Etherification, catalysis and rectification method and device for increasing gasoline octane number

A gasoline octane number, catalytic rectification technology, applied in hydrocarbon distillation, petroleum industry and other directions, can solve the problems of heat can not be effectively utilized, generate hot spots, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

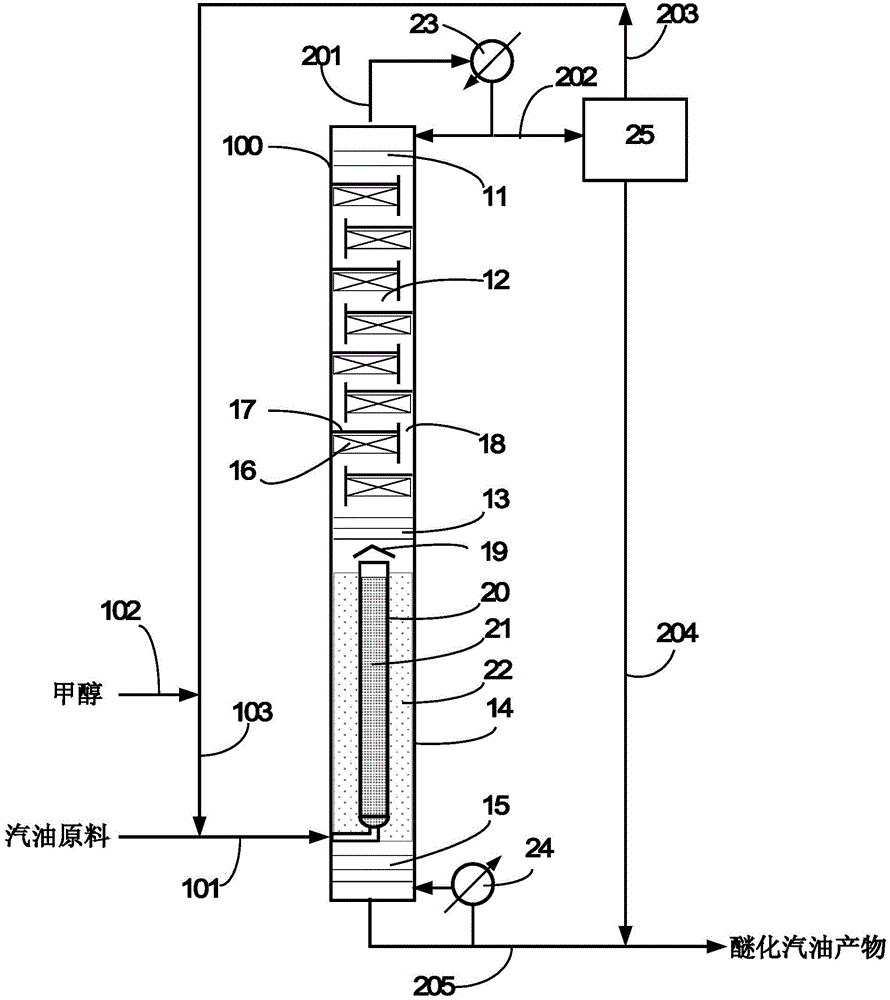

Embodiment 1

[0047] The catalytic rectification device used in this embodiment is as attached figure 1 As shown, the diameter of the catalytic rectification tower is 100mm, and the tower body is composed of a rectification section (11), a multi-stage unit catalytic fractionation section (12), an intermediate fractionation section (13), a shell-and-tube structure catalytic fractionation section (14) and a stripping section (15), the rectifying section has 2 tongue-shaped trays, and the multistage catalytic fractionation section includes 8 levels of reaction separation units, and each level of reaction separation units is composed of a bubble-cap tray with a downcomer (18) ( 17) and the catalyst component (16) that is fixed below the tray, the catalyst component is a stainless steel mesh bundled fiber woven bag filled with a macroporous sulfonic acid resin catalyst, the distance between each catalyst component and the tray below it is 80mm, and the middle fractionation section (13) There are...

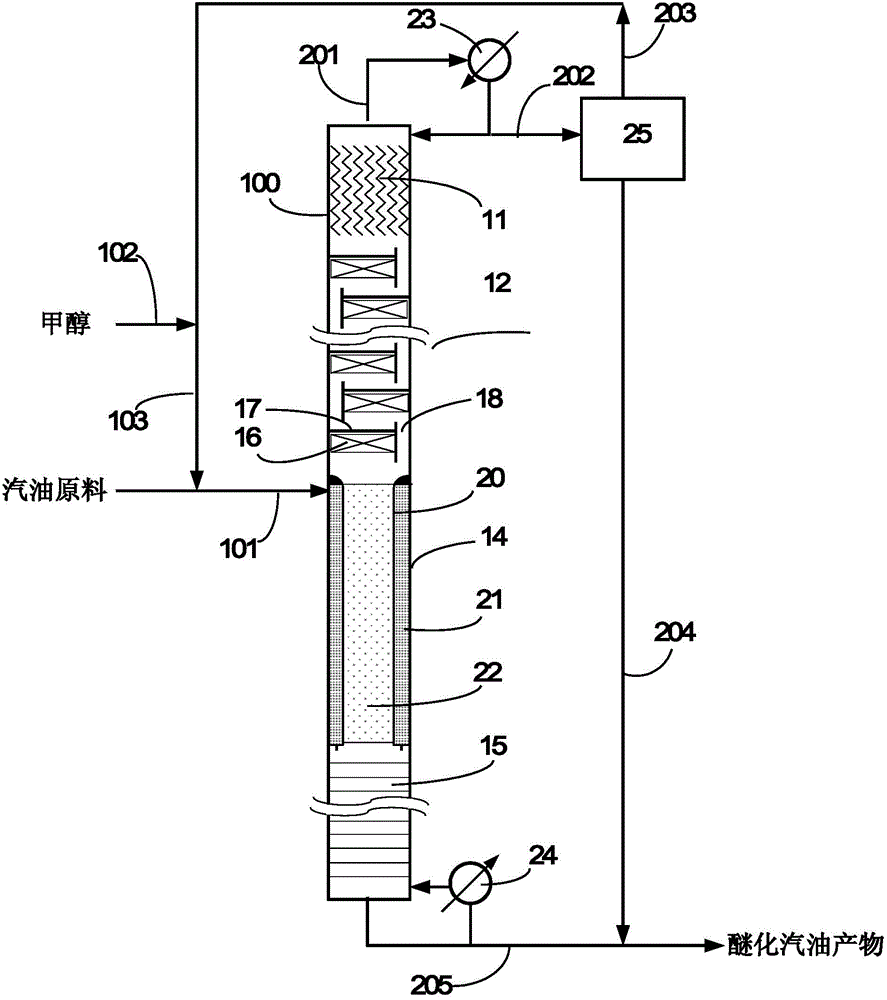

Embodiment 2

[0051] The catalytic rectification device used in this embodiment is as attached figure 2 As shown, the diameter of the catalytic rectification tower is 100mm, and the tower body is made up of rectifying section (11), multi-stage unit catalytic fractionation section (12), shell-and-tube structure catalytic fractionation section (14) and stripping section (15). The distillation section is packed with 500mm JWB-700Y packing. The multi-stage catalytic fractionation section includes 15 stages of reaction separation units, all of which are composed of tongue-shaped trays (17) with downcomers (18) and catalyst components (16) fixed below the trays. The component is a columnar stainless steel mesh basket filled with a macroporous sulfonic acid resin catalyst. The distance between each catalyst component and the tray below it is 50 mm. The height of the catalytic fractionation section (14) of the shell and tube structure is 800 mm. It consists of a straight inner pipe (20) and a jac...

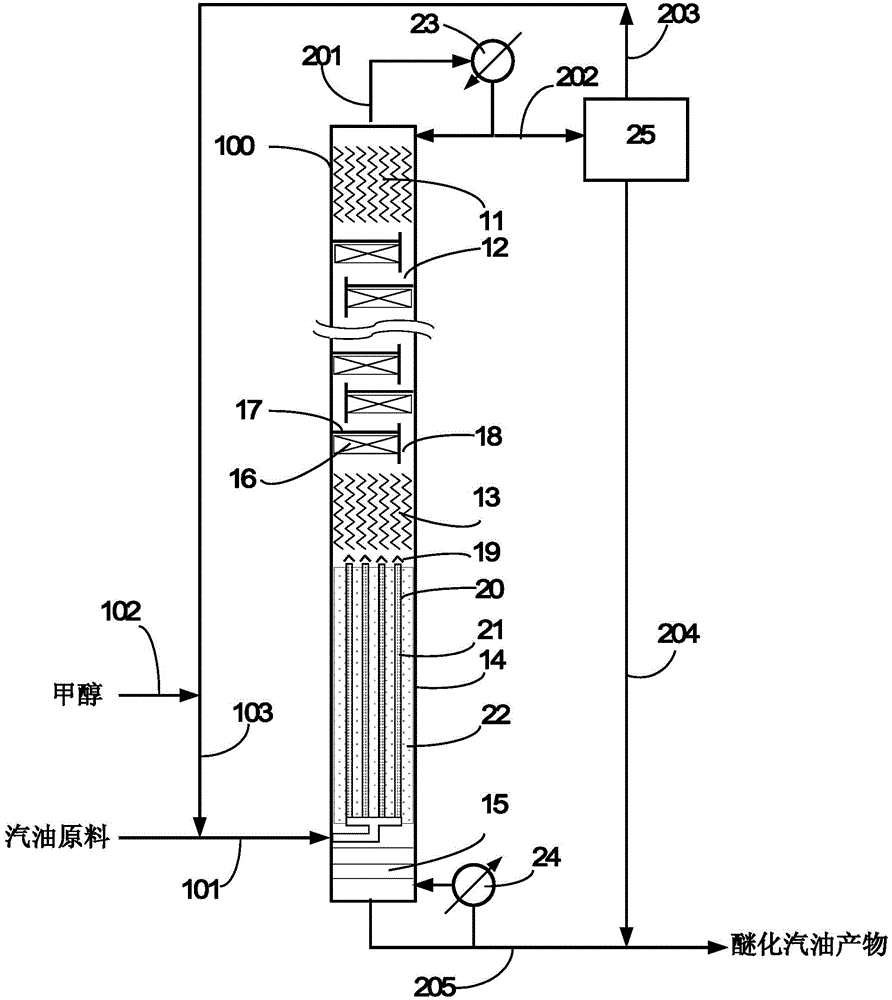

Embodiment 3

[0055] The catalytic rectification device used in this embodiment is as attached image 3 As shown, the diameter of the catalytic rectification tower is 100mm, and the tower body is composed of a rectification section (11), a multi-stage unit catalytic fractionation section (12), an intermediate fractionation section (13), a shell-and-tube structure catalytic fractionation section (14) and a stripping section (15), the rectifying section is packed with 500mm JWB-700Y packing, the multi-stage catalytic fractionation section includes 10 stages of reaction separation units, each stage of reaction separation units are composed of float valve trays (17) with downcomers (18) ) and the catalyst member (16) fixed below the tray, the catalyst member is a sandwich sandwich structure composed of stainless steel corrugated plates and cloth bags filled with solid macroporous sulfonic acid resin catalysts, the distance between each catalyst member and the tray below The middle fractionation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com