Tail gas recovery system in the production of diketene

A diketene and tail gas recovery technology, which is applied in gas treatment, separation methods, and dispersed particle separation, etc., can solve the problems that ketene cannot be absorbed, ketene cannot be used, and energy loss in tail gas treatment is achieved, so as to improve the overall economic benefits, The effect of reducing energy consumption and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

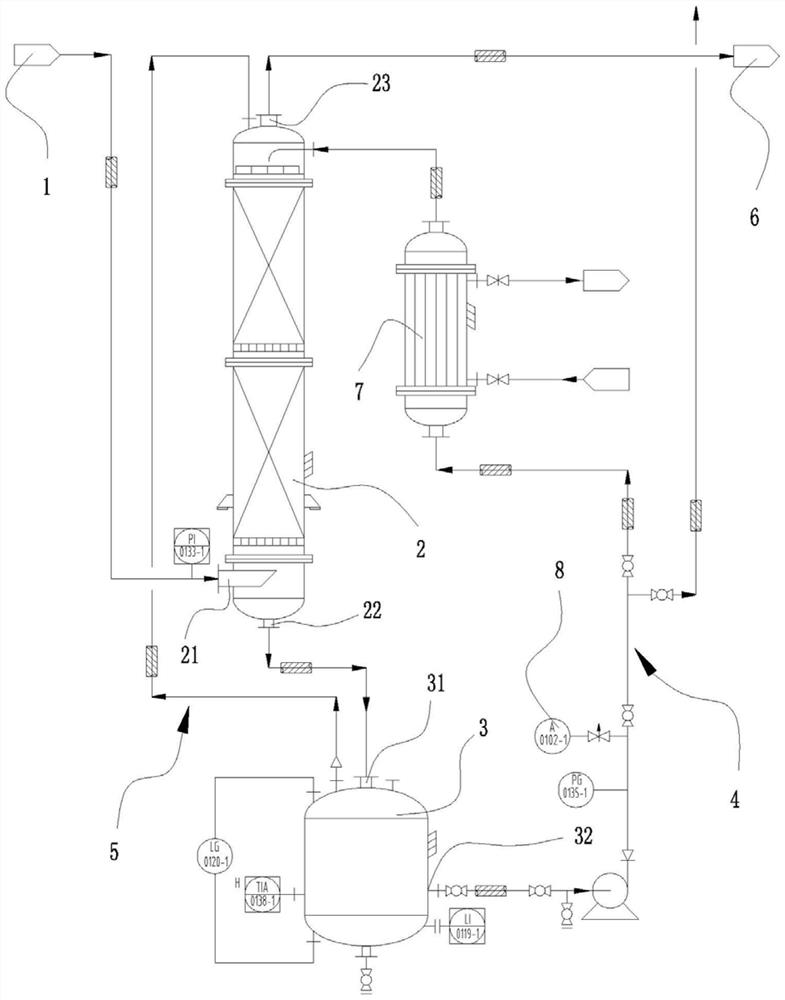

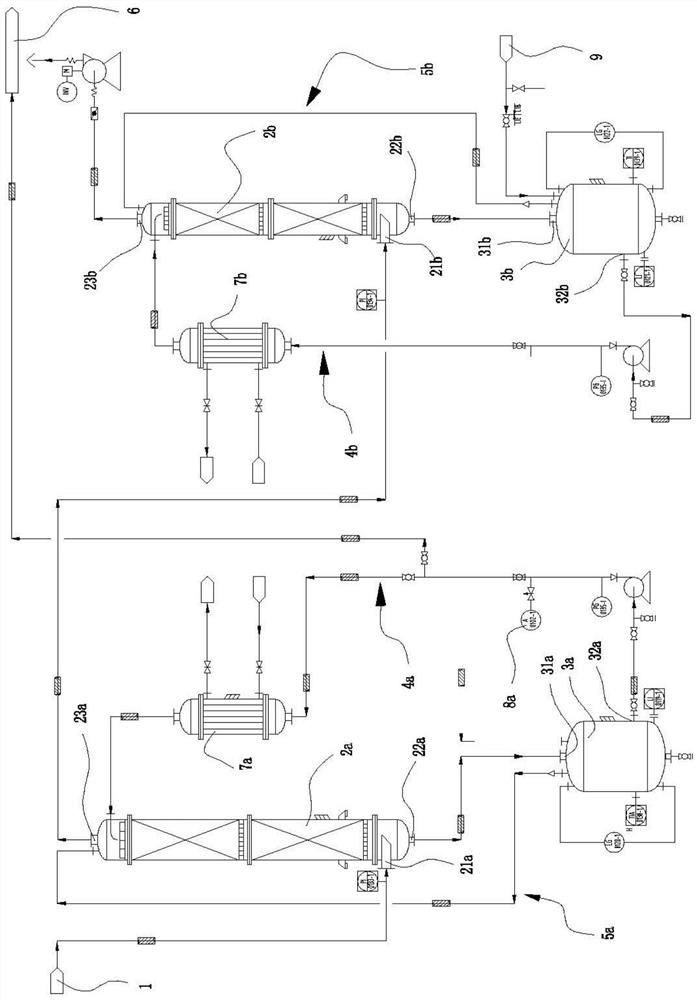

[0084] like figure 1 As shown, in the tail gas recovery system in the production of diketene in this embodiment, the tail gas absorption product receiving device imports the tail gas absorption product collected therein into the tail gas absorption device 2 as an absorption medium, and continues to absorb tail gas in the tail gas absorption device 2 . Through the tail gas recovery system in the production of diketene introduced in this embodiment, a cycle is established between the tail gas absorption device 2 and the tail gas absorption product receiving device 3, and the absorption medium discharged in the tail gas absorption device 2 repeatedly and repeatedly in the tail gas absorption device 2 Circulation between the tail gas absorption product receiving equipment 3, while increasing the absorption rate of the absorption medium for the active ingredients in the tail gas, it can also increase the concentration of the substance content in the absorption medium, so that the ac...

Embodiment 2

[0088] like figure 1 As shown, the difference between the tail gas recovery system in the production of diketene in this embodiment and the above embodiment is that the tail gas absorption device 2 includes: a feeding device 21, which is used to introduce the tail gas into the tail gas absorption device 2 and connect to the tail gas source 1 . The discharge device 22 is used to export the tail gas absorption product generated in the tail gas absorption device 2 , and communicates with the tail gas absorption product receiving device 3 . The gas outlet device 23 is used to lead out the tail gas not completely absorbed in the tail gas absorption device 2 .

[0089] Further, the tail gas absorbing device 2 in this embodiment also includes an absorbing medium introducing device, and the absorbing medium used to absorb tail gas is introduced into the inside of the tail gas absorbing device 2, and the absorbing medium introducing device communicates with the tail gas absorbing prod...

Embodiment 3

[0093] like figure 1 As shown, the difference between the tail gas recovery system in the production of diketene in this embodiment and the above embodiment is that the tail gas recovery system includes a gas phase balance device 5, and the gas phase balance device 5 communicates the tail gas absorption device 2 with the tail gas absorption product receiving device 3, The air pressure between the two can be balanced and a certain amount of gas-phase material exchange can be performed; further, the gas-phase balance device 5 connects the top of the tail gas absorption device 2 with the top of the tail gas absorption product receiving device 3 . Preferably, the gas phase equilibration device 5 includes a piping structure allowing gas circulation.

[0094] Through the tail gas recovery system in the production of diketene introduced in this example, gas phase balance equipment is added, and the gas phase balance equipment connects the gas phase between the tail gas absorption equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com