Extraction method for a segment of butadiene with NMP method

A technology for butadiene and C4 fractions, which is applied in the field of one-stage extraction of butadiene, can solve the problems of high refrigerant grade requirements and large heat load, and achieve the effects of improving operational safety, improving adaptability and simplifying the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

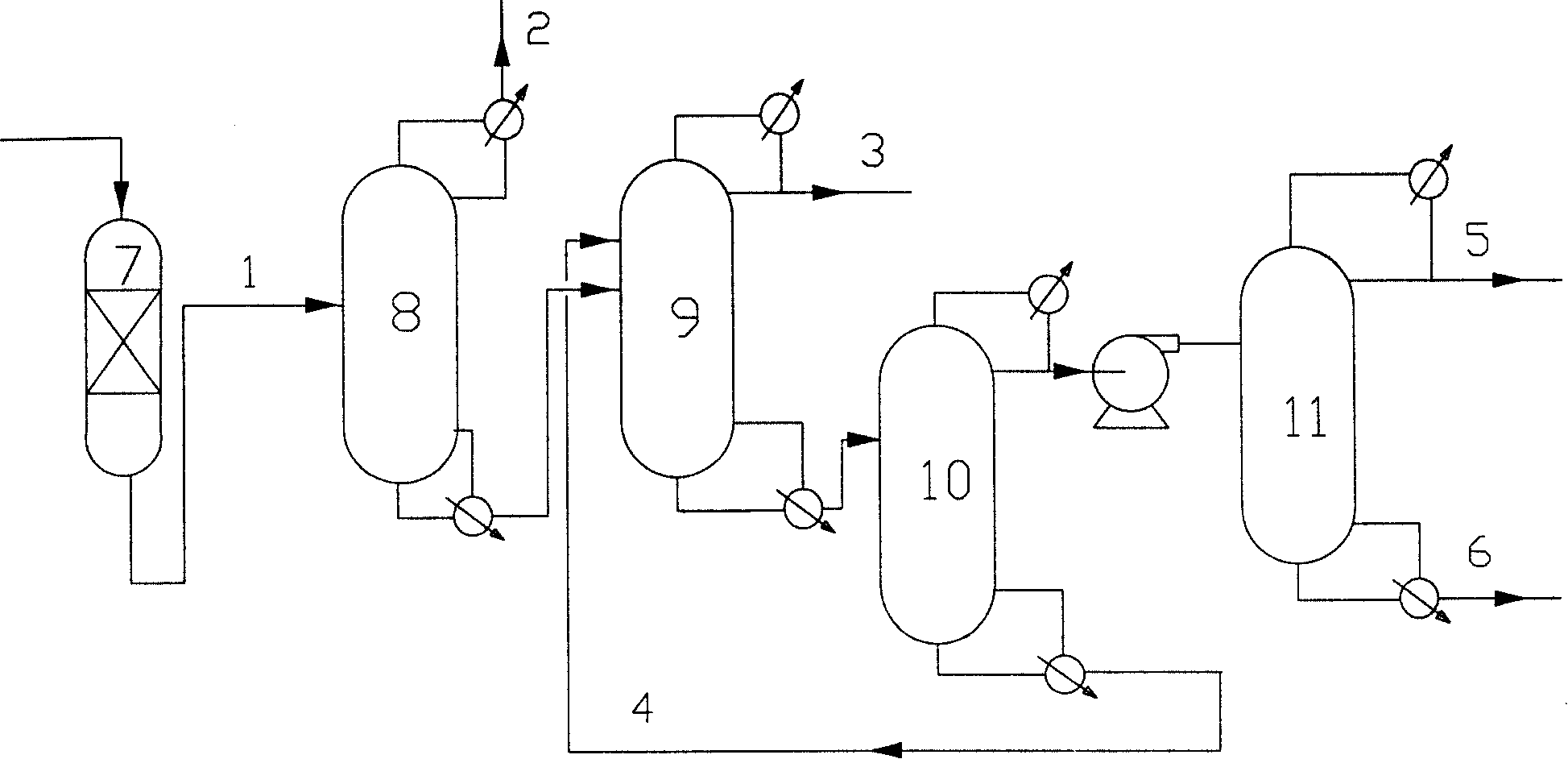

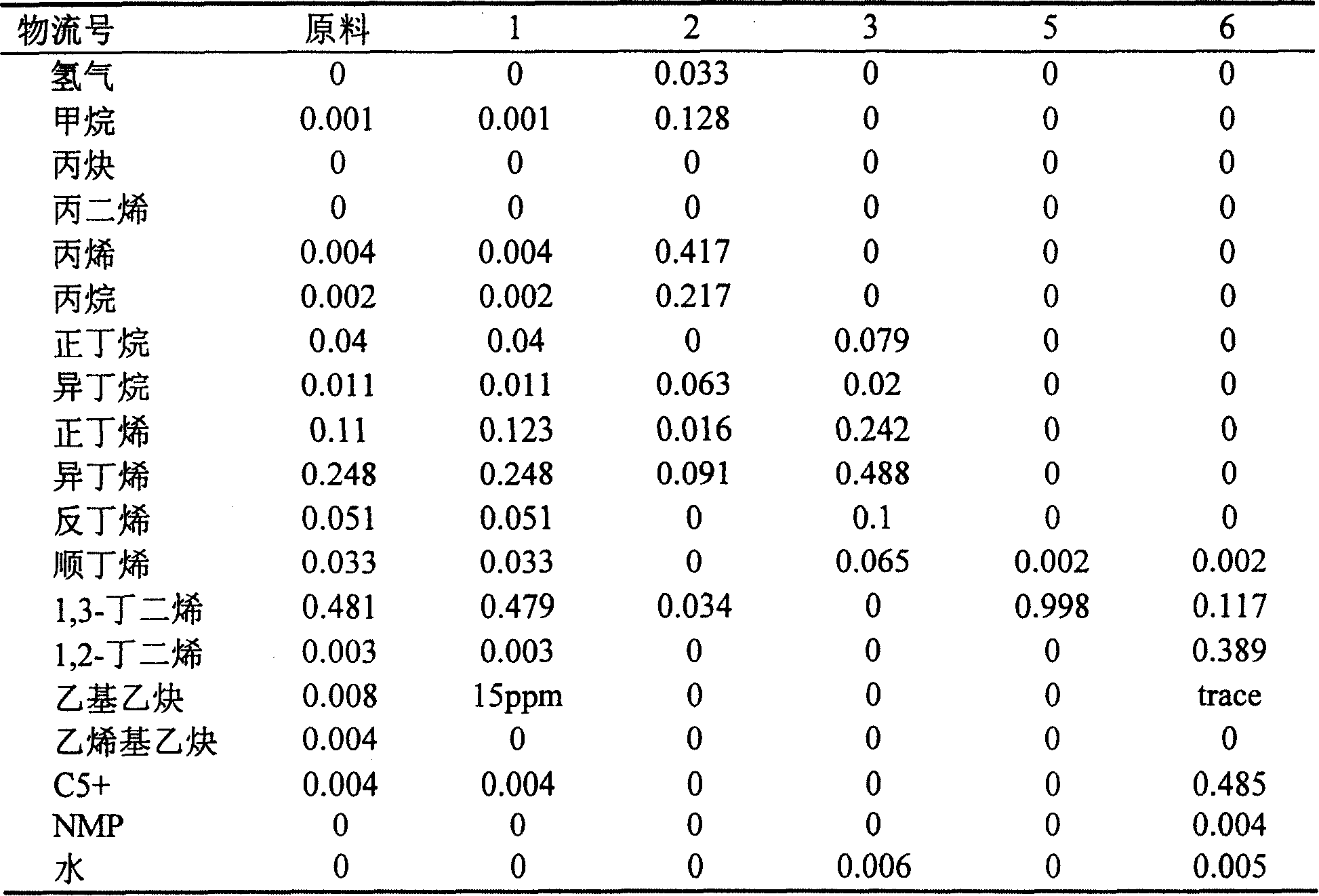

[0035] Refer below figure 1 The method of the present invention is further explained, but the present invention is not limited thereto.

[0036] One stage extraction method of NMP method butadiene of the present invention, comprises the following steps:

[0037] (1) Selective hydrogenation: the flow rate is 7830Kg / h liquid phase mixed C4 fraction (main composition: n-butane 4.0%, isobutane 1.1%, 1-butene 11.0%, isobutene 24.8%, 1,3- 48.1% of butadiene, 0.8% of ethyl acetylene, 0.4% of vinyl acetylene) and hydrogen are mixed in a ratio of 4.0 in the molar ratio of hydrogen to acetylene, with 3h -1 The volume hourly space velocity is fed into the reactor 7 from the top, and the catalyst loaded is the catalyst disclosed in the patent CN00107257.9, and the reaction temperature is 40°C and the pressure is 1.2MPa. The reaction is carried out, and the content of the mixed C4 fraction is 1.2% of alkynes were removed to 15 ppm.

[0038] (2) Removal of green oil: the reaction product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com