Environment-friendly microcapsule of carbonless copy paper and preparing method thereof, coating of carbonless copy paper

A technology of carbon-free copy paper and microcapsules, which is applied in the field of papermaking, can solve problems such as physical impact and strong pollution, and achieve the effects of reducing pollution, improving color rendering density, and clear writing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of described carbon-free copy paper environment-friendly microcapsules is:

[0032] 1. Dissolve 2 to 10 parts of colorless dye in 20 to 80 parts of environmentally friendly solvent oil under heating to obtain a core material;

[0033] 2. Add the core material prepared in step 1 and 2-10 parts of emulsifier into 10-100 parts of water, stir well and carry out preliminary emulsification, and add 6-15 parts of wall after reaching the expected particle size (2um-6um) material, stir well;

[0034] 3. Gradually raise the temperature of the emulsion obtained in step 2 to 65°C to 75°C while stirring, and then solidify and form it to make environmentally friendly microcapsules;

[0035] 4. Finally, adjust the pH of the environment-friendly microcapsules to 7.5-10 with a pH regulator and store them for later use.

[0036] At the same time, the present invention also provides a carbonless copy paper coating containing the above-mentioned environment-friendl...

Embodiment 1

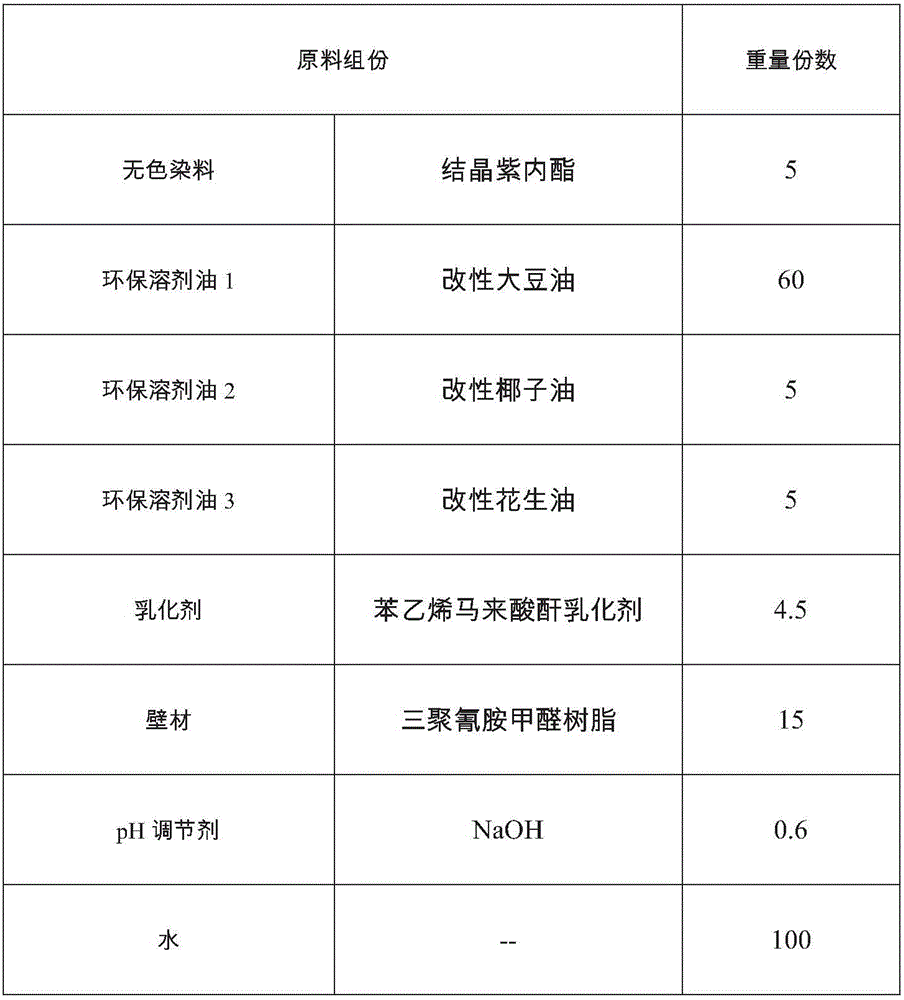

[0041] The specific composition of the environmental-friendly microcapsules for carbonless copy paper of Example 1 is shown in Table 1:

[0042] Table 1 Composition of environmental protection microcapsules

[0043]

[0044] The preparation of the environmental protection microcapsules for carbonless copy paper of embodiment 1 has the following steps:

[0045] 1. Dissolve 5 parts of colorless dye crystal violet lactone in 70 parts by weight of environmentally friendly solvent oil (including 60 parts of modified soybean oil, 5 parts of modified coconut oil, and 5 parts of modified peanut oil) under heating conditions , to get the core material;

[0046] 2. Add the obtained core material and 4.5 parts of styrene maleic anhydride emulsifier into 100 parts of water, stir well and then emulsify. After reaching the target particle size (2um~6um), add 15 parts by weight of wall material and stir thoroughly;

[0047] 3. Gradually raise the temperature of the above-mentioned emuls...

Embodiment 2

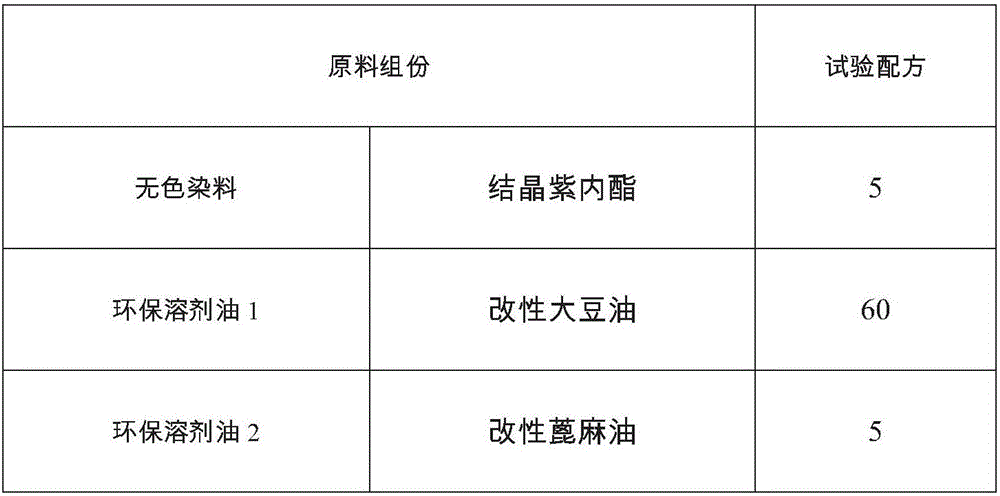

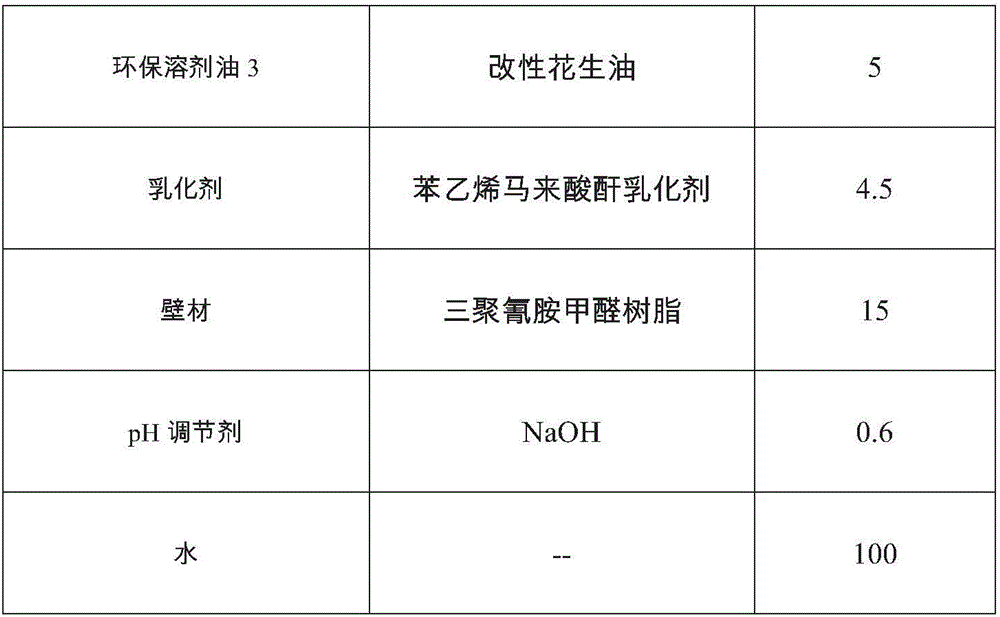

[0052] The environmental protection microcapsule formula of embodiment 2 is specifically referred to Table 2:

[0053] Table 2 composition of environment-friendly microcapsules

[0054]

[0055]

[0056]The preparation method of the environment-friendly microcapsule of embodiment 2 comprises the steps:

[0057] 1. Dissolve 5 parts of colorless dye in 70 parts of environmentally friendly solvent oil (including 60 parts of modified soybean oil, 5 parts of modified castor oil, and 5 parts of modified peanut oil) under heating conditions to obtain a core material;

[0058] 2. Add the above core material and 4.5 parts of emulsifier into 90 parts of water, stir well and then emulsify. After reaching the target particle size (2um ~ 6um), add 15 parts of wall material and stir fully;

[0059] 3. Gradually raise the temperature of the above-mentioned emulsion to 65°C to 75°C while stirring for curing and molding to make environmentally friendly microcapsules;

[0060] 4. Finall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com