No carbon required paper microcapsule and coating, and preparation methods of no carbon required paper and microcapsule

A technology of carbon-free copy paper and microcapsules, applied in the direction of pigment-containing coatings, etc., can solve the problem that the color density of carbon-free copy paper cannot be reached, achieve pollution control, and improve the effect of color density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

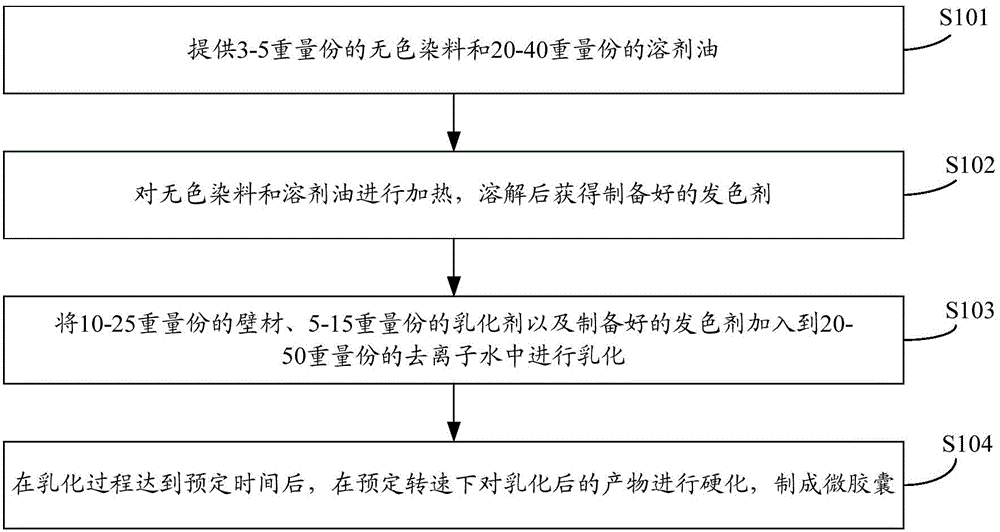

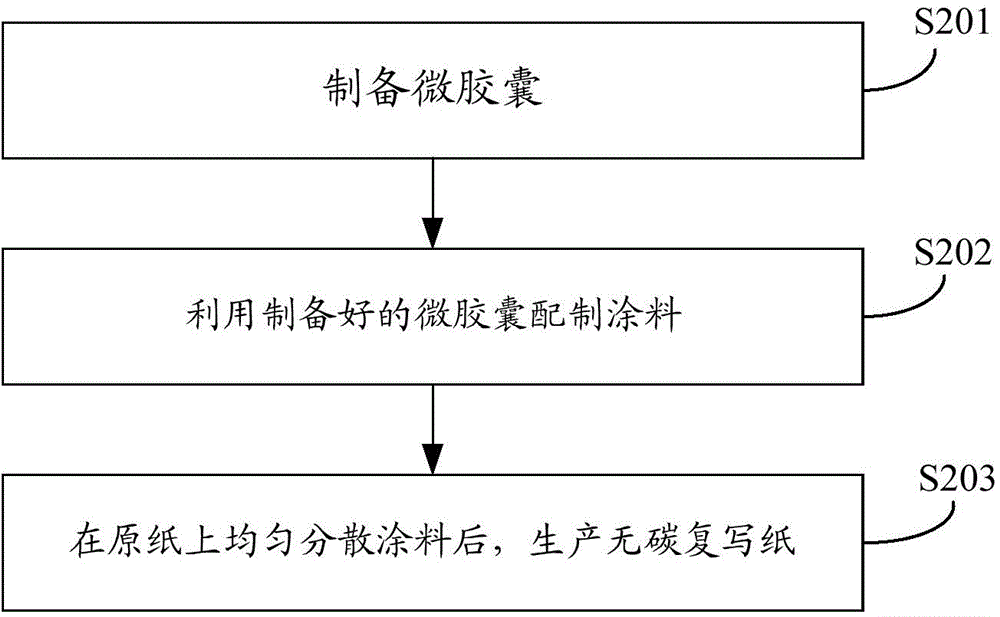

[0038] The present invention also provides a preparation method of microcapsules of carbonless copy paper, refer to figure 1 , the method includes:

[0039] Step S101: providing 3-5 parts by weight of leuco dye and 20-40 parts by weight of mineral spirits.

[0040] Step S102: heating the leuco dye and solvent naphtha, and obtaining the prepared chromogenic agent after dissolving.

[0041] Step S103: adding 10-25 parts by weight of the wall material, 5-15 parts by weight of the emulsifier and the prepared color developing agent into 20-50 parts by weight of deionized water for emulsification.

[0042] Step S104: After the emulsification process reaches a predetermined time, harden the emulsified product at a predetermined rotation speed to make microcapsules.

[0043] Both the predetermined time and the predetermined rotational speed are obtained through experimental verification. Under such preparation conditions, the prepared microcapsules are used to prepare carbonless cop...

Embodiment 1

[0068] Example 1: The color density is low.

Embodiment 2

[0069] Example 2: The color density is very high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com