Thermochromic paint and carbonless copy paper containing same

A carbonless copy paper, thermochromic technology, applied in paper coatings, textiles, papermaking, coatings, etc., can solve problems such as the limitation of application scope, and achieve the effect of good anti-counterfeiting effect, low cost and difficult to imitate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

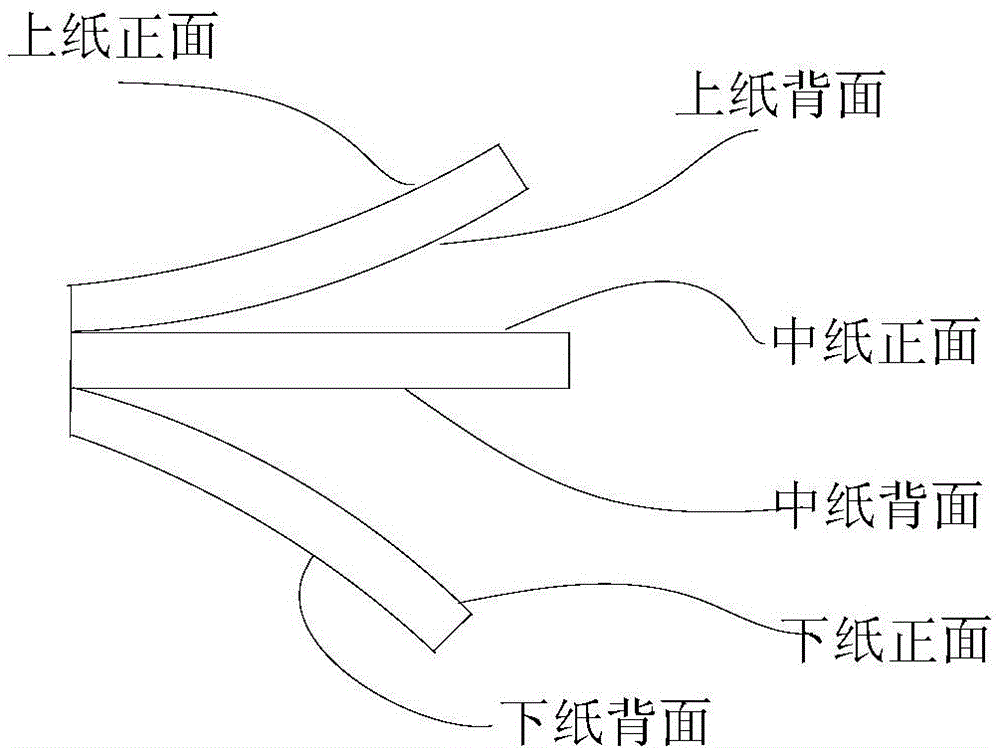

Image

Examples

Embodiment 1

[0044] 50 parts of China clay pigment; 50 parts of ground calcium carbonate; 20 parts of starch, 2 parts of rheological water-retaining agent polyamide; 1 part of styrene-butadiene latex; 1 part of water-resistant agent PAPU; 1 part of lubricant sulfated castor oil; Agent sodium hexametaphosphate 1 part; Surfactant sulfosuccinate 3 parts. Mix the above ingredients, add water and control the solid content to 23% to obtain a mixed paint, and finally add thermochromic microcapsules accounting for 1‰ of the mixed paint mass. Get thermochromic paint (SS paint).

[0045] The coating has a solid content of 23% and a viscosity of 18.4 cps.

Embodiment 2

[0047] 50 parts of China clay pigment; 50 parts of ground calcium carbonate (particle size 1-10 μm); 20 parts of corn starch; 2 parts of rheological water-retaining agent polyamide; 1 part of styrene-butadiene latex; 1 part of castor oil; 1 part of dispersant sodium hexametaphosphate; 3 parts of surfactant sulfosuccinate sodium salt sulfosuccinate. Mix the above ingredients into water and control the solid content to 23% to obtain a mixed paint, and finally add thermochromic microcapsules accounting for 3‰ of the mixed paint to obtain a thermochromic paint (SS paint).

[0048] The coating has a solid content of 23% and a viscosity of 18.5 cps.

Embodiment 3

[0050] 50 parts of China clay pigment; 50 parts of ground calcium carbonate (particle size 1-10 μm); 20 parts of corn starch; 2 parts of rheological water-retaining agent polyamide; 1 part of styrene-butadiene latex; 1 part of castor oil; 1 part of dispersant sodium hexametaphosphate; 3 parts of surfactant sulfosuccinate sodium salt sulfosuccinate. Mix the above ingredients, add water and control the solid content to 23%, to obtain a mixed coating, and finally add thermochromic microcapsules accounting for 4‰ of the mixed slurry mass. Get thermochromic paint (SS paint).

[0051] The coating has a solid content of 23% and a viscosity of 18.5 cps.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com