Paint of carbonless copy paper

A carbonless copy paper and coating technology, applied in the field of paper making, can solve the problems of easy white spots or fisheye paper, serious warping of copy paper, insufficient coating dispersibility, etc., achieve shortened preparation time, good printing adaptability, and less foam Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

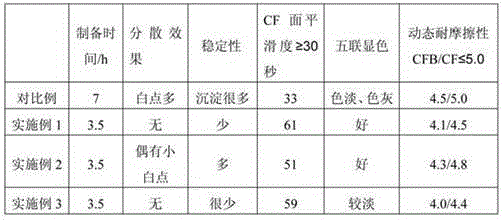

Examples

Embodiment 1

[0022] A coating for carbonless copy paper, its composition and proportion are:

[0023] First prepare glue and white material. The glue is prepared from 10.78g of tapioca starch, 0.86g of CMC, and 88.36g of water. The white material is made of 61.68g of washed paste kaolin, 9.85g of light calcium carbonate, 0.99g of dispersant, and 27.1g of water. , Prepared from 0.49g of alkali.

[0024] Then use the above glue and white material to prepare CB material and CF material:

[0025] The CB material is made of 22 g of glue, 6.75 g of wheat starch, 20 g of microcapsules, 0.375 g of styrene-butadiene latex and 50.875 g of water;

[0026] The CF material is made of 23g of glue, 33.6g of white material, 0.25g of dispersant, 7.25g of color developer, 1.8g of styrene-butadiene latex, 0.4g of lubricant, and 33.7g of water;

[0027] The obtained CB material and CF material are coatings for producing carbonless copy paper.

Embodiment 2

[0029] A coating for carbonless copy paper, its composition and proportion are:

[0030] First, prepare glue and white material. The glue is prepared from 10 g of tapioca starch, 0.5 g of CMC, and 85 g of water. The white material is made of 60 g of water-washed paste-like kaolin, 9 g of light calcium carbonate, 0.99 g of dispersant, 27.5 g of water, and 0.6 g of alkali. g prepared.

[0031] Then use the above glue and white material to prepare CB material and CF material:

[0032] The CB material is made of 22.5 g of glue, 6 g of wheat starch, 20 g of microcapsules, 0.3 g of styrene-butadiene latex and 50 g of water;

[0033] The CF material is made of 23.5g of glue, 33g of white material, 0.2g of dispersant, 7g of color developer, 1.5g of styrene-butadiene latex, 0.45g of lubricant, and 33g of water;

[0034] The obtained CB material and CF material are coatings for producing carbonless copy paper.

Embodiment 3

[0036] Firstly, glue and white material are prepared. The glue is prepared from 12 g of tapioca starch, 1 g of CMC, and 90 g of water. The white material is made of 62 g of washed paste kaolin, 10 g of light calcium carbonate, 0.99 g of dispersant, 28 g of water, and 1.0 g of alkali Prepared.

[0037] Then use the above glue and white material to prepare CB material and CF material:

[0038] The CB material is made of 23 g of glue, 7 g of wheat starch, 22 g of microcapsules, 0.5 g of styrene-butadiene latex and 52 g of water;

[0039] The CF material is made of glue 24g, white material 34g, dispersant 0.3g, developer 8g, styrene-butadiene latex 2.0g, lubricant 0.5g, water 35g;

[0040] The obtained CB material and CF material are coatings for producing carbonless copy paper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com