A method for producing biodiesel using supercritical alcohols

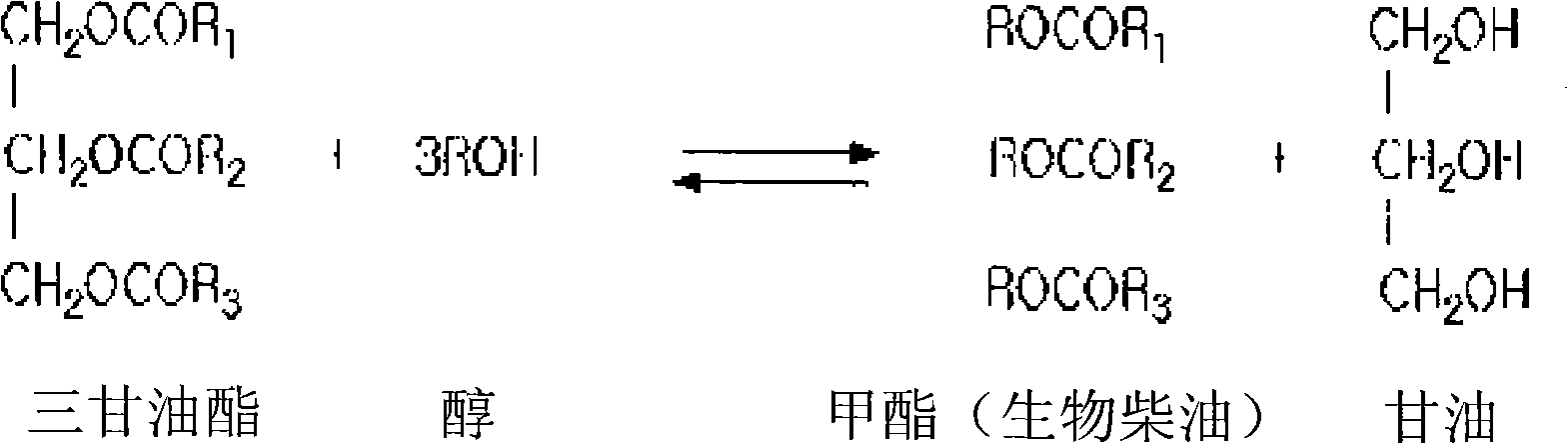

A biodiesel and supercritical technology, which is applied in the direction of biofuels, biological raw materials, fatty acid preparation/refining, etc., can solve the problems of inability to prepare biodiesel purity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

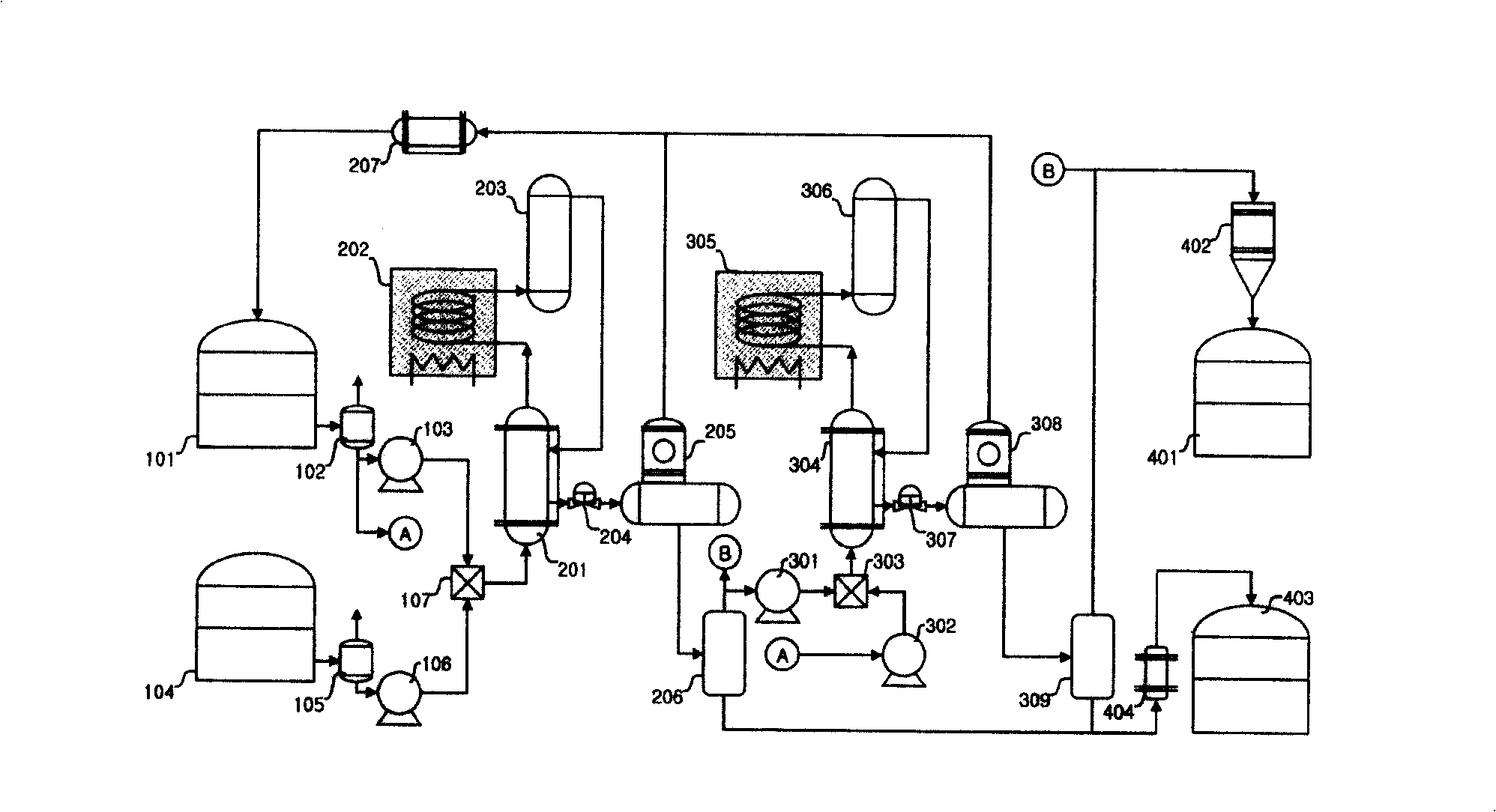

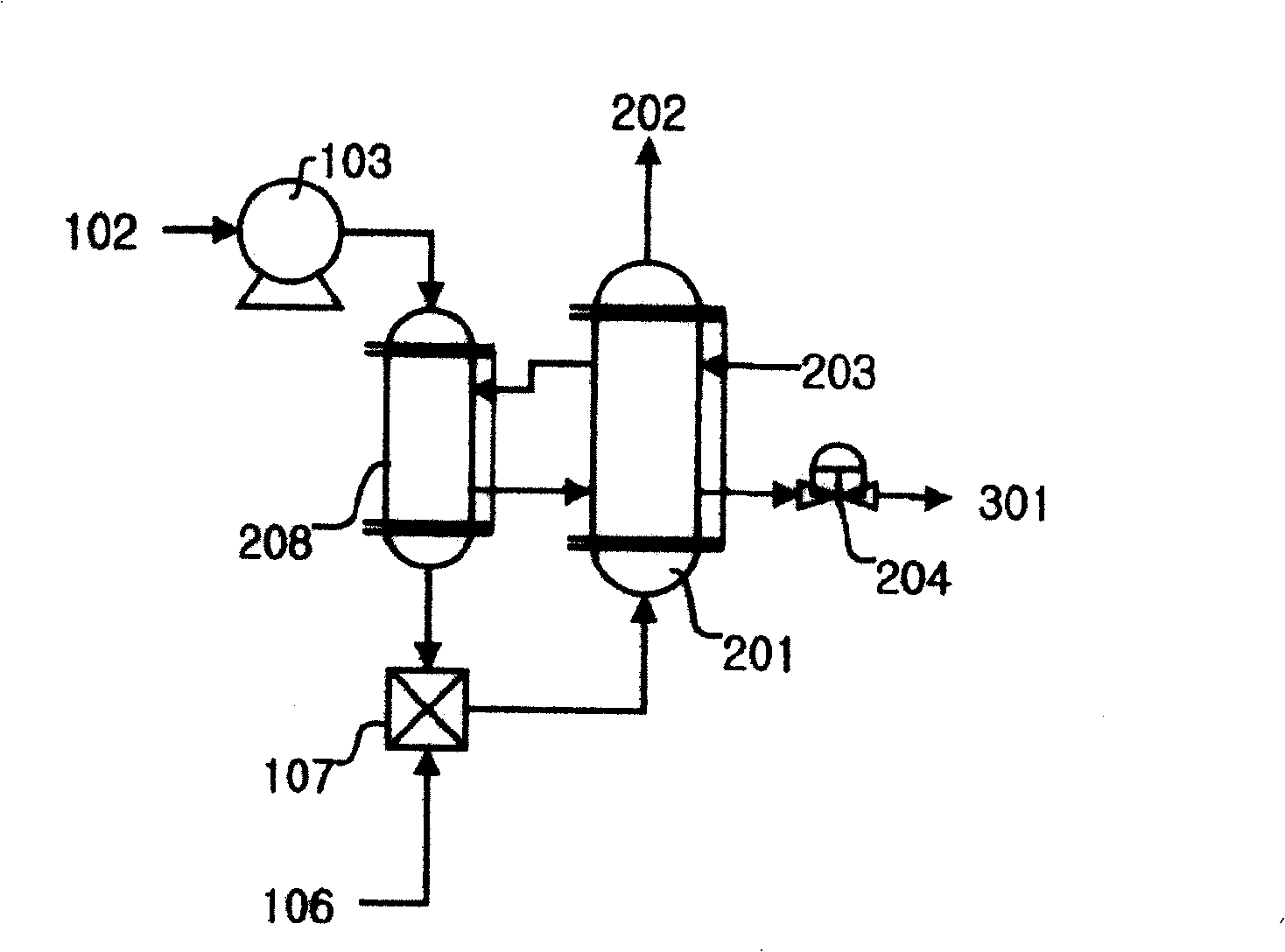

[0063] exist figure 1 Biodiesel is produced continuously in the system shown. The reactor used in this preparation is a tubular reactor.

[0064]After removing dissolved oxygen from the fat and alcohol as raw materials, the raw materials are pumped under pressure into a mixer where they are mixed with each other. The mixture is preheated to a predetermined temperature by means of heat exchangers and furnaces and maintained at the desired temperature in the reactor. Then, the reaction product was cooled in a cooler, its pressure was reduced through a pressure reducing valve, and a sample was collected from the product.

[0065] Here, the pressure of pumping the raw material is 80MPa to 200MPa, the preheating temperature is 80°C to 250°C, and the temperature of the reactor is 250°C to 400°C. Also, the reactor is a tubular reactor, and the residence time of the tubular reactor is 5 to 60 minutes.

[0066] In the production of biodiesel, the flow rate of the feedstock is volu...

Embodiment 30

[0092] Example 30: Preparation of biodiesel by secondary reaction

[0093] The fatty acid methyl ester obtained by the method of Example 1 was placed in the secondary reaction described in Example 1, and the content of fatty acid methyl ester in the product was analyzed. The product obtained in the primary reaction has a fatty acid methyl ester content of 78.7%, and the secondary reaction is carried out using the primary reaction product and methanol at a volume ratio of 1:1 under the following conditions: the reactor temperature is 350° C., the reactor pressure is 10 MPa, and the reactor residence time is 13 minutes. Analysis results showed that the content of fatty acid methyl ester in the secondary reaction product was 97.7%, and the total glycerol content (wt%) in the product was 0.028%. Here, the fatty acid methyl ester content was analyzed according to KS M 2413-2004, and the total glycerol content was analyzed according to KS M 2412-2004.

Embodiment 31

[0094] Example 31: Preparation of Biodiesel by Secondary Reaction

[0095] According to the same method as in Example 30, the raw material having 81.3% fatty acid methyl ester was placed in a secondary reaction, thus obtaining a product having 97.2% fatty acid methyl ester. The fatty acid methyl ester content was analyzed according to KS M2413-2004.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com