Process for preparing lubricating oil base oil through hydrogenation regeneration of waste lubricating oil

A technology for lubricating oil base oil and hydrogenation regeneration, which is applied in the fields of hydrotreating process, petroleum industry, lubricating composition, etc., can solve the problems of poor light stability of the regenerated base oil, inability to operate the device for a long period of time, catalyst poisoning, etc. Anti-coking ability, inhibition of grain growth, effect of increasing total acid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

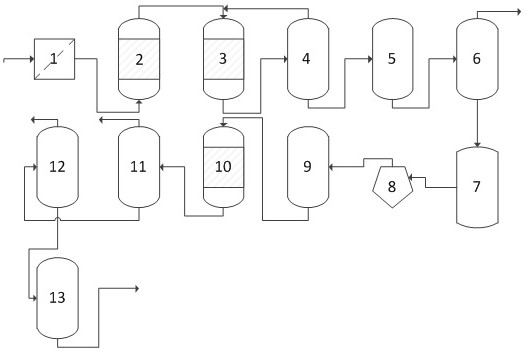

[0029] The raw material waste lubricating oil (see Table 1 for properties) first passes through the mechanical filtration device 1 to filter out large particles of impurities and remove most of the water in the raw material; 2-CaO-Al 2 o 3 Catalysts enter ebullating bed reactor 2 separately, in CO 2 content is N 2 In 20% gas by mass, the catalyst loading is 60% of the reactor volume, the reaction temperature is 160°C, and the volume space velocity is 7.0h -1 , under the condition of a pressure of 0.6MPa, a small amount of emulsified water and Cl in the waste lubricating oil are removed through the action of a catalyst; after dehydration and dechlorination, the lubricating oil enters the hydrofining reactor 3 under pressure, and the catalyst on the upper layer of the reactor is Ni-Mo-W -Ce / Al 2 o 3 The lower catalyst is Ni-Mo-P-La / Al 2 o 3 , at a reaction temperature of 320°C, a pressure of 8.0MPa, a volume ratio of hydrogen to oil of 300:1, and a liquid volume space vel...

Embodiment 2

[0031] The raw material waste lubricating oil (see Table 1 for properties) first passes through the mechanical filtration device 1 to filter out large particles of impurities and remove most of the water in the raw material; 2 -CaO-Al 2 o 3 Catalysts enter the ebullating bed reactor 2 respectively, under N 2 In the atmosphere, the catalyst loading is 78% of the reactor volume, the reaction temperature is 40°C, and the volume space velocity is 2.0h -1 , under the condition of a pressure of 0.2MPa, a small amount of emulsified water and Cl in the waste lubricating oil are removed through the action of a catalyst; after dehydration and dechlorination, the lubricating oil is pressurized and enters the hydrofining reactor 3, and the catalysts in the upper and lower layers of the reactor are Ni-Mo -P-La / Al 2 o 3 , at a reaction temperature of 280°C, a pressure of 3.0MPa, a volume ratio of hydrogen to oil of 100:1, and a liquid volume space velocity of 0.8h -1 Under the conditio...

Embodiment 3

[0033] The raw material waste lubricating oil (see Table 1 for properties) first passes through the mechanical filtration device 1 to filter out large particles of impurities and remove most of the water in the raw material; 2 -CaO-Al 2 o 3 Catalysts enter ebullating bed reactor 2 separately, in CO 2 content is N 2 In 10% gas by mass, the catalyst loading is 69% of the reactor volume, the reaction temperature is 300°C, and the volume space velocity is 10.0h -1 , under the condition of a pressure of 1.0MPa, a small amount of emulsified water and Cl in the waste lubricating oil are removed by the action of a catalyst; after dehydration and dechlorination, the lubricating oil enters the hydrofining reactor 3 under pressure, and the catalyst on the upper layer of the reactor is Ni-Mo-P -La / Al 2 o 3 The lower catalyst is Ni-Mo-W-Ce / Al 2 o 3 , at a reaction temperature of 360°C, a pressure of 5.0MPa, a hydrogen-oil volume ratio of 200:1, and a liquid volume space velocity of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com