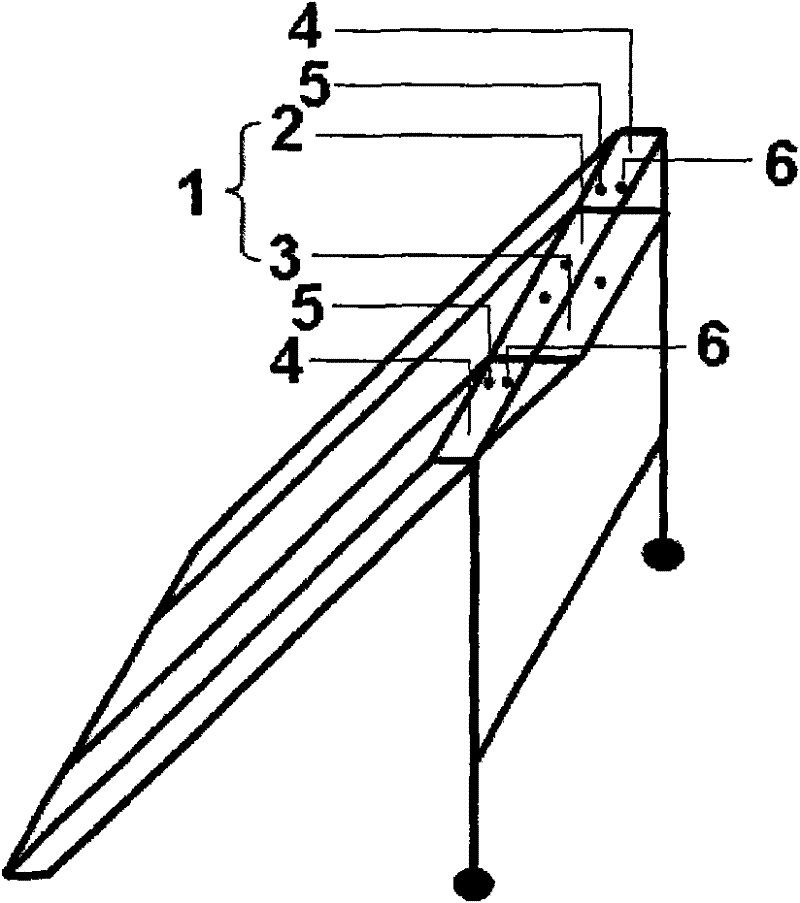

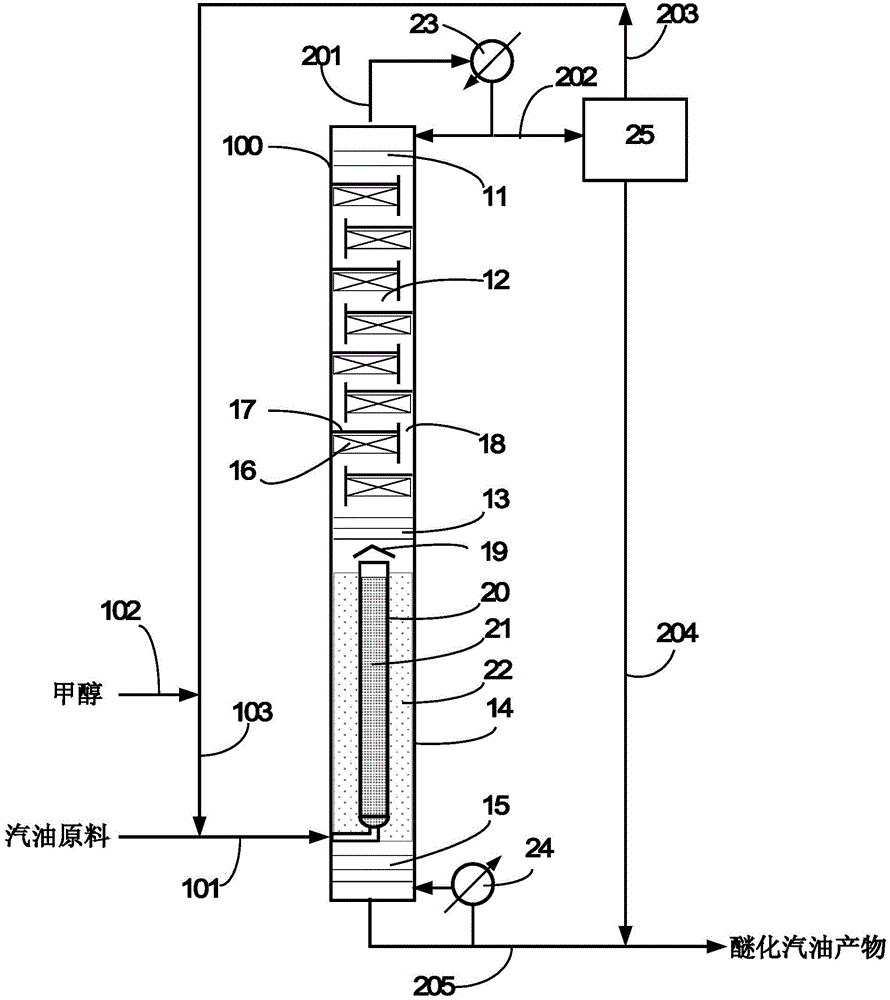

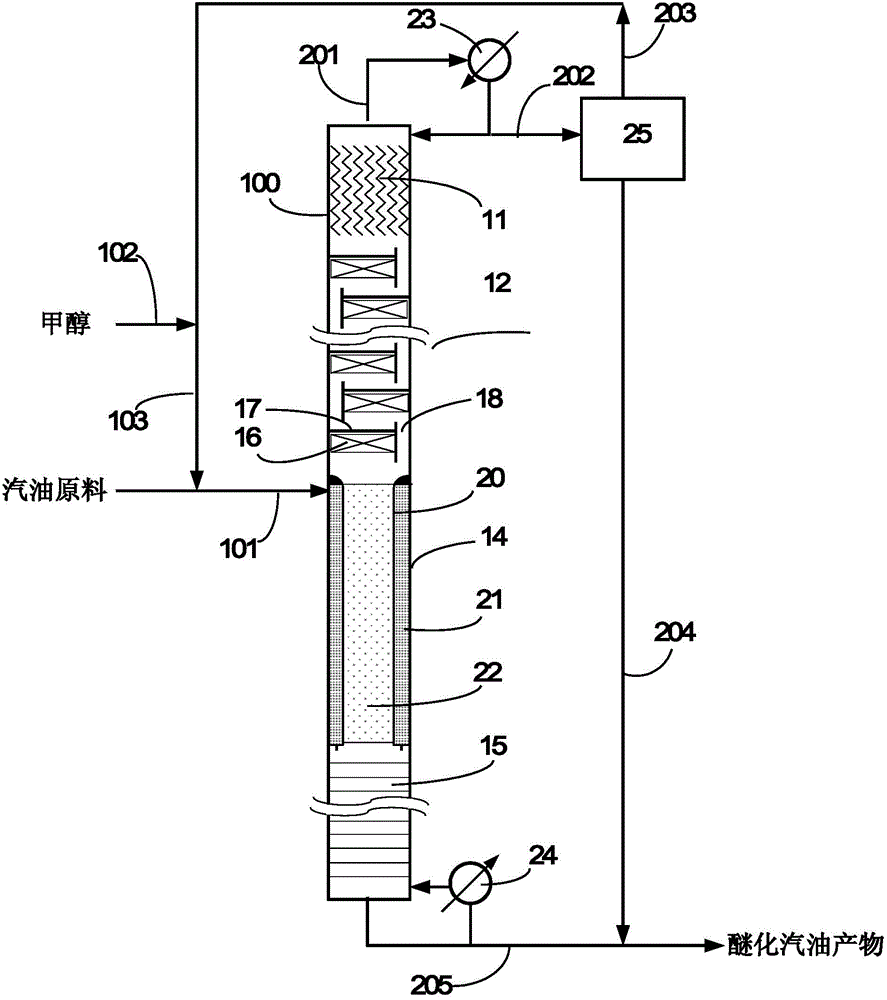

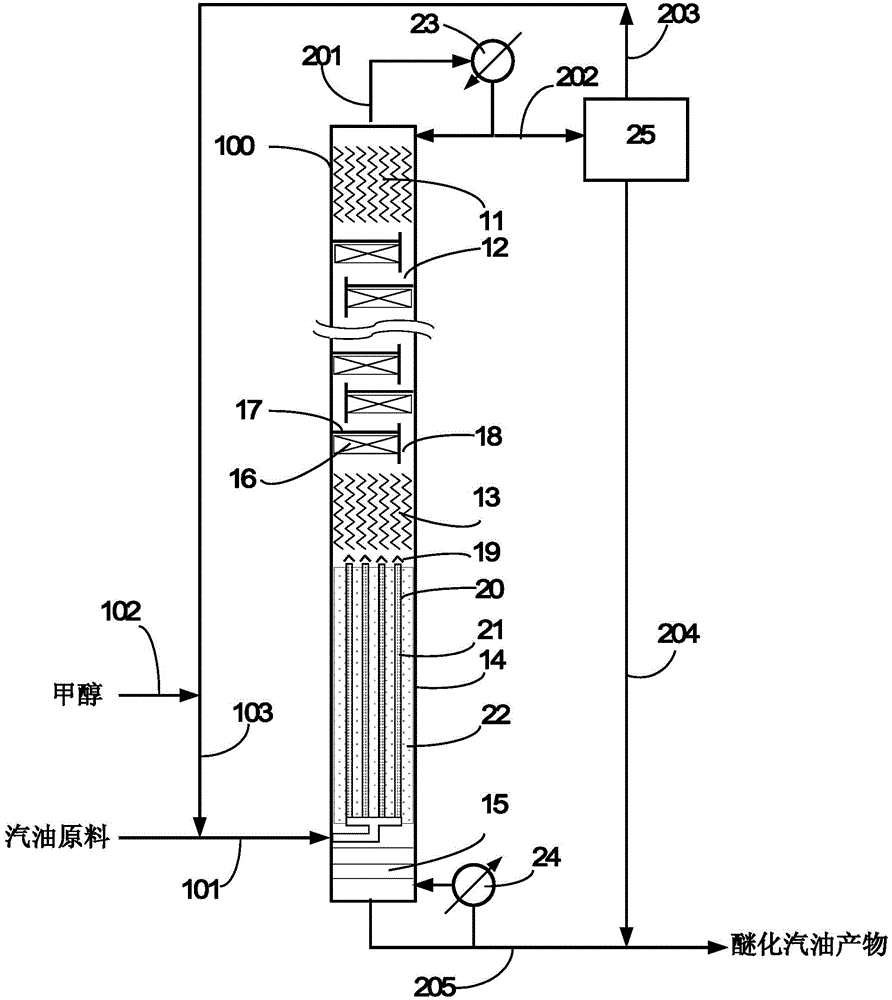

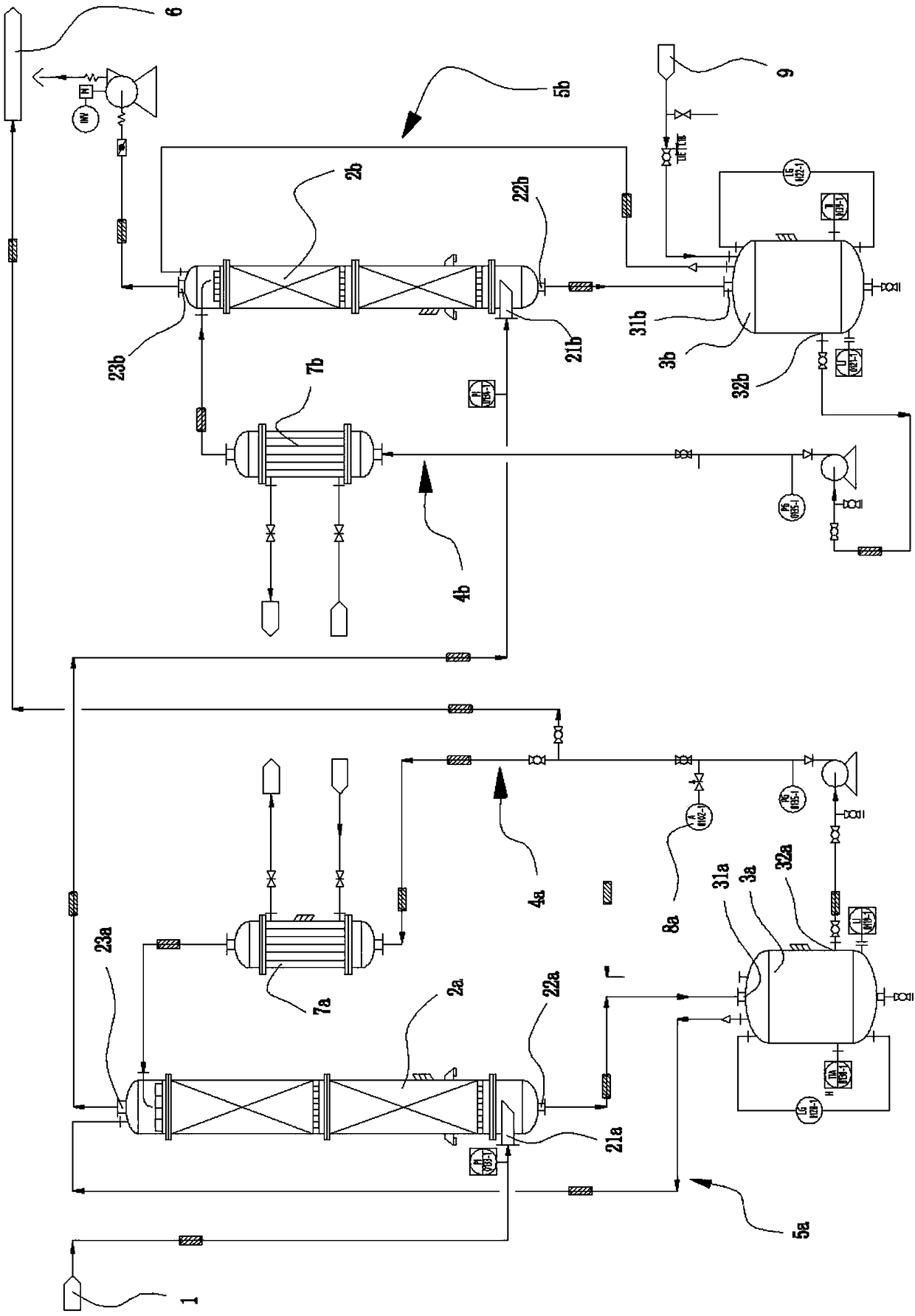

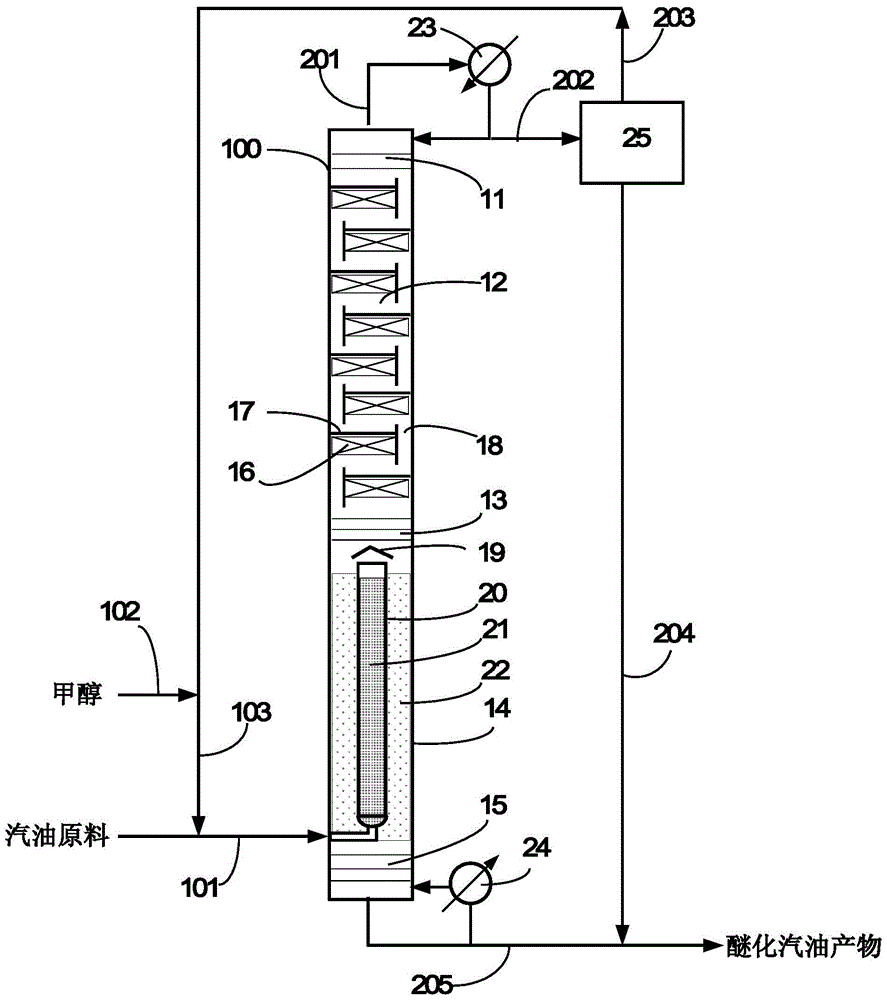

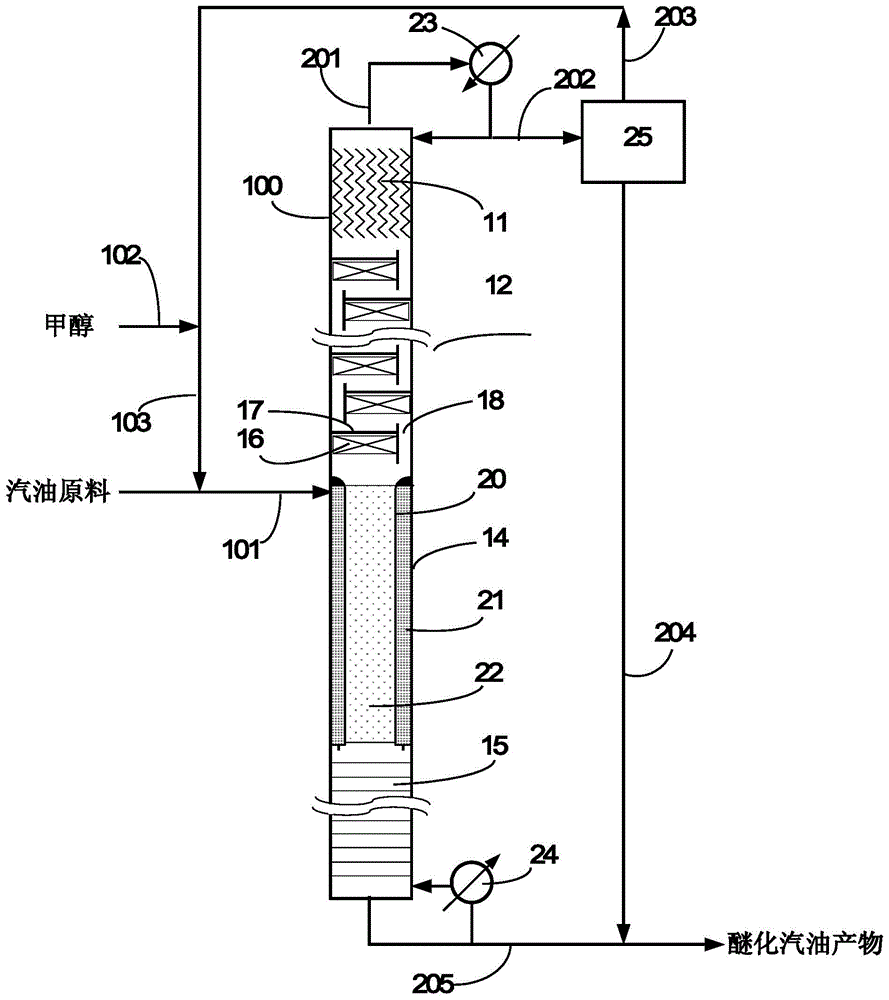

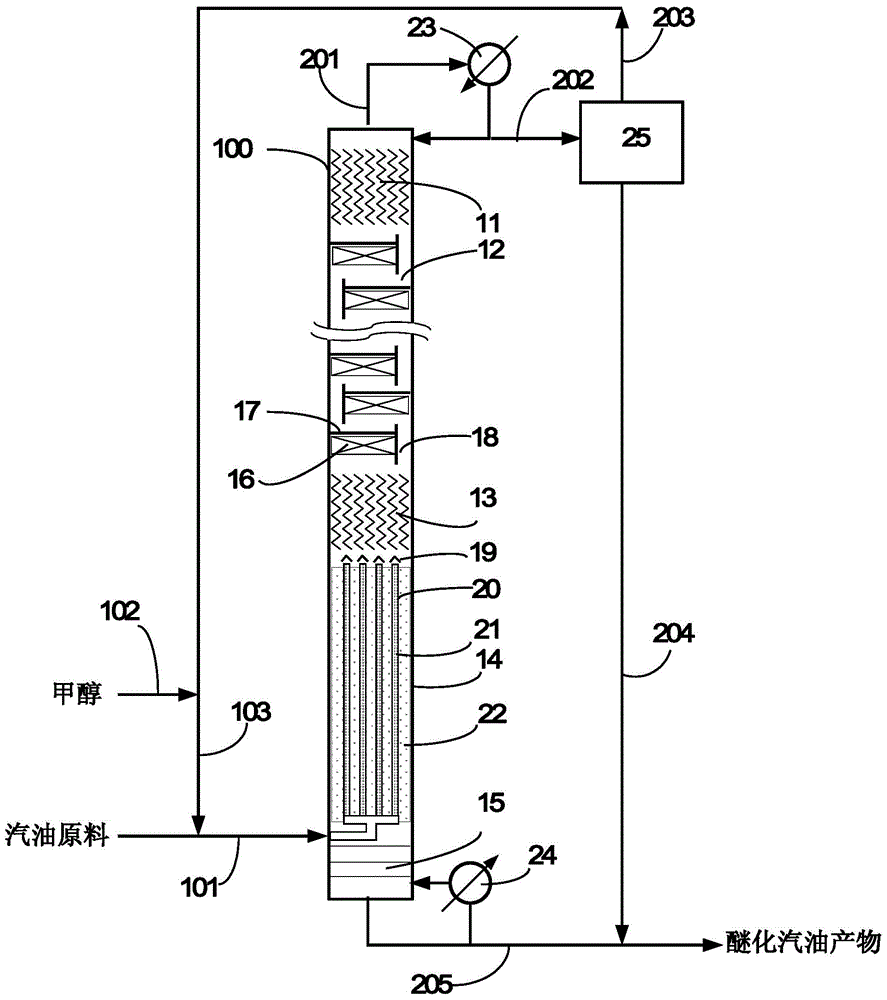

Etherification, catalysis and rectification method and device for increasing gasoline octane number

ActiveCN104694150AIncrease temperatureAvoid overall overheatingHydrocarbon distillationEtherFractionation

The invention relates to an etherification, catalysis and rectification method and device for increasing the gasoline octane number. The device comprises a catalysis and rectification tower of a nested and coupled structure, and the tower sequentially comprises a rectification section, a multi-stage unit catalysis and fractionation section, a middle fractionation section, a tube shell structure catalysis and fractionation section and a stripping section from top to bottom. By means of the structure of the tube shell structure catalysis and fractionation section, thermal coupling can be carried out on tube pass reaction heat dissipation and jacket fractionation heat absorbing, so that increasing of temperature of a catalyst bed layer is effectively prevented, the catalyst bed layer is prevented from being overheated, and energy consumption is reduced to the largest extent. By means of the structure of the multi-stage unit catalysis and fractionation section, a catalyst component is fixedly connected to the lower side of a tower plate and covers all gas channels of the tower plate, the product of ether flows down through a downcomer stage by stage and does not make contact with catalysts, stay time of the product of ether in the catalysts can be better shortened, secondary contact of the product of ether and the catalysts is avoided, and the problem that in the prior art, the reaction product of ether makes contact with the catalysts repeatedly when flowing down along with liquid and accordingly a reverse reaction is caused is solved.

Owner:TIANJIN UNIV

Tail-gas recovery system in production of diketene

ActiveCN108854460AEmission reductionIncrease profitGas treatmentDispersed particle separationProcess engineeringExhaust gas

The invention discloses a tail-gas recovery system in production of diketene. The tail-gas recovery system comprises a tail-gas source, tail-gas absorbing equipment and tail-gas absorbing product receiving equipment, wherein the tail-gas source is used for collecting tail gas produced by a diketene production system and guiding the flowing direction of the tail gas; the tail-gas absorbing equipment provides a place of tail-gas absorption for an absorbing medium and is communicated with the tail-gas source; the tail-gas absorbing product receiving equipment is connected with the tail-gas absorbing equipment and is mainly used for receiving and / or storing tail-gas absorbing products generated in the tail-gas absorbing equipment. The tail-gas recovery system in production of diketene disclosed by the invention has the beneficial effects that recovery for effective components in the tail gas can be realized by high efficiency, and the economic values of the recovered products can be continuously exerted.

Owner:QINGDAO DOUBLE PEACH SPECIALTY CHEM GRP +1

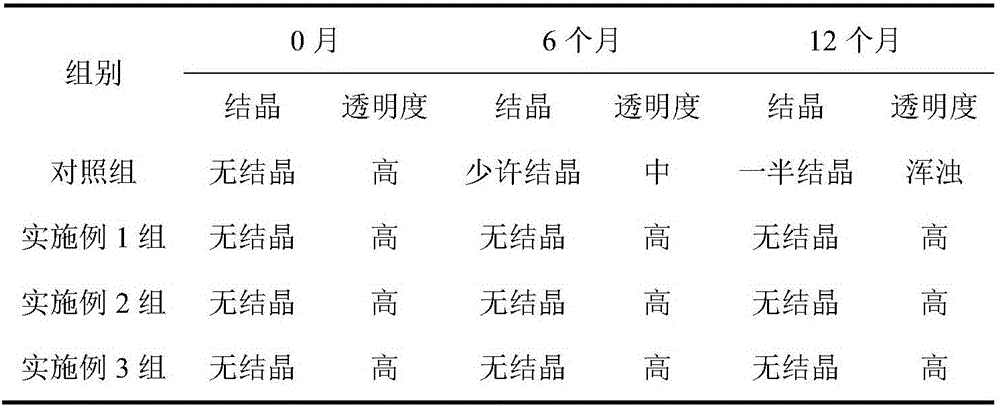

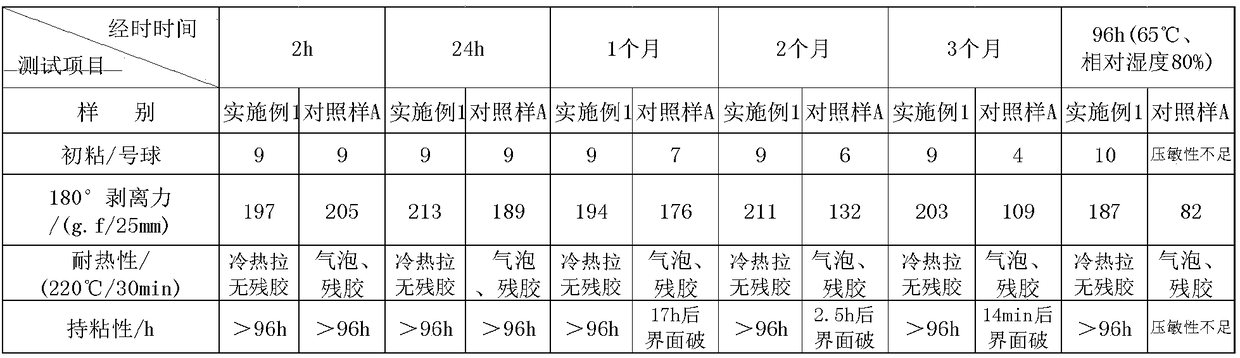

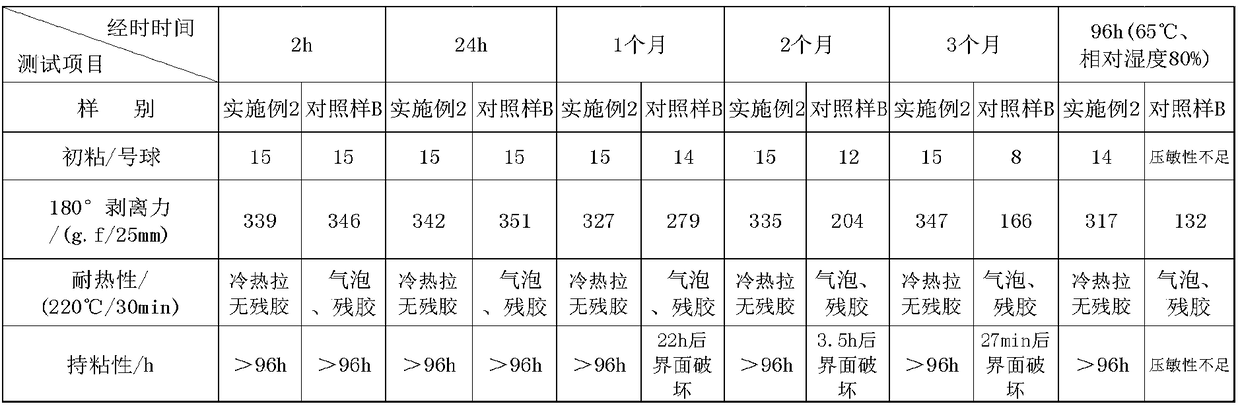

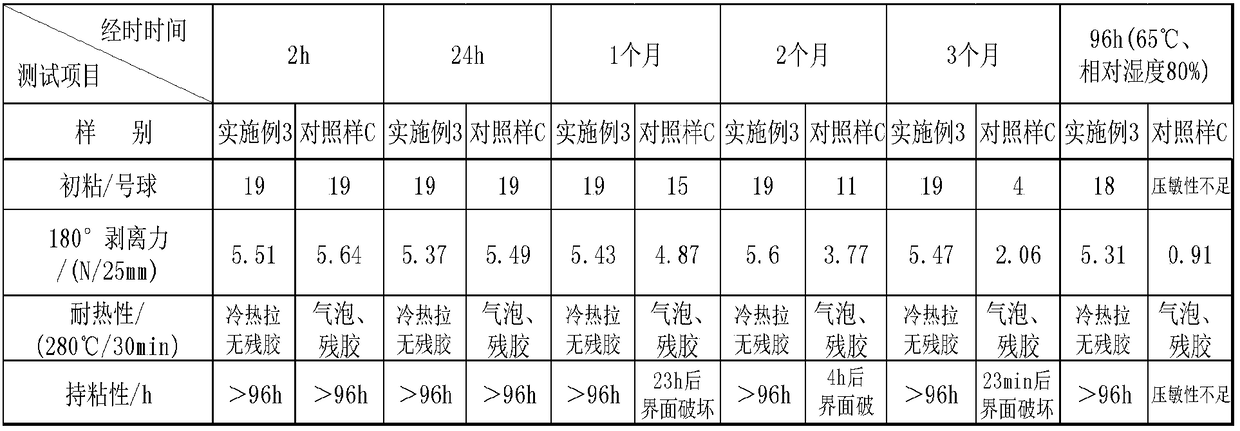

A method for improving the stability of silicone pressure-sensitive adhesives for protective films

ActiveCN105441017BStable temperature resistanceImprove storage performanceAdhesivesCarboxylic acidKetone

The invention relates to a method for improving stability of an organosilicone pressure-sensitive adhesive for a protective film. The method comprises steps as follows: step 1), removal of water and hydroxyl: a water and hydroxyl removal agent containing organic acyloxy silane compounds is added to a reaction system to reduce water left in the adhesive and hydroxyl left on an adhesive structure; step 2), thorough inactivation of a catalyst: a) when primary amine or secondary amine is used as a condensation polymerization catalyst, an adhesive reaction system is kept at the temperature of about 70 DEG C at the nitrogen reaction atmosphere, primary amine or secondary amine and aldehydes, ketones or low-level carboxylic acid react to generate Schiff base, generated unstable Schiff base reacts with diethyl malonate, and Schiff base becomes beta-amino acid without catalytic activity; b), when secondary amine or tertiary amine is used as a condensation polymerization catalyst, acidic compounds which can react with secondary amine or tertiary amine to generate a stable compound are added to the reaction system; step 3), residual small molecular substances are removed in the vacuum state; step 4), neutralization of residual acidic compounds: sodium alcoholate is added to neutralize residual acidic compounds in the adhesive.

Owner:ANHUI MINGXUN NEW MATERIAL TECH

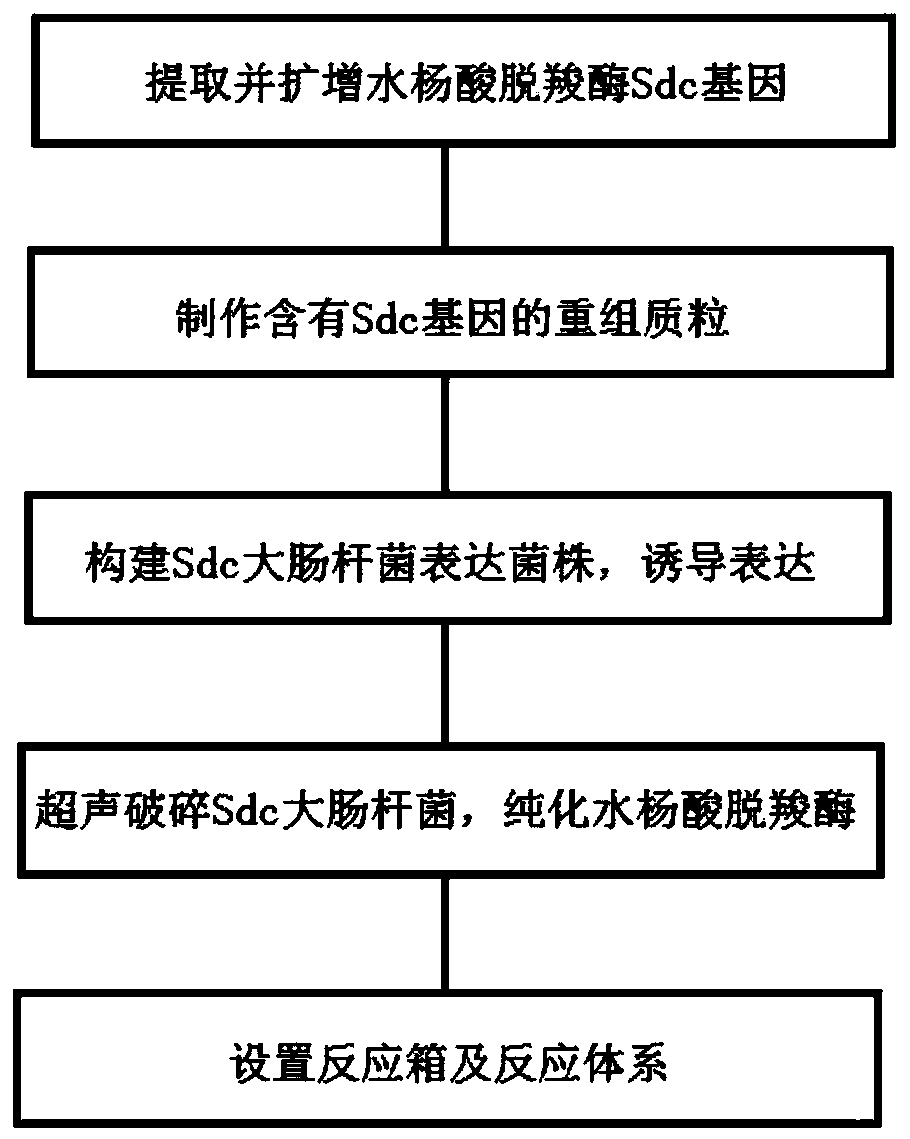

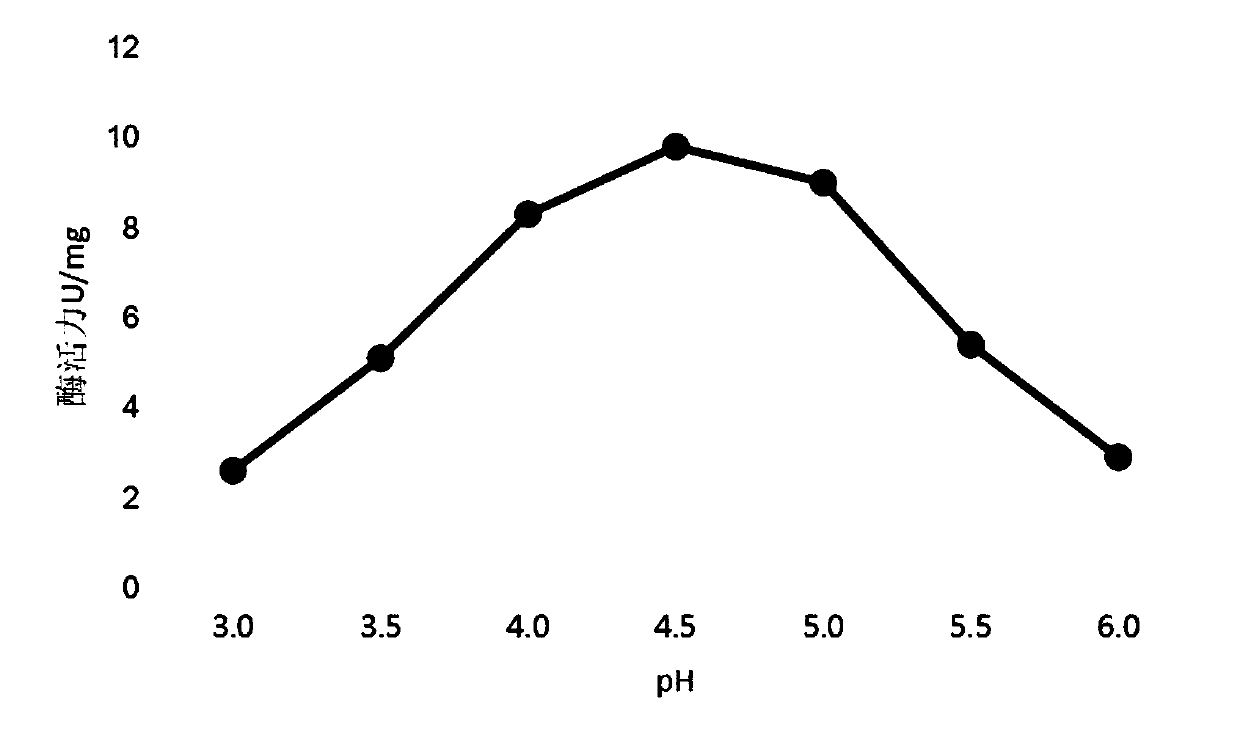

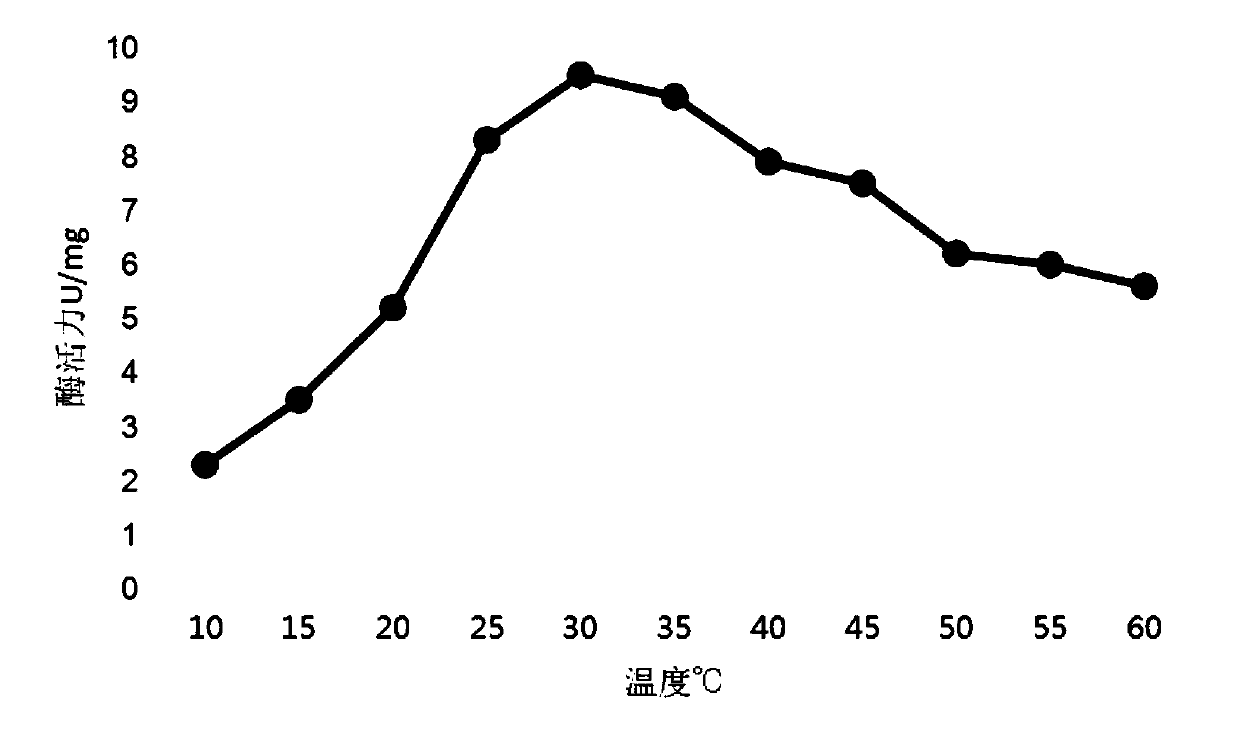

Method of enzymatic degradation of 4-aminosalicylic acid

InactiveCN110205316AHigh reactivityAccurate measurementMicrobiological testing/measurementFermentationEscherichia coliPara-aminosalicylic acid

The invention discloses a method of enzymatic degradation of 4-aminosalicylic acid. The method includes: extracting and amplifying salicylic acid decarboxylase Sdc genes; preparing recombinant plasmids containing the Sdc genes; constructing Escherichia coli Sdc expression strains for inducible expression; performing ultrasonic fragmentation of Escherichia coli Sdc and purification of salicylic acid decarboxylase; arranging a reaction box and a reaction system. In the method, technical conditions that high temperature is needed for degradation of 4-aminosalicylic acid are replaced, so that thedecomposition reaction is easier to carry out, and the degradation efficiency is higher; a large number of salicylic acid decarboxylase can be prepared by genetic engineering, so that the applicationof the salicylic acid decarboxylase can be industrialized, and the metabolic yield per unit time can be increased; the reaction system with the highest metabolic efficiency is prepared, ferrous chloride is added in the reaction system, a pumping pump is arranged on the reaction box, the enzyme reaction activity can be improved, the occurrence of reverse reaction is prevented, and the decompositionefficiency is improved; mass spectrometry is more accurate than colorimetric method in the prior art in measuring the enzyme activity.

Owner:JINING UNIV

Process for preparing lubricating oil base oil through hydrogenation regeneration of waste lubricating oil

PendingCN114085683ASolve the problem of not being able to run continuously for a long period of timeSolve the problem of poor light stabilityTreatment with hydrotreatment processesLubricant compositionPolycyclic aromatic hydrocarbonDistillation

The invention relates to a process for preparing lubricating oil base oil through hydrogenation regeneration of waste lubricating oil. The process comprises the following steps: mechanical filtration, boiling bed refined water removal and Cl removal, hydrofining, polycyclic aromatic hydrocarbon removal, hydrogenation pour point depression and distillation separation. Raw materials are subjected to mechanical filtration and coarse impurity removal, then enter a fluidized bed reactor to be subjected to fine dehydration and Cl removal, olefin, S, N and other impurities in lubricating oil are removed through a hydrofining reactor, fractionation is carried out to obtain lubricating oil base oil, and the refined lubricating oil base oil passes through a polycyclic aromatic hydrocarbon removal device and finally enters a hydrogenation pour point depressing reactor to be subjected to hydrogenation pour point depressing treatment, so that the added value of the product is further improved. The production process can be continuously operated for a long period, is environment-friendly and pollution-free, has a waste oil regeneration recovery rate of more than 95%, and can obviously improve the added value of products and increase economic benefits.

Owner:湖北科润石化科技有限公司

Method and apparatus for high temperature production of metals

Carbothermic reduction of magnesium oxide at approximately 2200 degrees Kelvin yields a high temperature mixture of magnesium vapors and carbon monoxide gas. Previous processes have sought to cool or alter the mixture to cause the yield of pure magnesium, which is then used in subsequent processes for its reducing properties. The present invention takes advantage of the stability and inertness of carbon monoxide at elevated temperatures enabling the magnesium vapor / carbon monoxide gas mixture from the carbothermic process to be used directly for the production of other metals at high temperatures. Chromium oxide, manganese oxide, zinc oxide and sulfide, and several other metal compounds can be reduced by the magnesium vapor / carbon monoxide gas mixture at temperatures high enough to prevent the gas mixture from back-reacting to magnesium oxide and carbon.

Owner:BARSA JOHN JOSEPH

Etherification catalytic rectification method and device for increasing gasoline octane number

ActiveCN104694150BIncrease temperatureAvoid overall overheatingHydrocarbon distillationFractionationEther

The invention relates to an etherification, catalysis and rectification method and device for increasing the gasoline octane number. The device comprises a catalysis and rectification tower of a nested and coupled structure, and the tower sequentially comprises a rectification section, a multi-stage unit catalysis and fractionation section, a middle fractionation section, a tube shell structure catalysis and fractionation section and a stripping section from top to bottom. By means of the structure of the tube shell structure catalysis and fractionation section, thermal coupling can be carried out on tube pass reaction heat dissipation and jacket fractionation heat absorbing, so that increasing of temperature of a catalyst bed layer is effectively prevented, the catalyst bed layer is prevented from being overheated, and energy consumption is reduced to the largest extent. By means of the structure of the multi-stage unit catalysis and fractionation section, a catalyst component is fixedly connected to the lower side of a tower plate and covers all gas channels of the tower plate, the product of ether flows down through a downcomer stage by stage and does not make contact with catalysts, stay time of the product of ether in the catalysts can be better shortened, secondary contact of the product of ether and the catalysts is avoided, and the problem that in the prior art, the reaction product of ether makes contact with the catalysts repeatedly when flowing down along with liquid and accordingly a reverse reaction is caused is solved.

Owner:TIANJIN UNIV

Device and method for cleaning pipelines for cationic polyester melts

InactiveCN103658121BPrevent dehydration and carbonizationReach applied technologyChemical industryPlastic recyclingPolyesterFour-way valve

The invention discloses a device and a method for cleaning pipelines for cationic polyester melts. The device comprises a melt discharge pump; the melt discharge pump is mounted on a polyester melt discharge pipeline of a cationic polyester melt manufacturing device; the polyester melt discharge pipeline is connected with a melt four-way valve; the melt discharge pump is connected with a first pipeline; the first pipeline is connected with an electric heater; the electric heater is connected with a public engineering steam system by a second pipeline; a steam valve is mounted on the first pipeline; a nitrogen pipeline is mounted on the first pipeline between the steam valve and the melt discharge pump; a third pipeline is mounted on the polyester melt discharge pipeline between the melt discharge pump and the melt four-way valve; the third pipeline is connected with a cleaning collecting vehicle by a metal hose; a melt blow-off valve is mounted on the third pipeline; the cleaning collecting vehicle is connected with a cleaning waste liquid receiving device by a fourth pipeline. The device and the method have the advantages that the pipelines for the cationic polyester melts can be cleaned by the aid of the device and the method, equipment can be prevented from being corroded, energy can be saved, and environments can be protected.

Owner:浙江东华纤维制造有限公司

Tail gas recovery system in the production of diketene

ActiveCN108854460BReduce qualityControl concentrationGas treatmentDispersed particle separationProcess engineeringEnvironmental engineering

The invention discloses a tail gas recovery system in the production of diketene, comprising: a tail gas source for collecting the tail gas produced by the diketene production system and guiding the flow direction of the tail gas; tail gas absorption equipment for providing a place for the absorption medium to absorb the tail gas , and communicate with the tail gas source; the tail gas absorption product receiving device is connected with the tail gas absorption device, and is mainly used to receive and / or store the tail gas absorption product generated in the tail gas absorption device. The tail gas recovery system in the production of diketene introduced by the invention can efficiently recover the active components in the tail gas, and the recovered products can continue to exert their economic value.

Owner:QINGDAO DOUBLE PEACH SPECIALTY CHEM GRP +1

A kind of catalytic hydrogenation process method for oil refining

ActiveCN104593059BLow hydrogenation activityIncrease temperatureTreatment with hydrotreatment processesHydrogenation reactionHydrogenation process

The invention discloses a hydrogenation process for FCC recycle oil. The method comprises the following steps that: after mixing of FCC recycle oil with hydrogen, the obtained mixture enters a hydro-treating reaction zone and sequentially contacts with a hydro-protecting catalyst, a hydrofining catalyst and a hydro-upgrading catalyst A for hydrogenation reaction; the effluent obtained after hydro-treatment enters a hydro-upgrading reaction zone where a hydro-upgrading catalyst B containing amorphous silicon aluminum and modified Y zeolite is used, and undergoes hydro-upgrading reaction in the presence of hydrogen; and the effluent obtained after hydro-upgrading enters a hydro-finishing reaction zone and undergoes hydro-finishing reaction, and hydro-finishing products are separated so as to obtain transformer oil. The hydrogenation processing method for FCC recycle oil provided by the invention uses FCC recycle oil as a raw material to produce transformer oil, so raw material sources of transformer oil products can be broadened and special oil products meeting higher quality requirements can be produced.

Owner:CHINA PETROLEUM & CHEM CORP +1

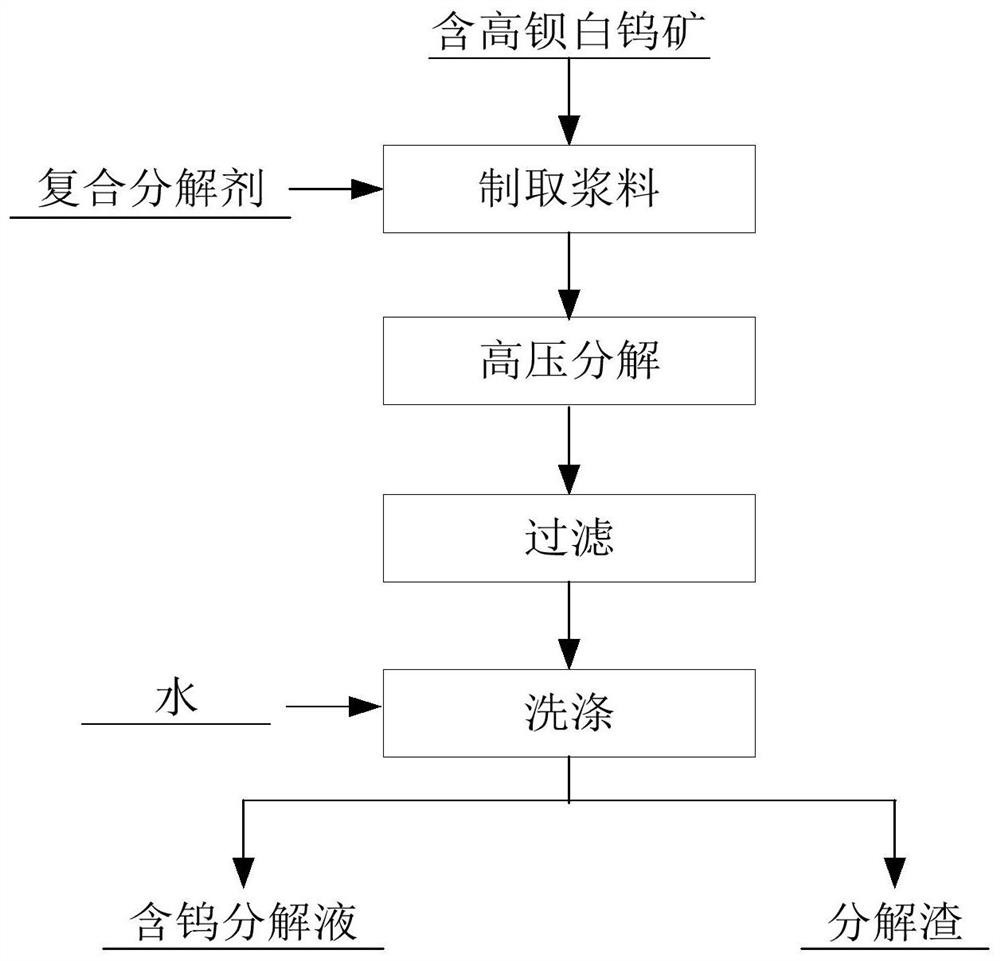

A kind of scheelite decomposing agent and method for extracting tungsten from scheelite

ActiveCN110042232BImprove decomposition rateImprove leaching rateProcess efficiency improvementPhysical chemistrySodium nitrate

The invention provides a scheelite decomposing agent. The scheelite decomposing agent comprises sodium nitrate, sodium hydroxide and sodium carbonate. The invention further provides a method for extracting the tungsten from the scheelite. The method comprises the following steps of S1, mixing the scheelite with the scheelite decomposing agent to prepare a thick liquid; S2, carrying out decomposition reaction on the scheelite and the scheelite decomposing agent to obtain a decomposed thick liquid; S3, filtering and separating the decomposed thick liquid to obtain a tungsten decomposition liquidand decomposition slag. According to the scheelite decomposing agent and the method, a mixture of sodium nitrate, sodium hydroxide and sodium carbonate is adopted as a decomposing agent, the decomposing agent and the scheelite are subjected to decomposition reaction, the three components cooperate with each other to achieve a synergistic effect, the high-barium scheelite can be well decomposed, the decomposition rate is high, the leaching rate of the tungsten is high, the energy consumption is low, and the cost is low.

Owner:JIANGXI UNIV OF SCI & TECH

A method for producing high specific gravity aviation kerosene by catalyzing oil refining hydrogenation

ActiveCN105733670BLow hydrogenation activityIncrease temperatureTreatment with hydrotreatment processesHigh densityKerosene

The present invention discloses a method for producing aviation kerosene by catalytic recycle oil hydrogenation. The method includes the following steps: mixing catalytic recycle oil with hydrogen, sending the mixture into a hydrogenation reaction zone; conducting hydrogenation in turn with a hydrogenation protective catalyst, a hydrofining catalyst and a hydro-upgrading catalyst A by contact; sending the hydrotreating effluent into a hydro-upgrading reaction zone using a hydro-upgrading catalyst B containing amorphous silica-alumina and modified Y zeolite, and carrying out a hydrogenation reforming reaction in the presence of hydrogen; sending the hydro-upgrading effluents into a hydrofinishing reaction zone, carrying out a hydrofinishing reaction and isolating hydrofinishing products to obtain the aviation kerosene with large proportion. The method uses catalytic recycle oil as raw material to produce the aviation kerosene with large proportion, high density, high volume calorific value, low aromatic content and good low temperature performance in the maximum amount, and can broaden the sources of raw materials for aviation kerosene products with large proportion.

Owner:CHINA PETROLEUM & CHEM CORP +1

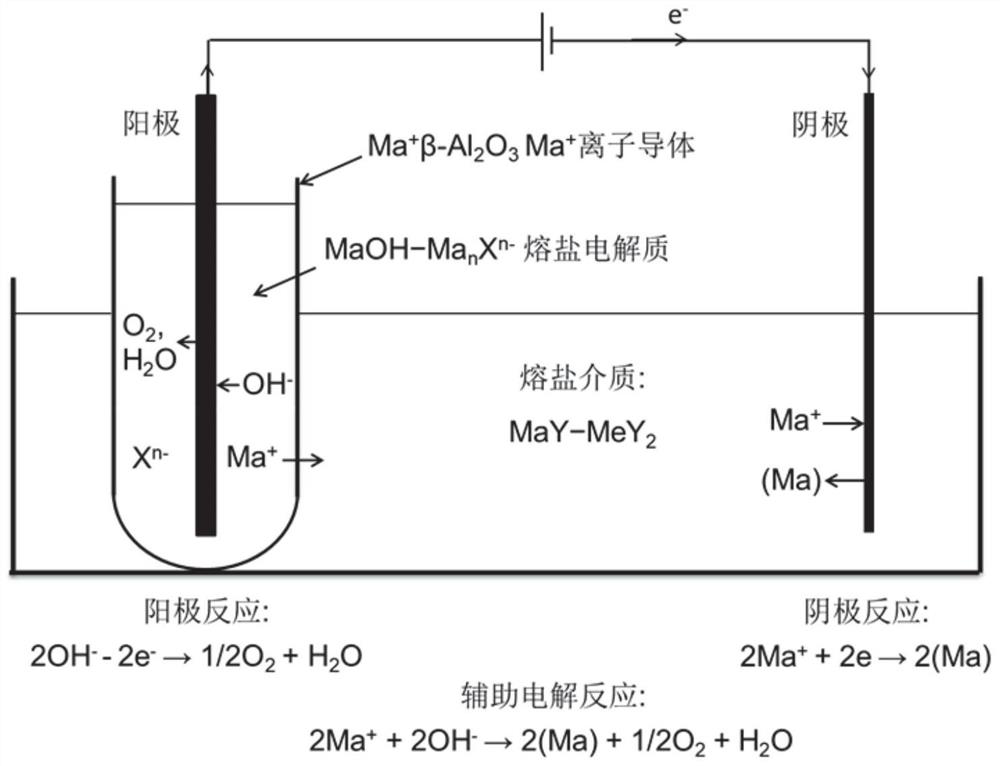

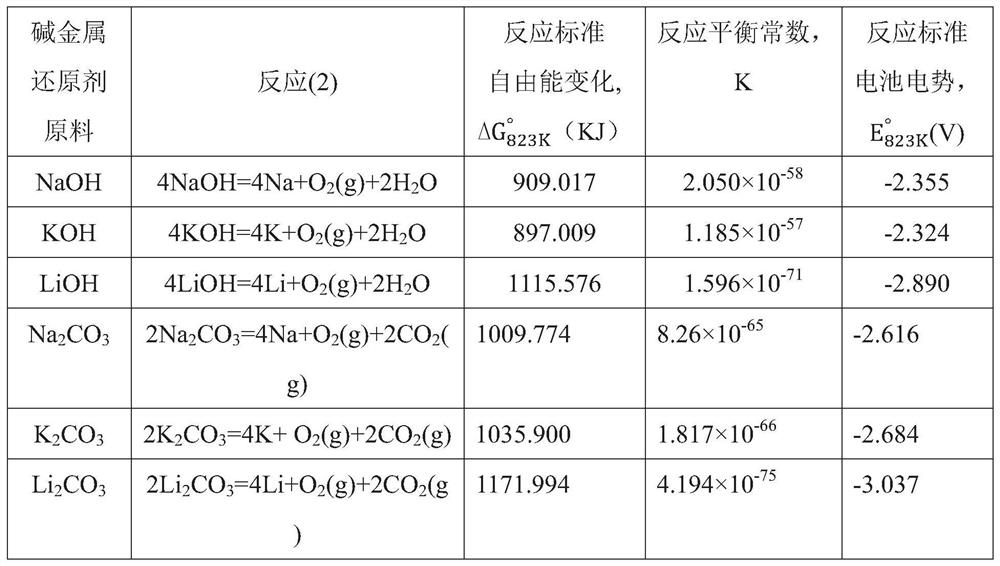

A kind of reducing molten salt medium and preparation method thereof

The invention relates to the technical field of metal material preparation, and specifically discloses a reducing molten salt medium and a preparation method thereof. The preparation method of described reducing molten salt medium, it uses mixed salt MaOH-Ma 2 CO 3 ‑MaCl as raw material, mixture MaY‑MeY 2 Flux for molten salt medium; MaOH‑Ma 2 CO 3 ‑MaCl melts to form MaOH‑Ma 2 CO 3 ‑MaCl molten salt, put into molten MaY‑MeY 2 In the molten salt medium flux, the electrolytic reaction is carried out to obtain the described reducing molten salt medium; the described reducing molten salt medium is MaY-MeY 2 ‑Ma; wherein, Ma represents an alkali metal; Me represents an alkaline earth metal; Y represents a halogen element. The preparation method of the invention can effectively solve the problems of low production efficiency and high energy consumption in the preparation of metal materials in the prior art.

Owner:AUYONG ADVANCED MATERIALS TECH SHANGHAI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com