Preparation of calcium carbonate for carbon-free copying paper paint

A carbonless copy paper, calcium carbonate technology, applied in the direction of calcium carbonate/strontium/barium, pigment-containing coatings, etc., can solve the problems of slow color development and low smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

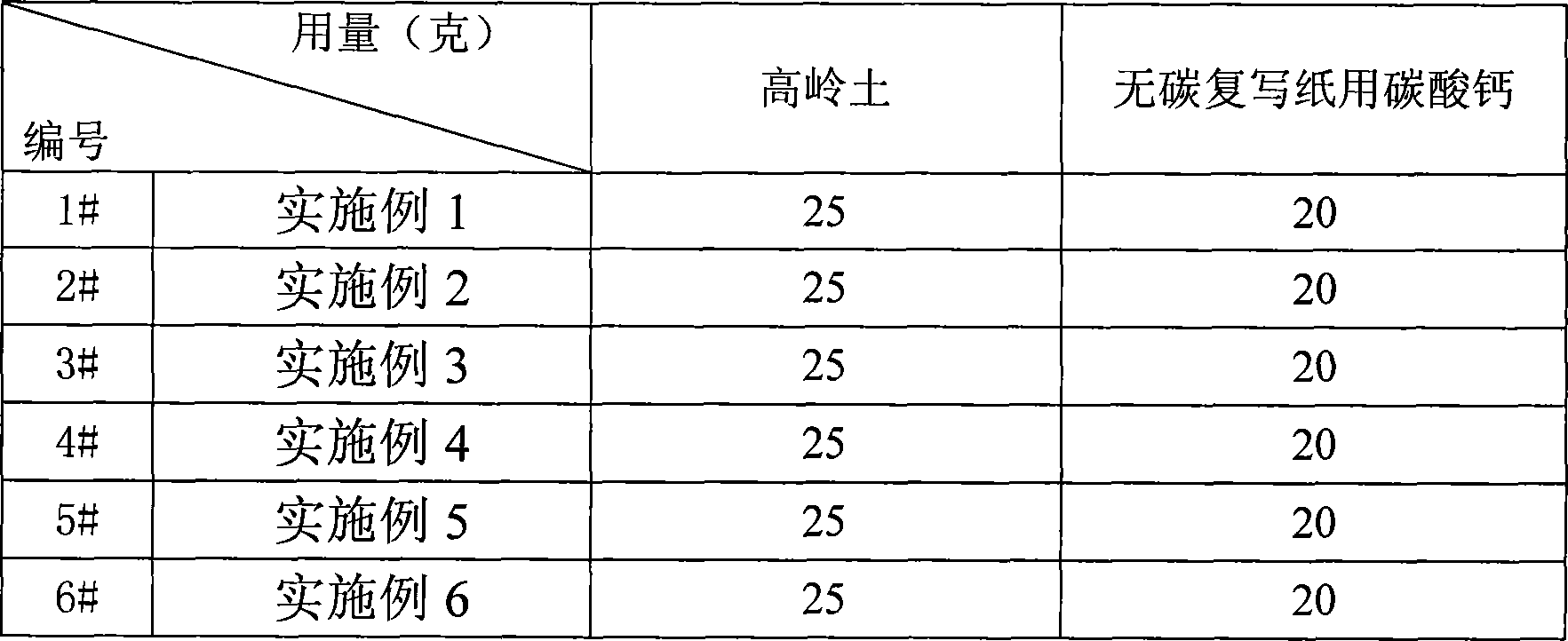

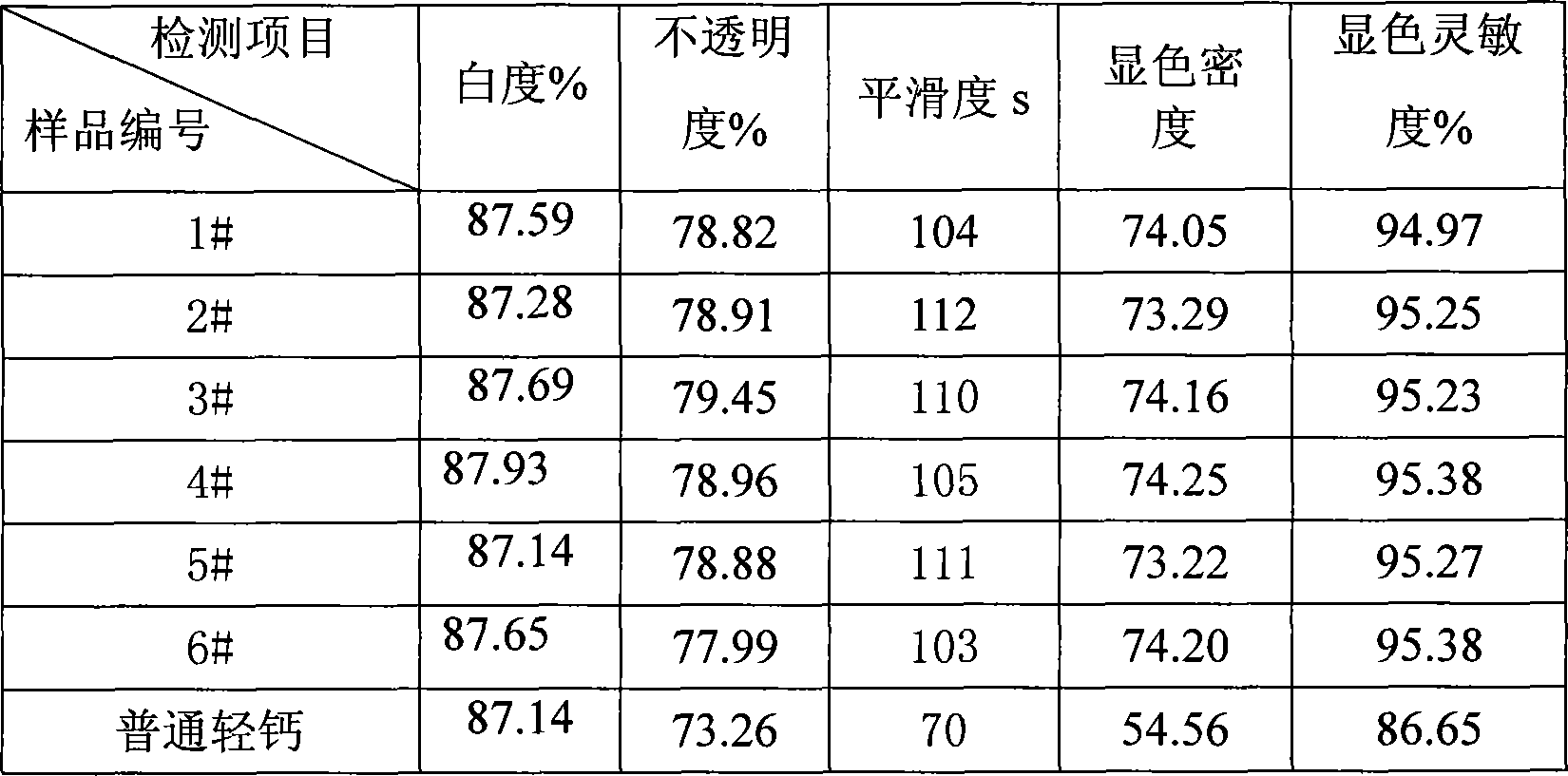

Examples

Embodiment 1

[0020] Weigh 40kg of aluminum sulfate, add 200kg of water into a 1 cubic meter reactor, and add 40kg of aluminum sulfate into a stirred 1 cubic meter reactor to make an aluminum sulfate solution.

[0021] Add 8000kg of calcium hydroxide slurry with a solid content of 20% into a carbonization tower with a stirring and cooling water jacket of 12 cubic meters, add 165 kg of the above-mentioned aluminum sulfate solution to the carbonization tower, stir for 20 minutes, and pour into the carbonization tower Feed in a mixed gas containing 10% (volume) of carbon dioxide, and use cooling water to control the temperature of the calcium hydroxide slurry at 10°C. When the carbonization to pH is 7.3, calcium carbonate slurry is obtained for carbonless copy paper coating, and the calcium carbonate slurry is filtered and washed with a plate and frame filter press to obtain a carbonless copy paper coating calcium carbonate product with a solid content of 50% filter cake 4260kg.

Embodiment 2

[0023] Weigh 30 kg of aluminum chloride, add 200 kg of water into a 1 cubic meter reactor, and add 30 kg of aluminum chloride into a stirred 1 cubic meter reactor to prepare an aluminum chloride solution.

[0024] 8000kg of calcium hydroxide slurry with a solid content of 5% is added to a carbonization tower with a stirring and cooling water jacket of 12 cubic meters, and 150 kg of the above-mentioned aluminum chloride solution is added to the carbonization tower, stirred for 50 minutes, and poured into the carbonization tower Pass into the mixed gas containing carbon dioxide 35% (volume), and control the temperature of the calcium hydroxide slurry at 40° C. with cooling water. When the carbonization to pH is 7.1, the calcium carbonate slurry for carbonless copy paper coating is obtained, and the calcium carbonate slurry is filtered and washed with a plate and frame filter press to obtain a carbonless copy paper coating calcium carbonate product with a solid content of 50% filt...

Embodiment 3

[0026] Weigh 100 kg of aluminum nitrate, add 350 kg of water to a 1 cubic meter reactor, and add 100 kg of aluminum nitrate to a stirred 1 cubic meter reactor to prepare an aluminum nitrate solution.

[0027] Add 8000kg of calcium hydroxide slurry with a solid content of 15% into a carbonization tower with a stirring and cooling water jacket of 12 cubic meters, add 250 kg of the above-mentioned aluminum nitrate solution to the carbonization tower, stir for 2 hours, and pour into the carbonization tower Feed in a mixed gas containing 18% (volume) of carbon dioxide, and control the temperature of the calcium hydroxide slurry at 20° C. with cooling water. When the carbonization to pH is 7.2, calcium carbonate slurry is obtained for carbonless copy paper coating, and the calcium carbonate slurry is filtered and washed with a plate and frame filter press to obtain a carbonless copy paper coating calcium carbonate product with a solid content of 51% filter cake 2980kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com