System and control method for producing ammonia gas by hydrolyzing urea solution

A control method and urea technology, applied in the preparation/separation of ammonia, etc., can solve the problems of high medium temperature, high energy consumption, high investment cost, and achieve the effect of increasing inlet temperature, reducing operating cost, and simple and reliable system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

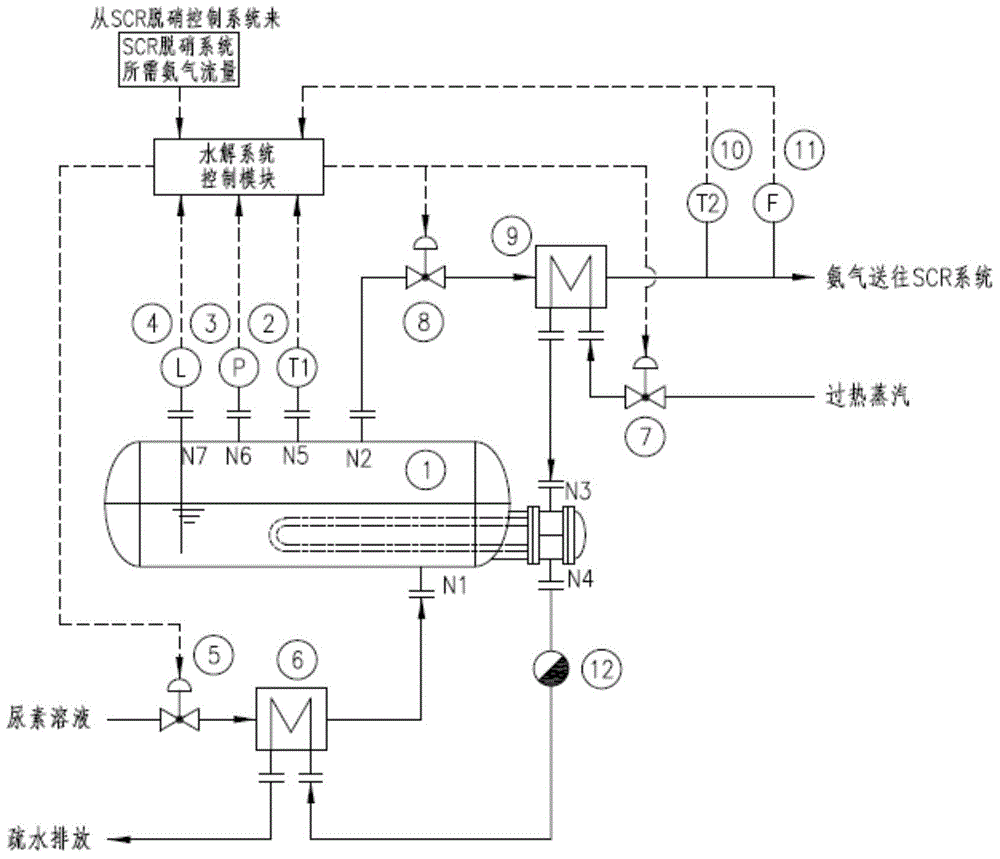

[0043] (1) see figure 1 , a system for hydrolyzing urea solution to produce ammonia, characterized in that it includes a hydrolyzer ①, a hydrolyzer thermometer T1②, a hydrolyzer pressure transmitter P③, a hydrolyzer liquid level gauge L④, a urea solution regulating valve A1⑤, a drain changer Heater ⑥, steam regulating valve A2⑦, hydrolysis gas outlet regulating valve A3⑧, steam heat exchanger ⑨, hydrolysis gas outlet thermometer T2⑩, hydrolysis gas outlet flow meter F⑾, steam trap ⑿ and hydrolysis system control module. The position connection relationship between them is: the hydrolyzer ① has 7 interfaces, which are described as follows:

[0044] The N1 interface is connected to the urea solution inlet pipe, which is used to supply the raw material - urea solution to the hydrolyzer ①. The urea solution inlet pipeline is provided with a urea ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com